Fermenting method for organic solid wastes

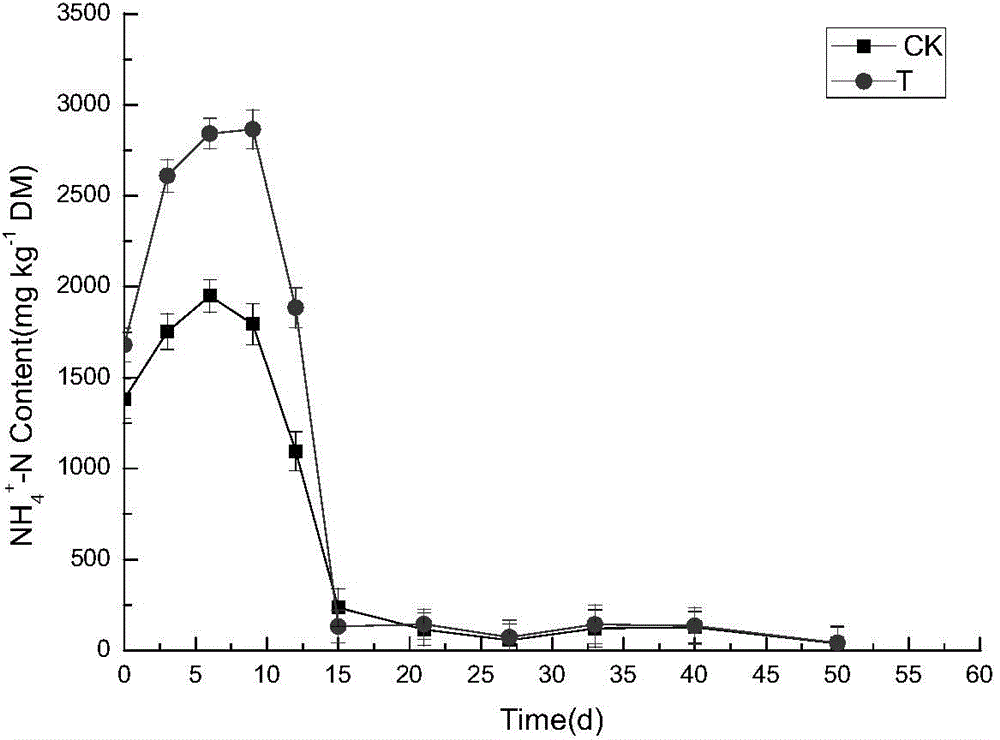

A solid waste and organic solid technology, which is applied in the preparation of organic fertilizers, organic fertilizers, and bio-organic parts treatment, etc., can solve the problems of poor fertilizer efficiency and high pollution of ammonia nitrogen emissions, and achieve better fertilizer efficiency, stable ammonia nitrogen, and improved fertilizer efficiency. The effect of ammonia nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

