Plug-in used for test sorter

A technology for testing sorting machines and testing machines, which is applied in sorting and other directions, can solve problems such as contact or design restrictions, and achieve the effect of preventing contact and achieving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

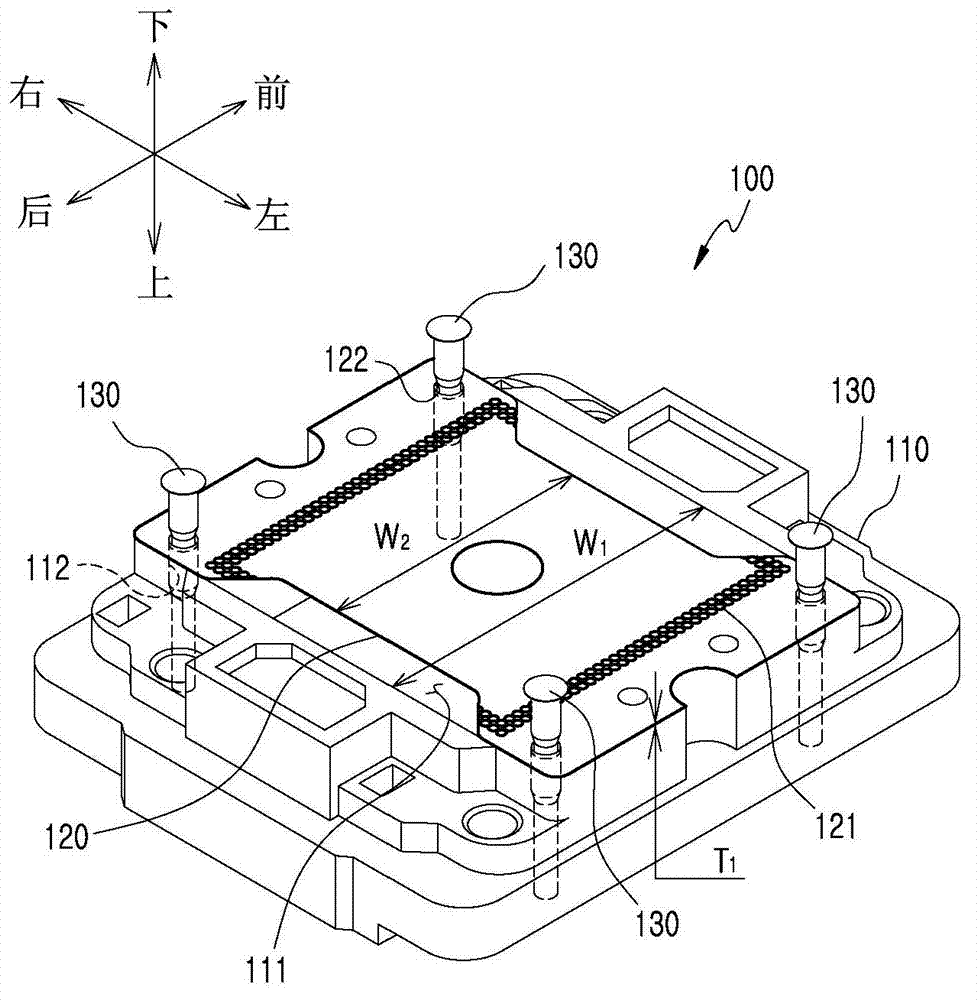

[0043] figure 1 This is a schematic perspective view of a test handler insert (hereinafter simply referred to as insert) 100 according to the first embodiment of the present invention viewed from the lower side.

[0044] Such as figure 1 As shown, the insert 100 according to this embodiment includes a main body 110 , a supporting part 120 , a fixing part 130 and the like.

[0045] An insertion hole 111 and four fixing holes 112 are formed on the main body 110 .

[0046] The insertion hole 111 is used to insert and mount a semiconductor element (not shown), and is formed to open in the vertical direction.

