Adhesive layer-attached retardation film, and elliptical polarizing plate and liquid crystal display device each utilizing same

A retardation film, adhesive layer technology, applied in polarizing elements, layered products, instruments, etc., can solve the problems of adhesive layer peeling, liquid crystal cell paste residue, operability deterioration, etc., to achieve excellent reusability , excellent adhesion, and the effect of realizing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

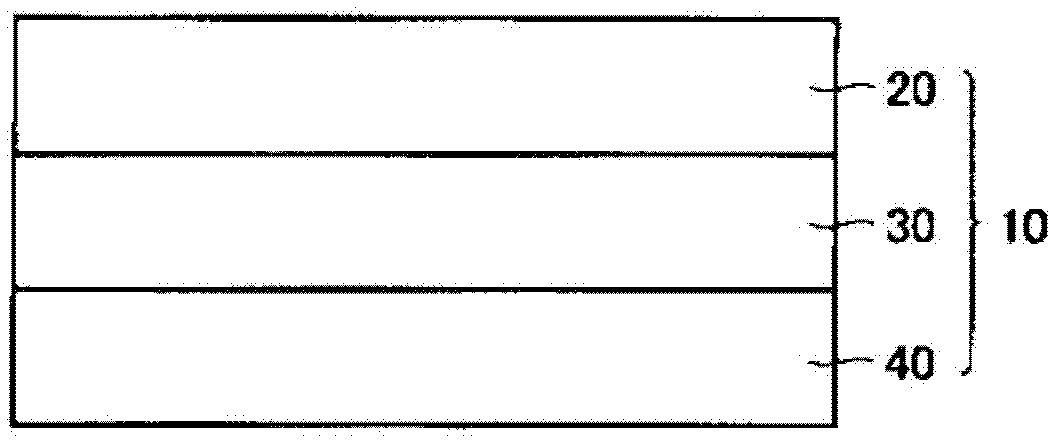

[0152] (Manufacturing example 1: Production of retardation film)

[0153] A propylene / ethylene random copolymer containing about 5% ethylene units ("Sumitomo Noblen W151" manufactured by Sumitomo Chemical Co., Ltd.) was formed into a film to obtain a web film made of a polypropylene-based resin with a thickness of 40 μm. A uniaxial retardation film was obtained by uniaxially stretching this web film in the lateral direction. For this retardation film, the in-plane retardation value R 0 =90nm, retardation value R in the thickness direction th = 45nm, the thickness is 9μm. Then, a self-adhesive surface protection film manufactured by Toray Film Processing Co., Ltd., which is a brand name "Toretec 7332", was bonded to one surface of the retardation film made of a polypropylene resin.

Embodiment 1

[0155] (a) Preparation of coating solution for undercoat layer

[0156] A polyester-based resin (I) having a weight average molecular weight of 35,000 comprising constituent units derived from neopentyl glycol, ethylene glycol, terephthalic acid, and isophthalic acid was dissolved in toluene:methyl ethyl ketone=4: In the mixed solvent of 1, a coating solution for an undercoat layer having a polyester resin (I) concentration of 10% was prepared. The content rate of the structural unit derived from neopentyl glycol, ethylene glycol, terephthalic acid, and isophthalic acid in polyester resin (I) was 1:1:1:1 by molar ratio.

[0157] (b) Formation of undercoat layer for retardation film

[0158] On the surface of the retardation film made of polypropylene resin obtained in Production Example 1, which is opposite to the surface on which the surface protective film was laminated, the cumulative irradiation dose was 15.9 kJ / m 2 Implement corona discharge treatment. Within 5 minutes...

Embodiment 2

[0162] Polyester-based resin (II) having a weight average molecular weight of 33,000 comprising constituent units derived from neopentyl glycol, ethylene glycol, terephthalic acid, isophthalic acid, and 5-sodium sulfoisophthalate was dissolved in Toluene: methyl ethyl ketone = 1:1 mixed solvent, using the thus obtained polyester resin (II) concentration of 10% of the undercoat layer coating liquid, the same as the example 1 An elliptically polarizing plate with an adhesive layer was produced in the same manner. The molar ratio of the constituent units derived from neopentyl glycol, ethylene glycol, terephthalic acid, isophthalic acid, and 5-sodium isophthalic acid in the polyester-based resin (II) was 1:1:1:1:0.005.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com