Combined type ditcher for wheat sowing

A combined trenching and trenching opener technology is applied in the directions of excavation/covering trenches, applications, planting methods, etc., which can solve the problems of difficulty in ensuring the spacing of seed fertilizers, distance of seed damage, and long-distance fertilizer efficiency, and achieve uniform sowing. Problems, consistent spacing between seeds and fertilizers, and the effect of reducing trenching resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

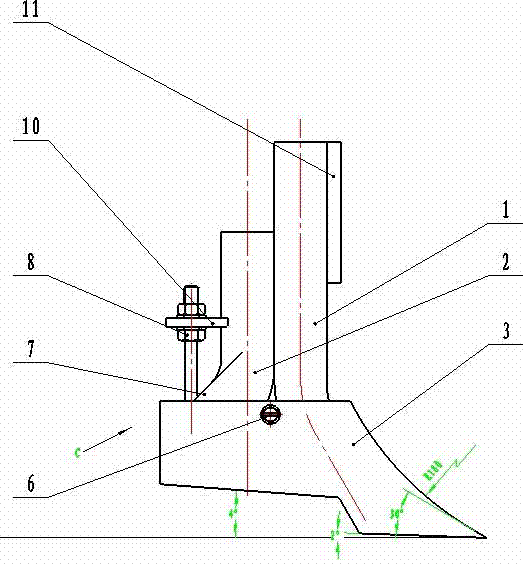

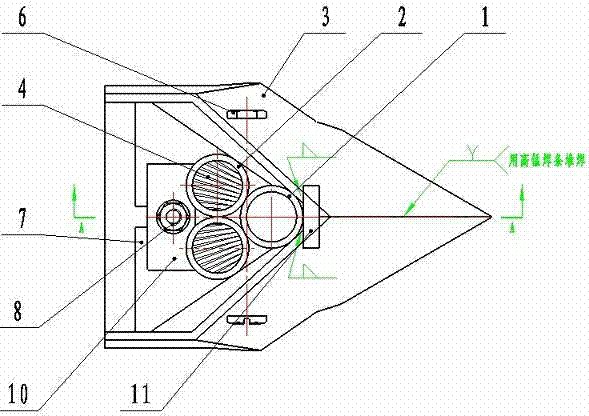

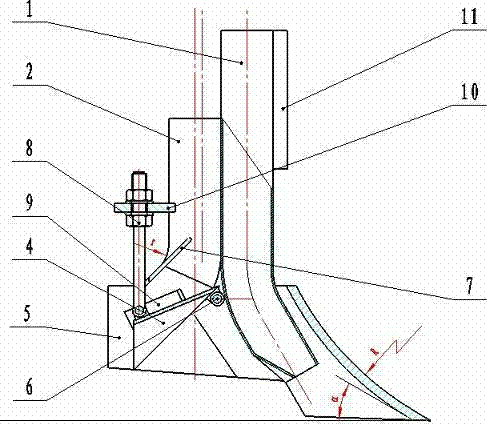

[0020] Such as figure 1 , figure 2 , image 3 , the combined opener for wheat sowing provided by the present invention, the upper part of the fertilizer pipe (1) is welded with the bar-shaped steel plate (8), and the lower part is arc-shaped, located in the front part of the shovel body cavity, and the front part is connected to the shovel body (3 ), the rear part is welded with 2 seed tubes (2) arranged in parallel, the nozzle part of the seed tube (2) is bent backwards, the radius of curvature is 20-30mm, and it is welded with the upper guard plate (7), 2 The upper part of the root seed tube (2) is welded to the strip-shaped mounting plate (10), and the center line of the strip-shaped mounting plate (10) has a circular mounting hole, and the angle adjustment device (8) is installed, and the shovel body (3) is used for ditching operations , the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com