Vibrating type rotary tillage deep scarification integral machine

A vibrating, all-in-one technology, applied in agricultural machinery and implements, shovels, plows, etc., can solve the problems of insufficient subsoiling depth, time-consuming, labor-consuming, etc., and achieve power saving, improved subsoiling depth, and subsoiling quality. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

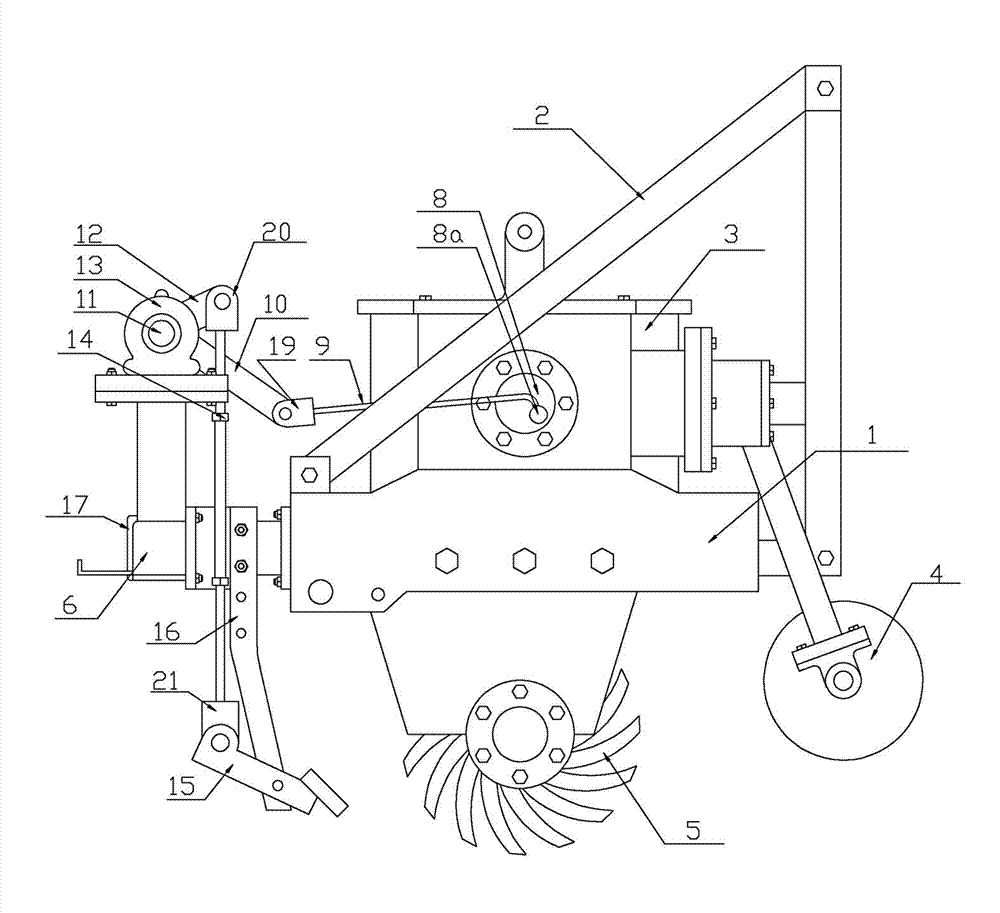

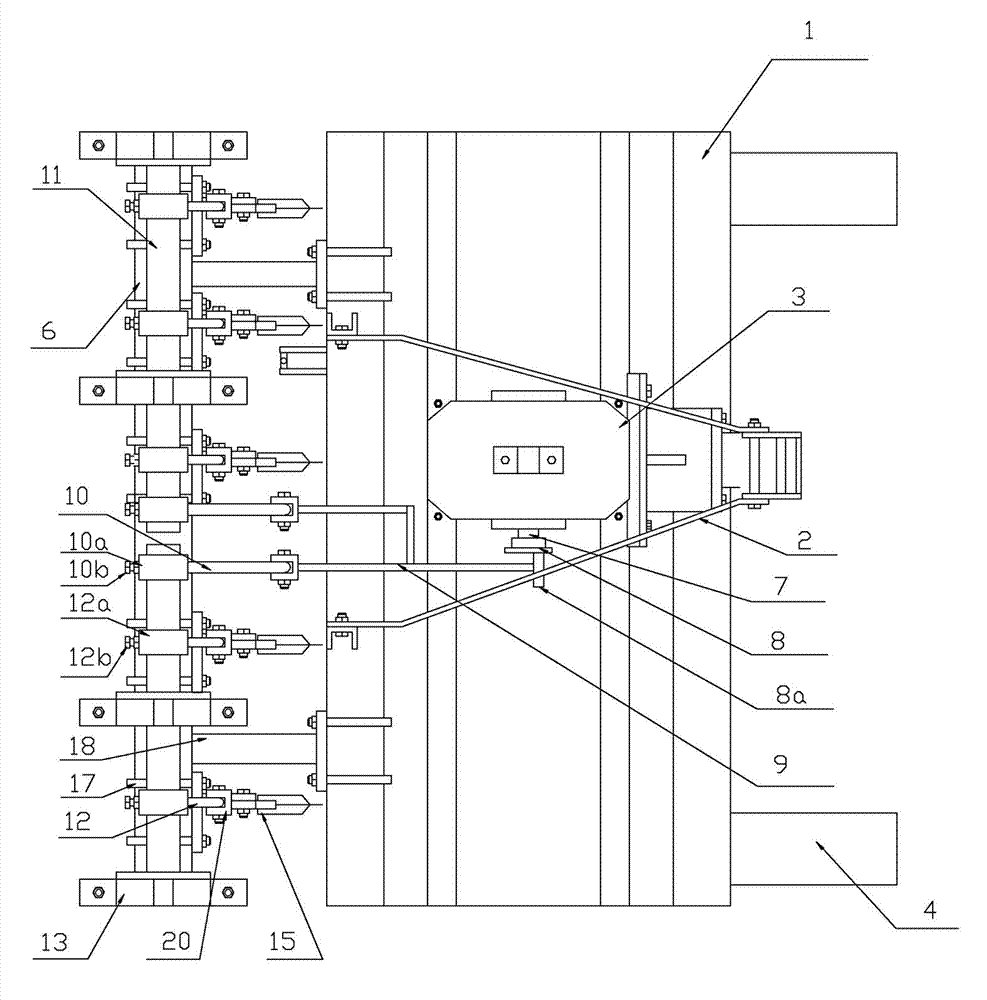

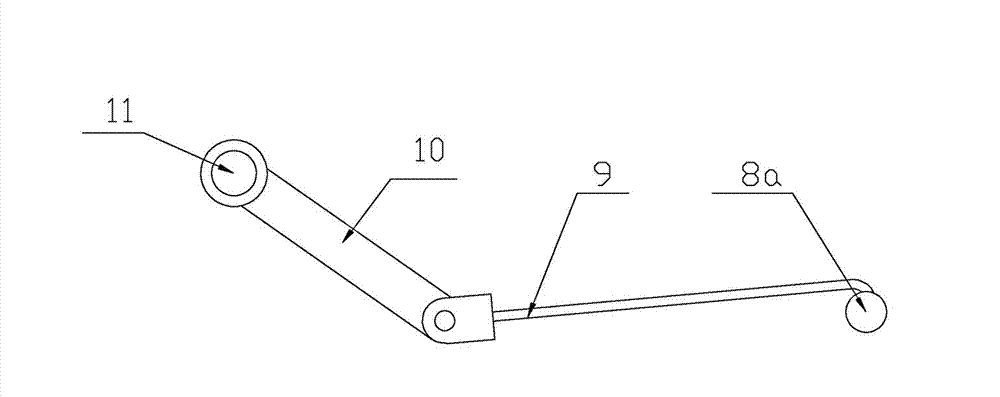

[0020] Such as figure 1 , figure 2 As shown, a traction frame 2 and a gearbox 3 are provided above the rotary tiller frame 1, and a disc pear knife 5 and a depth-limiting wheel 4 are installed below the rotary tiller frame 1, and on the subsoiler beam 6 The shovel arm 16 is fixedly connected by the U-shaped screw 17, the tail of the rotary tiller frame 1 is fixedly connected with the subsoiler beam 6 through the connecting arm 18, and an eccentric wheel 8 is connected to the output shaft 7 of the gearbox 3, and the eccentric wheel 8 The shaft 8a is connected to a connecting rod 9 that swings back and forth with the rotation of the eccentric wheel 8. The open end of the connecting rod 9 is welded with a U-shaped joint 19. The top of the crossbeam 6 of the subsoiler is provided with a rotating shaft 11. The end is supported by the bearing seat 13, and the long transmission arm 10 and the short transmission arm 12 are fixedly arranged on the circumference of the rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com