Cable twisting-releasing and surface cleaning movable trolley

A technology for surface cleaning and moving vehicles, which is applied in the field of electric power construction to achieve the effect of reducing labor intensity, good effect and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

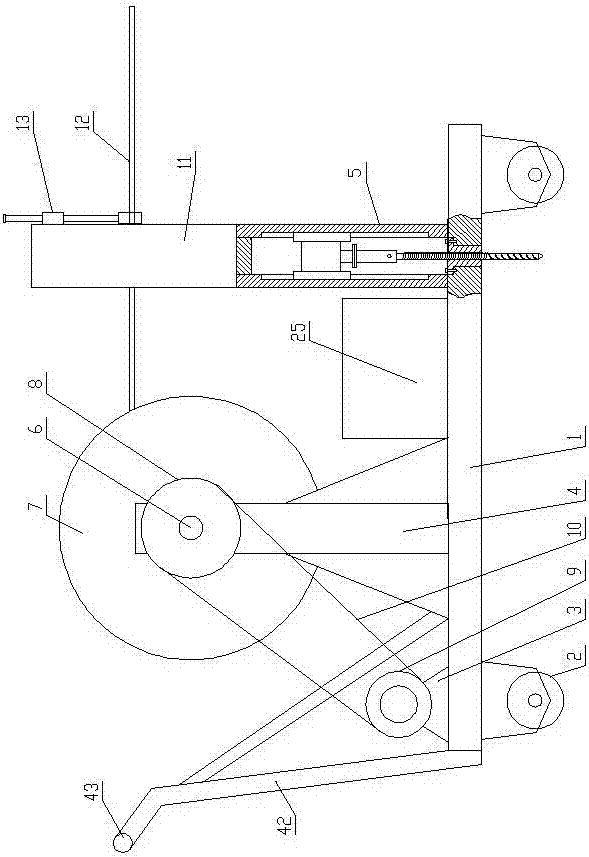

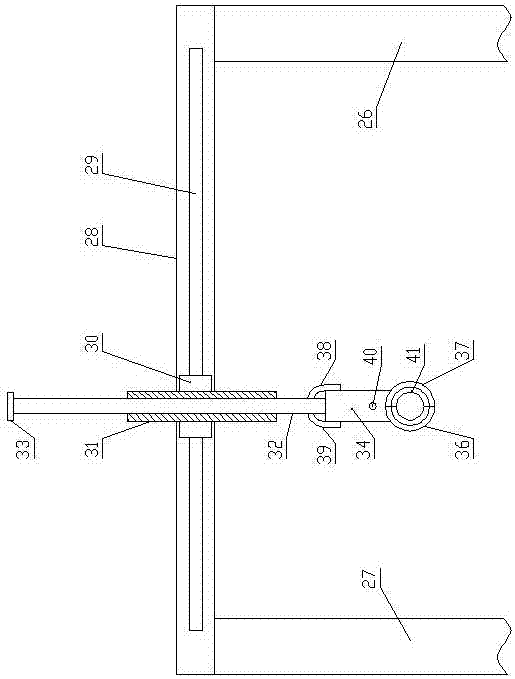

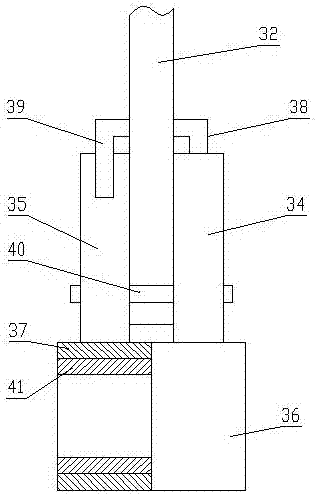

[0024] Such as Figure 1-6 As shown, the cable retractable and surface cleaning mobile vehicle of the present invention includes a horizontal frame 1, and the bottom of the horizontal frame 1 is provided with traveling wheels 2, and the horizontal frame 1 is sequentially provided with a motor reducer 3, a support frame 4 and Positioning the parking mechanism 5, the support frame 4 is rotatably connected with a rotating shaft 6 arranged in the left and right horizontal directions, a cable reel 7 is fixedly arranged on the rotating shaft 6 coaxially, and a driven sprocket 8 is arranged coaxially at one end of the rotating shaft 6, The drive sprocket 9 is coaxially arranged on the power output shaft of the motor reducer 3, and is connected by a chain 10 transmission between the drive sprocket 9 and the driven sprocket 8, and the positioning parking mechanism 5 is symmetrically arranged with two, two A gantry 11 is arranged between the tops of the positioning parking mechanism 5 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com