Integrated Fischer-Tropsch synthetic oil hydrogenation purification

An integrated cost-effective, hydrogenation-upgrading technology, which is applied in the fields of hydrogenation treatment process, petroleum industry, and hydrocarbon oil treatment, can solve the problems of poor product quality, stability, and adverse effects of operation cycle, and achieve less equipment and improved Utilization and service life, the effect of reducing investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

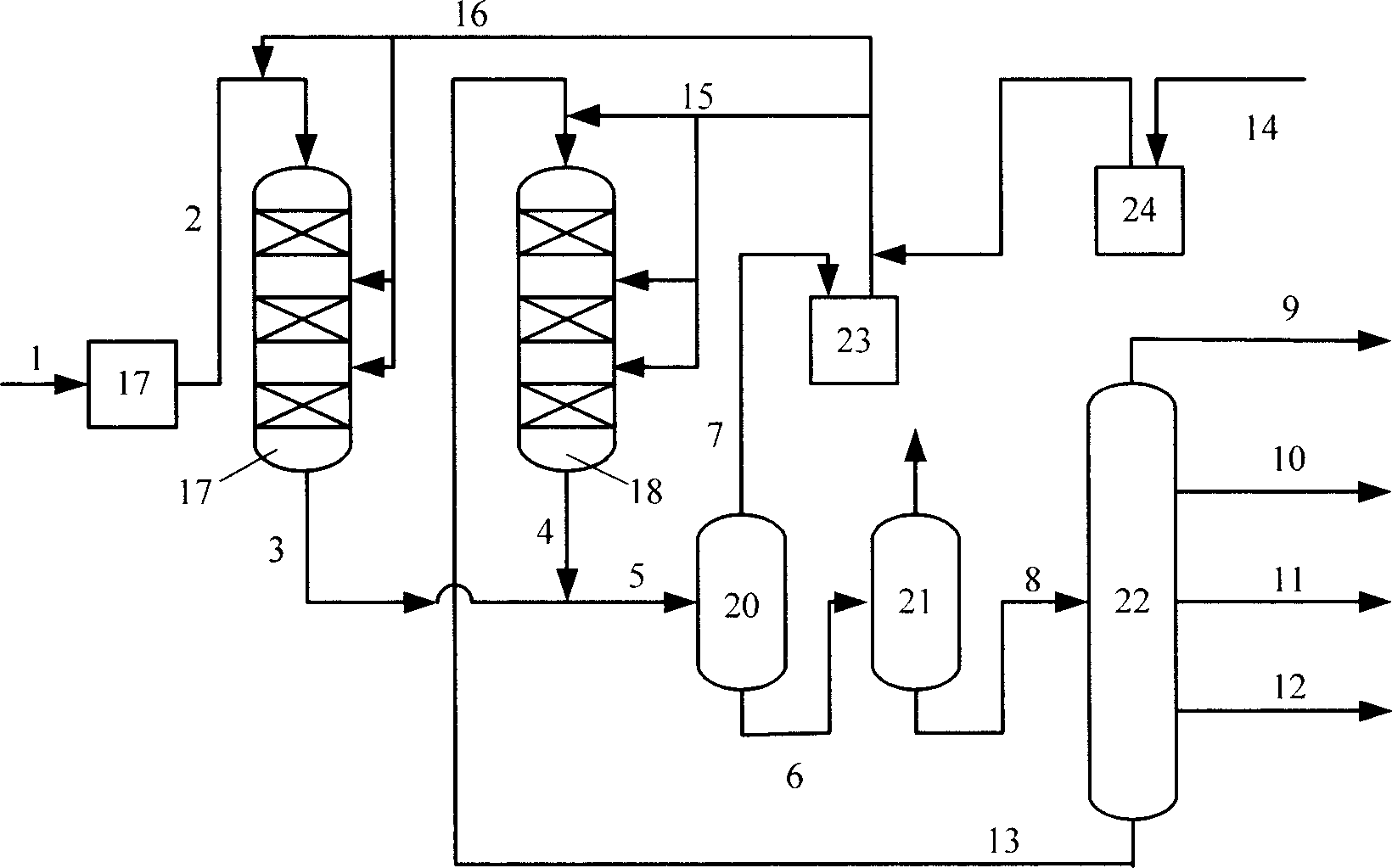

Method used

Image

Examples

Embodiment

[0039] The test catalysts and operating conditions are listed in Table 2, the properties of the product naphtha fraction are listed in Table 3, and the properties of the product diesel fraction are listed in Table 4.

[0040] It can be seen from the data in the table that using the method provided by the present invention, the hydrogen partial pressure is 6.4MPa, the hydrorefining reaction temperature is 300°C, the hydroisomerization cracking reaction temperature is 363°C, and the total volumetric space velocity is 2.0h. -1 , Processing Fischer-Tropsch synthetic full distillate oil under the condition of hydrogen-oil volume ratio of 800v / v can completely convert wax oil distillate into naphtha and diesel products. The yield of diesel product is high, 83.6% by weight, and its cetane number is 80, which can be blended with low cetane number diesel fraction; naphtha fraction is mainly composed of alkanes, which is a good raw material for steam cracking to produce ethylene .

[0041] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com