Dedusting device and dedusting method therefor

A technology of dust removal device and atomization device is applied in the field of industrial dust removal device and cyclone dust removal device to achieve the effect of saving water consumption, reducing energy consumption, and having little influence on physical and chemical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

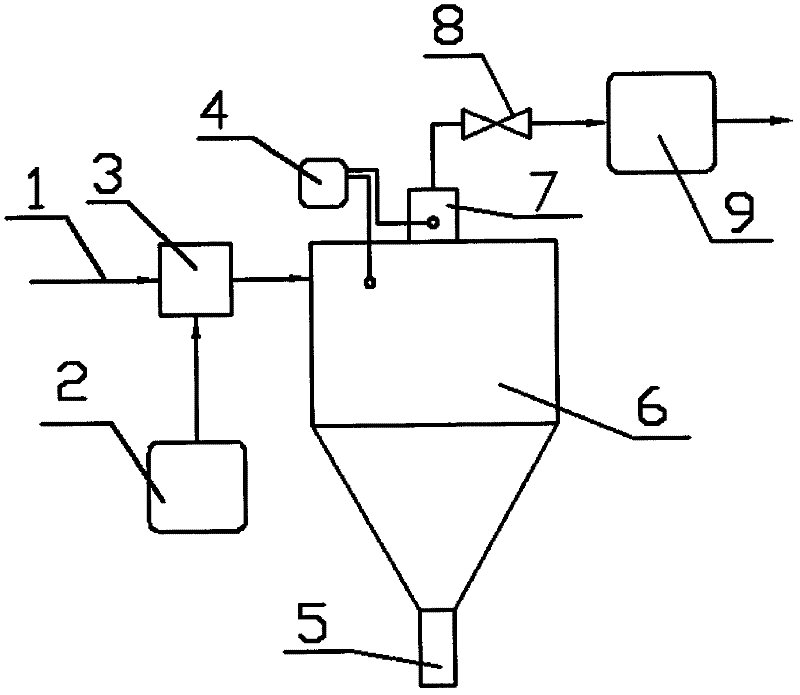

[0035] In this embodiment, the cement raw meal is used as the dust to be used, and the dust concentration is 66.22, 72.00, 76.06, 79.39, 83.89, 88.06g / m 3 The experiment was carried out at a temperature of 25°C.

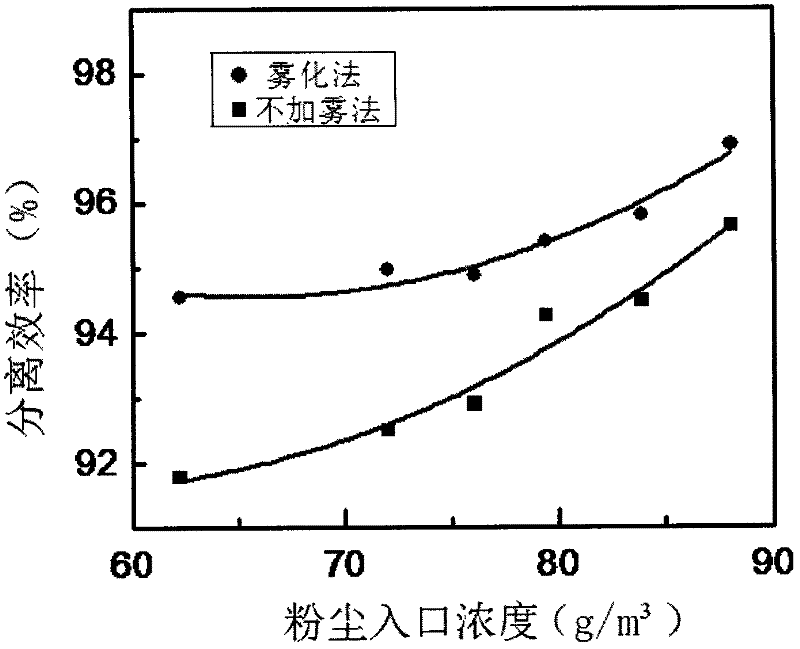

[0036] The experimental process is: open the ventilator 9, the wind speed is controlled by the valve 8 to 20m / s, the dusty gas is passed through the pipeline 1 into the cyclone separator 6 for separation, the clean gas is discharged through the air outlet 7, and the separated dust particles are discharged from the dust outlet. 5 discharge, the separation efficiency of different dust inlet concentrations by the non-fogging method is obtained from the amount of feed and output, and is drawn in image 3 in, see image 3 Curves without fogging.

[0037] Under the same conditions as above, turn on the ultrasonic atomizer 2 and adjust the atomization concentration to 8.33, 16.67, 25.00g / m 3 In the experiment, the mist and dusty gas are fully mixed and evenly mixed in th...

Embodiment 2

[0045] The dust particles used in the experiment are the same as in Example 1, and the dust inlet concentration is fixed at 76.06g / m 3 , with fog concentrations of 0, 8.33, 16.67, and 25.00g / m 3 Carry out experiments, other conditions remain unchanged, and measure the change of separation efficiency and pressure drop.

[0046] Image 6 It shows the relationship between the total separation efficiency and the mist concentration. As the mist concentration increases, the separation efficiency increases, but the growth trend slows down. Fog concentration from 0 to 16.67g / m 3 , water mist grows from scratch, and processes such as "cloud" physics occur, particles agglomerate, particle size increases, and separation efficiency increases significantly; the fog concentration increases from 16.67g / m 3 up to 25.00g / m 3 , although the mist content per unit weight of particles increases relatively, but the growth trend of separation efficiency slows down. The reason may be that for th...

Embodiment 3

[0050] The dust particles used in the experiment are kaolin, and the dust concentration is 59.83, 83.67g / m 3 conduct experiment. Experimental procedure is identical with the b, c method of embodiment 1, and draws Figure 9 .

[0051] Figure 9 Shown is the relationship between the inlet concentration of kaolin dust and the separation efficiency, it can be seen that Figure 9 and Example 1 image 3 The rules shown are basically the same. Therefore, the electro-acoustic transducer ultrasonic atomization method is suitable for the collection and separation of various dust particles, and has universal applicability.

[0052] Based on the above experiments, the corresponding processing control parameters can be determined as follows: when the flow rate of the dusty gas to be treated is 20m / s, the dust concentration of the dusty gas entering the mixing chamber should be controlled at no higher than 85g / m 3 , the mist concentration entering the mixing chamber is greater than 7....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com