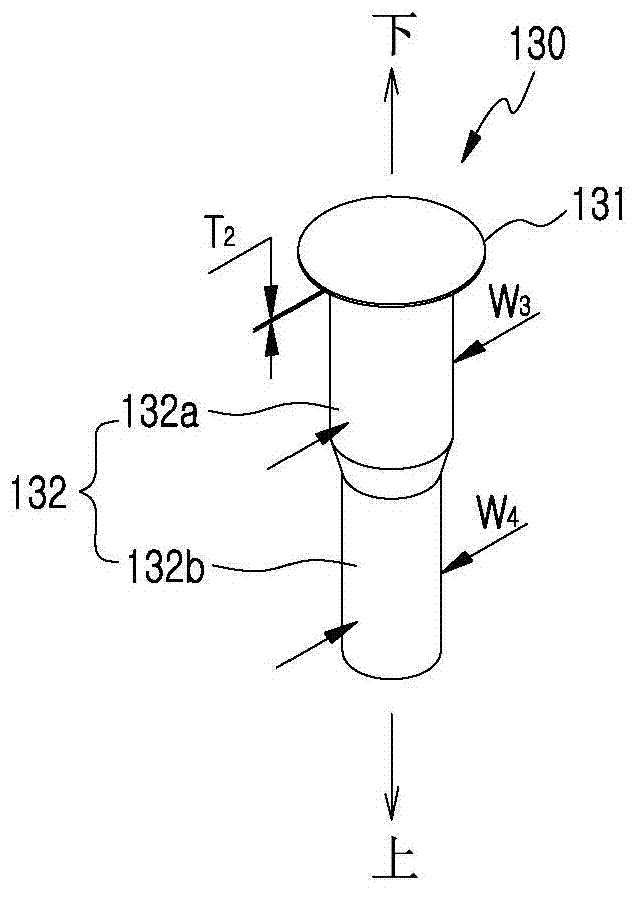

[0047]The four fixing holes 112 are used to fix the support member 120 , as shown by the dotted lines, the four fixing holes 112 not only form an open structure below for inserting the fixing member 130 , but also form an open structure above. Since the fixing hole 112 is open to the outside not only below but also above for inserting the fixing member 130 , the interfere...

no. 2 example

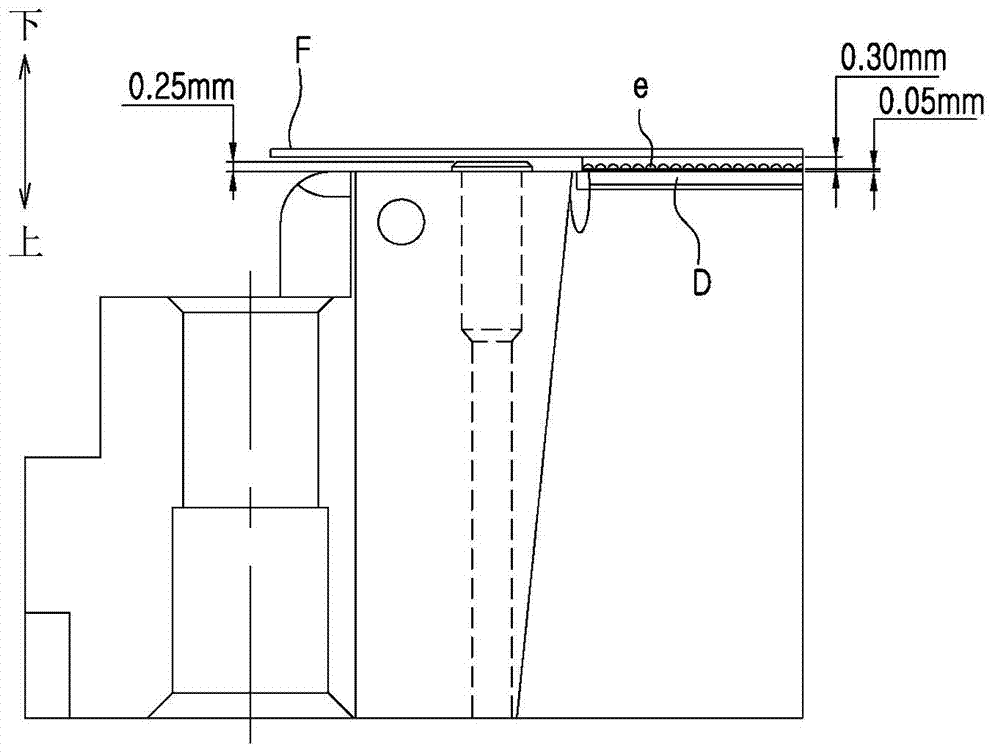

[0060] Figure 4 is a conceptual side view of an insert 400 according to a second embodiment of the present invention.

[0061] In this embodiment, the fixing part 430 and the main body 410 are injection molded into one body. Therefore, when the support member 420 is fixed to the main body 410, as Figure 4 As shown in (a), after inserting the fixing member 430 into the position setting hole (not shown) of the supporting member 420, and then Figure 4 As shown in (b), the pressing part 431 is formed by welding the fixing member 430 . In this case, there is no need to consider the depth of the screwdriver groove or the rigidity of the wrench when rotating, so the minimum thickness (a thickness greater than 0.00mm and less than 0.25mm) that just meets the rigidity conditions required for fixing the support member 420 can be formed. extrusion part 431 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com