Corrosion-resistant hot-rolled ribbed steel bar with yield strength not less than 600Mpa and production method thereof

A hot-rolled ribbed steel bar, yield strength technology, applied in the field of ribbed steel bar and its production, corrosion-resistant hot-rolled ribbed steel bar and its production, to achieve the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

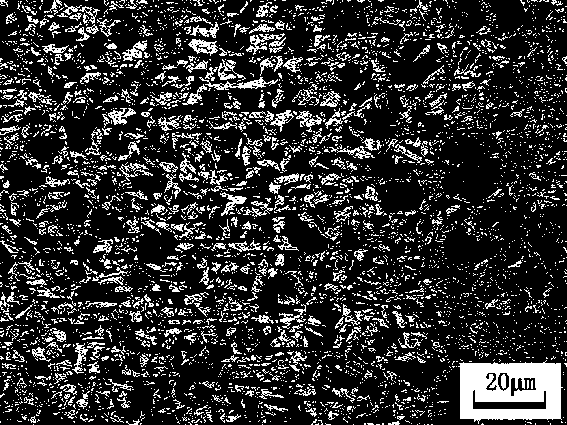

Image

Examples

Embodiment Construction

[0038] The present invention is described in detail below:

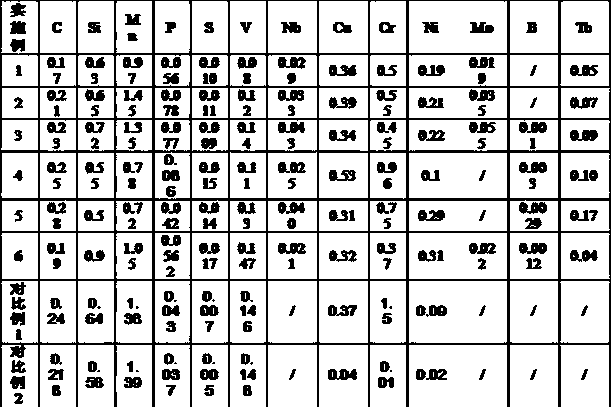

[0039] Table 1 is the value list of each embodiment of the present invention and comparative examples;

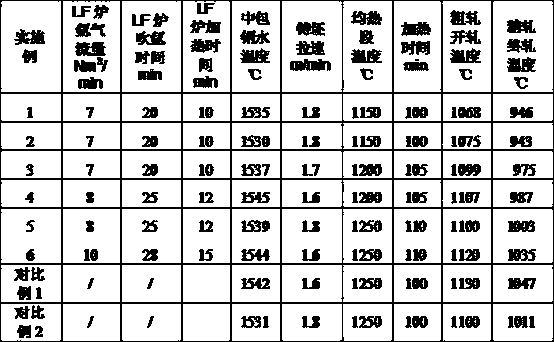

[0040] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

[0041] Table 3 is a list of the performance tests of the various embodiments of the present invention and comparative examples.

[0042] Each embodiment of the present invention is produced according to the following steps:

[0043]1) Desulfurization of molten iron: use magnesium powder desulfurization process, and control the sulfur content of molten iron [S] ≤ 0.010%;

[0044] 2) Converter top-bottom combined blowing: when the amount of tapping reaches 1 / 4 of the total weight of molten steel, add ferrosilicon manganese to molten steel at a rate of 21-24 kg / ton of steel, and add carbonization at a rate of 1.3-1.7 kg / ton of steel Silicon is deoxidized. After deoxidation, 1.8-2.5 kg of ferrova...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com