Bionic drag reduction potato harvester digging shovel

A digging shovel and harvester technology, which is applied in the field of bionic drag-reducing potato harvester digging shovel, can solve the problems of low efficiency of excavating mechanism, poor ability to break soil, broken soil, and wear of sand and gravel, so as to improve the performance of drag reduction and desorption, The effect of improving the ability to penetrate into the soil and improving the drag reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

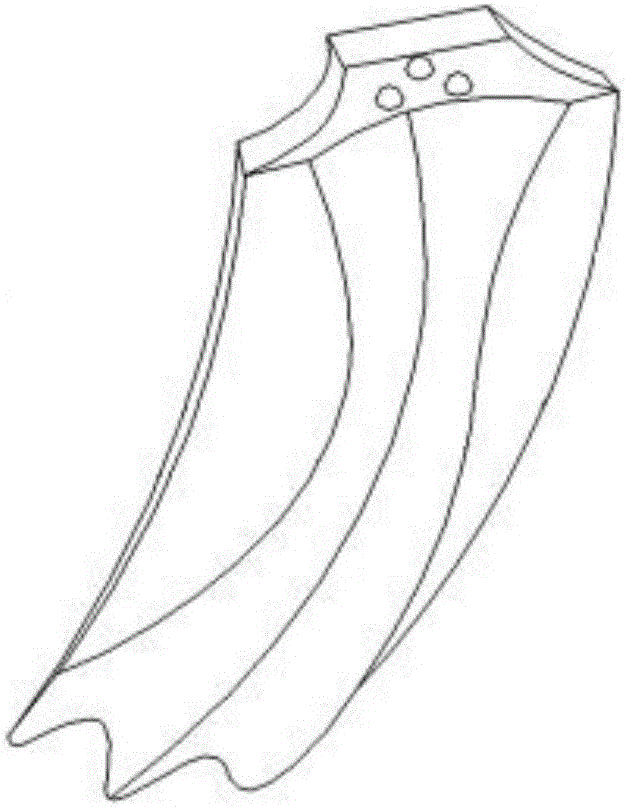

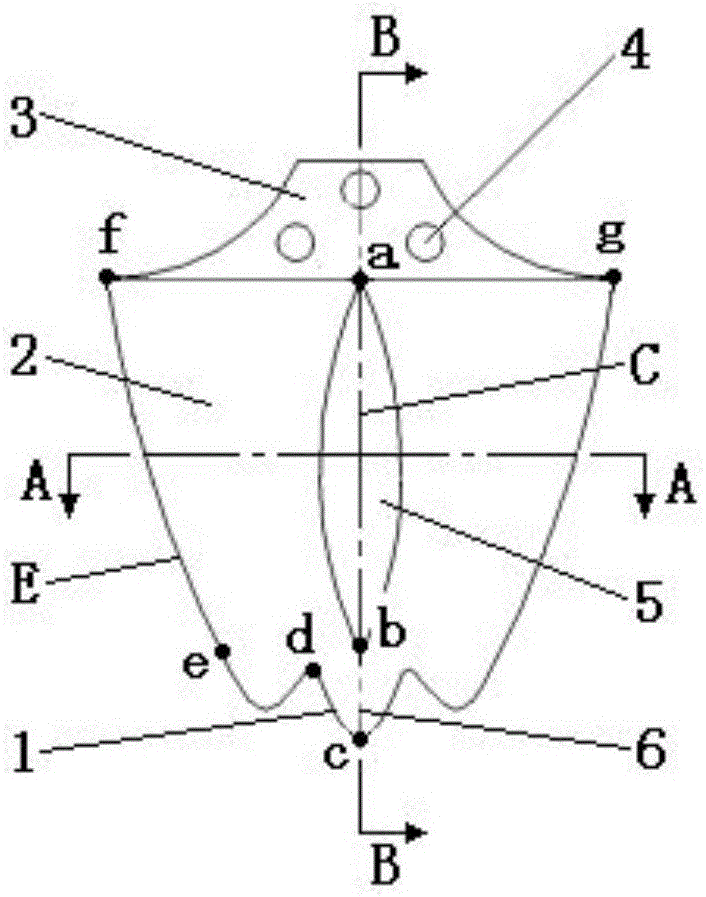

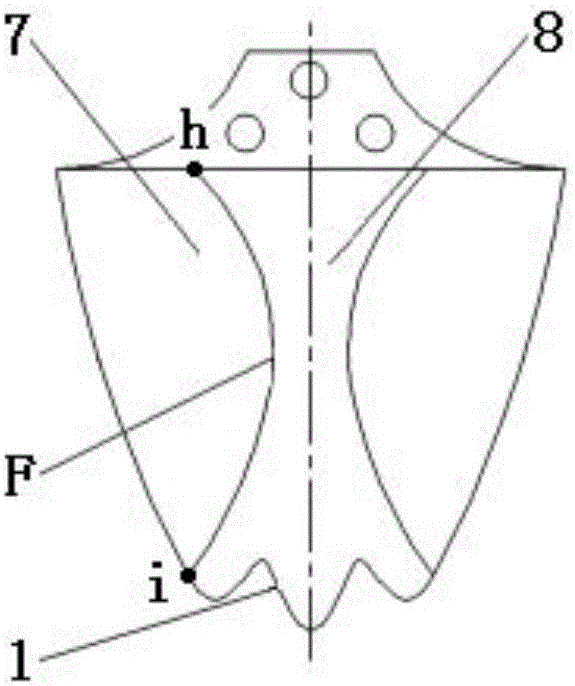

[0025] Such as figure 1 , figure 2 , image 3 The shown bionic drag-reducing potato harvester digging shovel is composed of three shovel teeth 1, soil-contacting shovel surface I2, shovel handle 3, convex surface 5, soil-contacting shovel surface II7 and concave surface 8, wherein the soil-contacting shovel surface Ⅰ2 and the raised surface 5 are located on the front of the excavating shovel, and the raised surface (5) is set in the middle of the soil-contacting shovel surface Ⅰ2, and the point a of the longitudinal section contour line C in the raised surface 5 coincides with the middle point of the straight line f-g at the bottom end of the shovel handle 3 , the cross-sectional contour line G of the convex surface 5 is a j-k curve; the soil-contacting shovel surface Ⅱ7 and the concave surface 8 are located on the opposite side of the excavating shovel, the concave surface 8 is set in the middle of the soil-contacting shovel surface Ⅱ7, and the soil-contacting shovel surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com