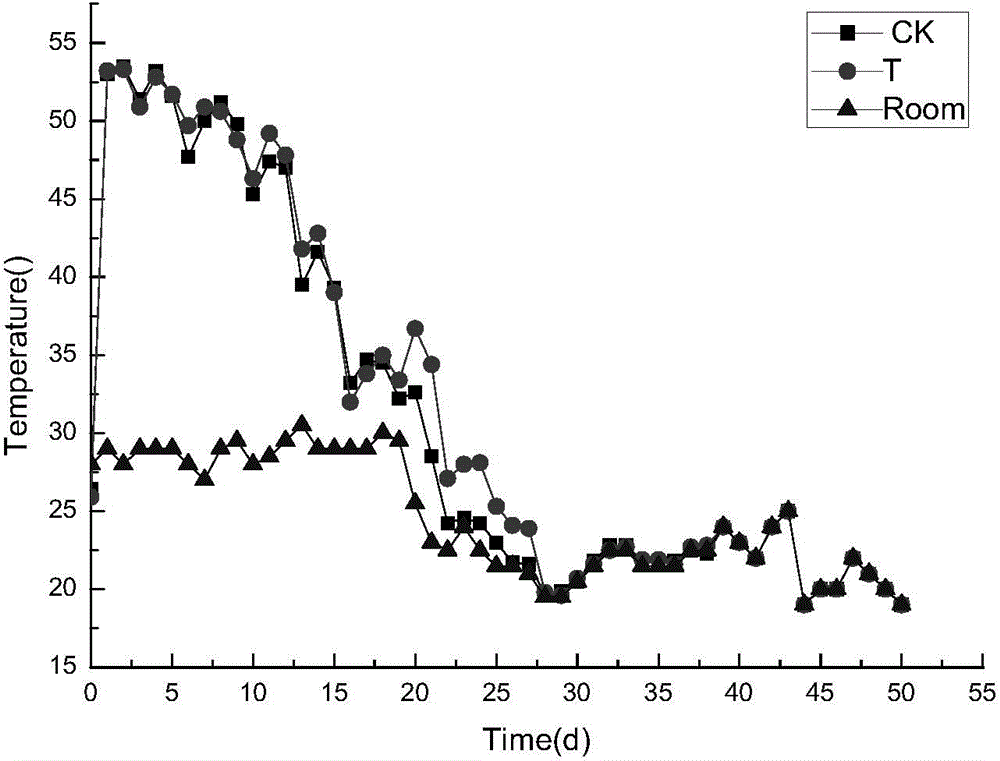

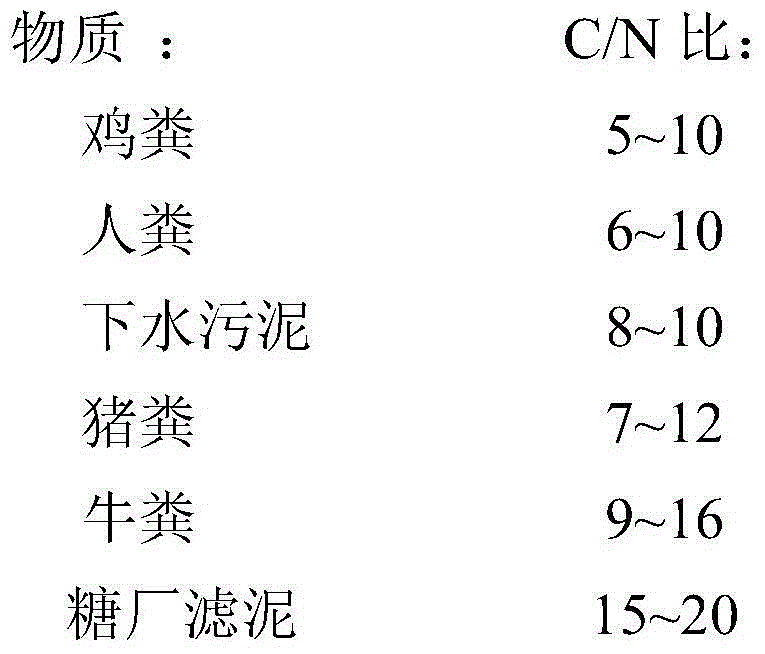

[0029] Take 20kg of bacteria stick residue as raw material, then add 8kg of fresh pig manure and 3kg of fresh chicken manure into a 60L open fermenter, adjust the C / N ratio in the raw material to 20-35:1, and control the moisture content in the raw material 55%, then add 1.6kg of desulfurized gypsum (accounting for 5%) and mix well to form a heap. Fermentation is carried out at room temperature. During the fermentation process, turn the heap or ventilate every 3 days, and ferment for 6 days.

Embodiment 2

[0031] Take 15kg of sugar factory filter mud as raw material, then add 10kg of fresh cow dung, 1kg of sugarcane leaves (crushed to <2cm) and put them into a 60L open fermenter to adjust the C / N ratio of the raw materials to 20-35:1. Control the moisture content in the raw material to 60%, then add 2.6kg of desulfurized gypsum (accounting for 10%) and mix well to form a heap, ferment at room temperature, turn over or ventilate once every 5 days during the fermentation process, It can be fermented for 21 days.

Embodiment 3

[0033] Take 15kg of grass, wood and peat as raw materials, then add 10kg of fresh pig manure, 10kg of fresh chicken manure, 10g of human manure, and 10g of sewage sludge into a 60L open fermentation tank to adjust the C / N ratio of the raw materials to 20-35 : 1, control the moisture content in the raw material to 70%, then add 8.25kg of desulfurized gypsum (accounting for 15%) and fully mix to form a heap, ferment at room temperature, and turn over the heap every 10d in the fermentation process or Ventilate and ferment for 27 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com