Composite bi-component polyurethane adhesive capable of resisting 121 DEG C thermophilic digestion as well as preparation method and using method of adhesive

A two-component polyurethane and polyurethane adhesive technology, which is applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problems of inability to withstand high-temperature cooking, unfavorable development of national industries, and high cost. Achieve the effect of wide application, low cost and good polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A component:

[0029] Add 40.5g of isocyanate in the reaction kettle, drop 22g of polyester with a molecular weight of 1500 at 35°C at a rate of 300kg / h, and keep the temperature at 45°C for 3 hours after the addition; add 18gPPG2000 at a rate of 280kg / h at 35°C, After the dropwise addition, continue the reaction at 35°C for 2.5 hours to obtain component A;

[0030] B component:

[0031] Add 1 mol of castor oil, 1 mol of ethylene glycol, 1.5 mol of serotonin, and 0.5 mol of glycerin into the reactor, and alcoholyze at 220°C for 3 hours under the catalysis of 100ppm lithium hydroxide, then add 3 mol of sebacic acid and esterify at 230°C for 14 hours until the acid value is less than 5mgkoh / g, and the hydroxyl value is 130mgkoh / g, then cooled to 100°C and released for packaging.

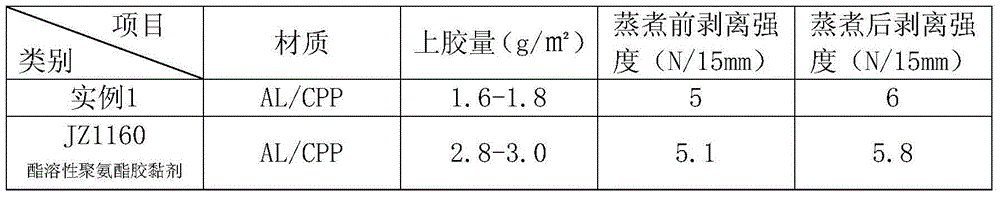

[0032] According to the mass ratio of component A: component B = 100:62, it is coated on the bonded material by a solvent-free laminating machine, and cured at 45°C for 68 hours to obtain a tw...

Embodiment 2

[0034] A component:

[0035] Add 19g of isocyanate in the reaction kettle, add dropwise 21g of polyester with a molecular weight of 1500 at 40°C at a rate of 310kg / h, and keep the temperature at 45°C for 4 hours after the addition; add 17.14gPPG2000 dropwise at 40°C at a rate of 280kg / h, Continue the reaction at 40°C for 2.5h after the dropwise addition, continue to add 36gPPG1000 dropwise at a rate of 280kg / h, keep the temperature at 50°C for 3h after the dropwise addition, cool down to 45°C and discharge.

[0036] Component B: Add 1 mol castor oil, 1 mol ethylene glycol, 1.5 mol new fenugreek, and 0.5 mol glycerin to the reaction kettle, and alcoholyze at 240°C for 2.5 hours under the catalysis of 100 ppm lithium hydroxide, then add 2 mol of sebacic acid, 1 mol For terephthalic acid, esterify at 220°C for about 15 hours until the acid value is less than 5 mgkoh / g, and the hydroxyl value is 130 mgkoh / g, then cooled to 100°C for discharge and packaging.

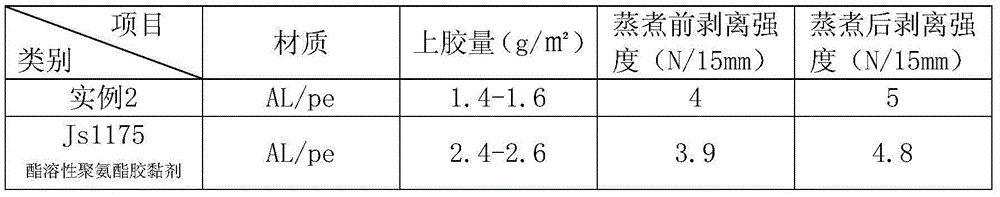

[0037] According to ...

Embodiment 3

[0039] A component:

[0040] Add 40.5g of isocyanate in the reaction kettle, drop 22g of polyester with a molecular weight of 1500 at 45°C, the drop rate is 295kg / h, and keep the temperature at 45°C for 4 hours after the addition; add 18gPPG2000 dropwise at 45°C, and the drop rate is 280kg / h h, continue the reaction at 45°C for 2.5h after the dropwise addition, and obtain component A;

[0041] Component B: Add 1 mol castor oil, 1 mol ethylene glycol, 1.5 mol new fenugreek, and 0.5 mol glycerin to the reaction kettle, and alcoholyze at 240°C for 3.5 hours under the catalysis of 100 ppm lithium hydroxide, then add 3 mol of sebacic acid, 1 mol of Phthalic acid, esterified at 230°C for about 16 hours until the acid value is less than 5mgkoh / g, and the hydroxyl value is 130mgkoh / g, cooled to 100°C for discharge and packaging.

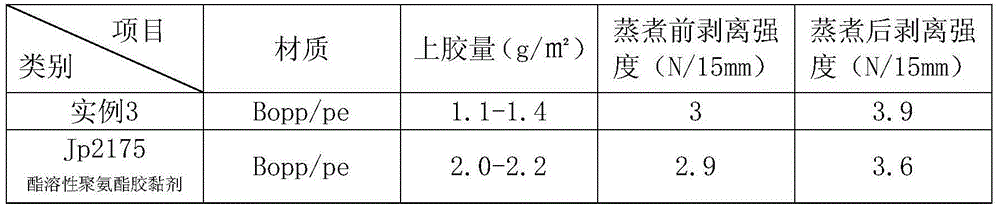

[0042] Mix according to the mass ratio of component A: component B = 100:85, then apply it to the bonded material through a solvent-free laminating machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com