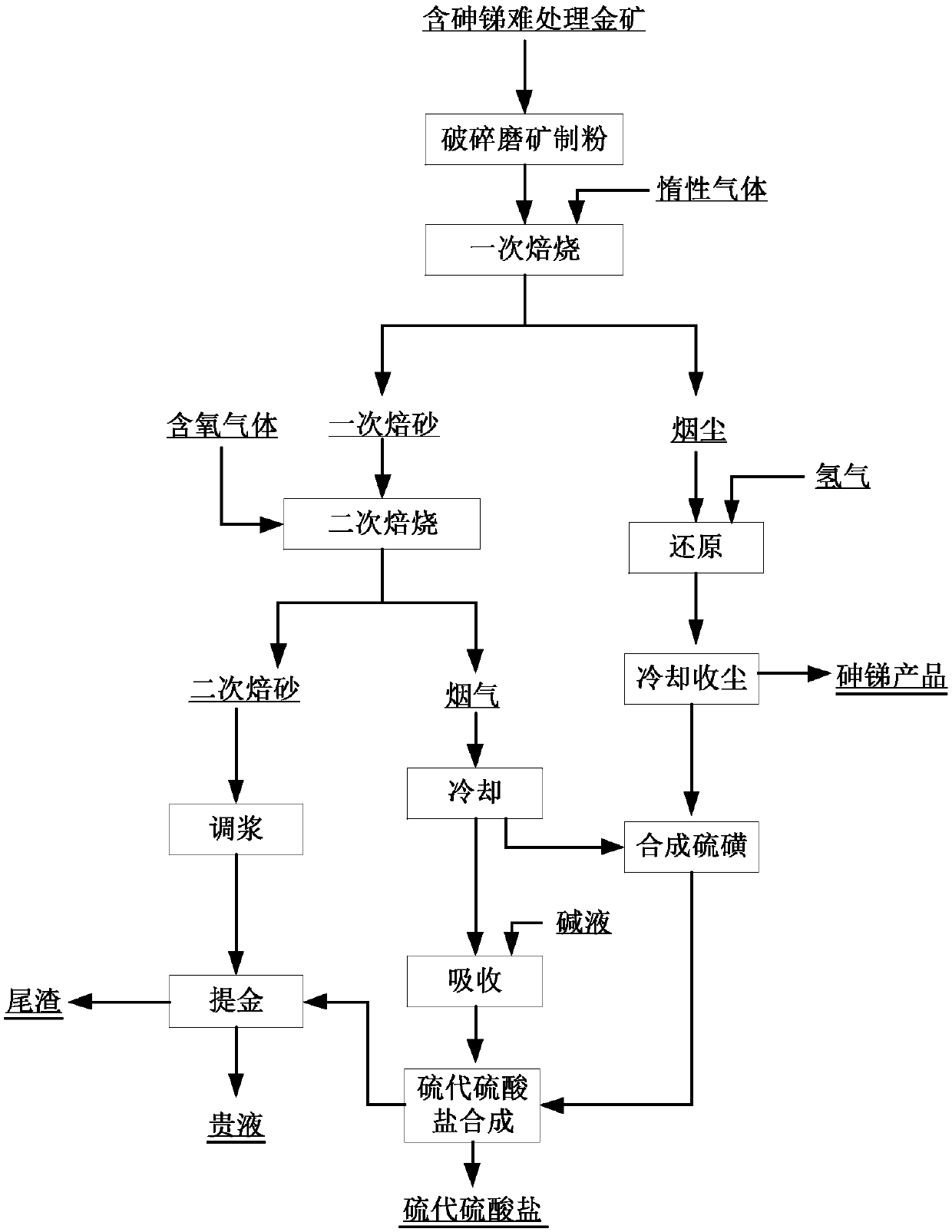

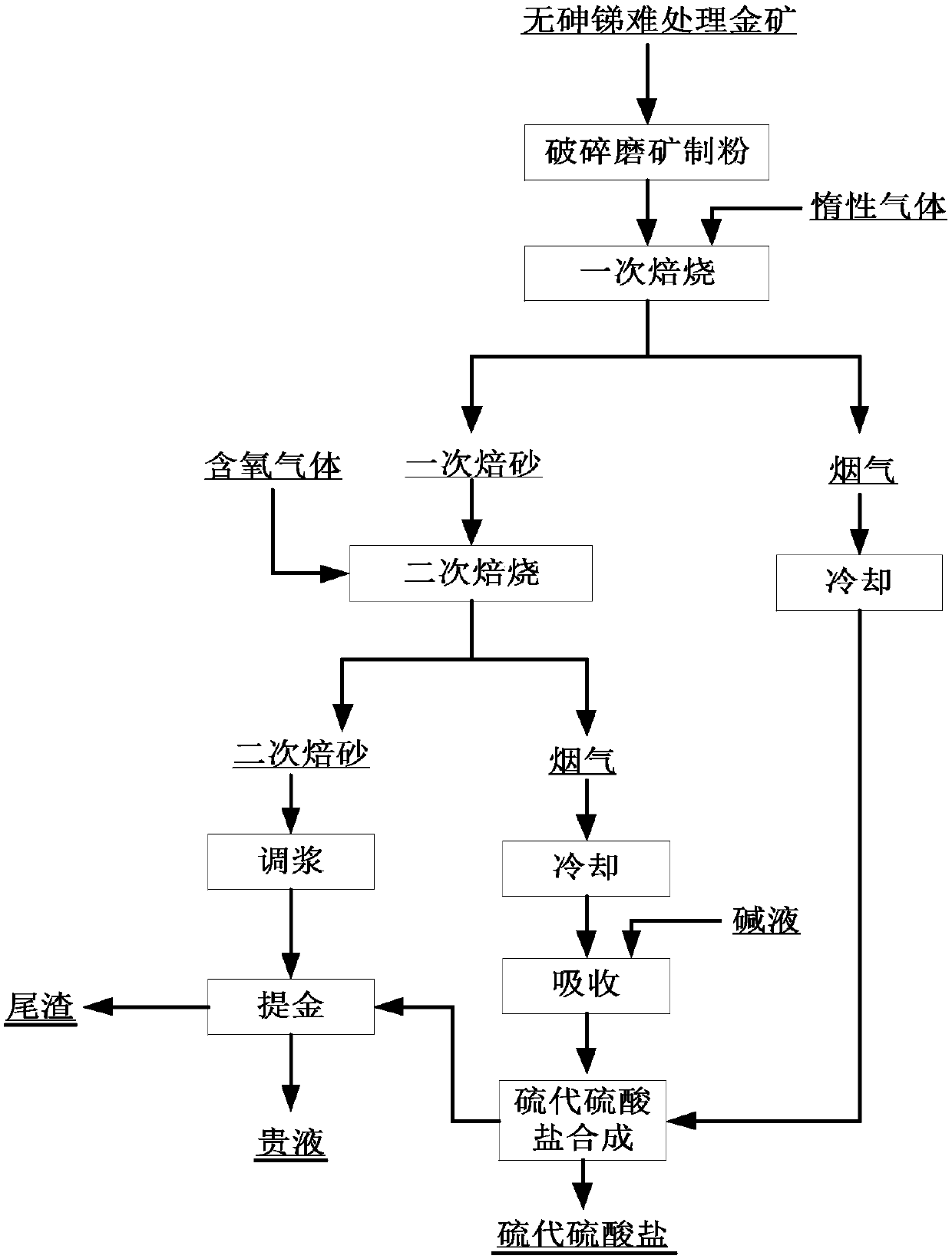

Technology for preparing thiosulfate on site and extracting gold from refractory gold ore

A technology for thiosulfate and refractory gold ore, which is applied in the direction of thiosulfate/dithionite/polythionate, etc., which can solve the problems of low antimony removal rate, high design and material requirements, and recycling Difficulties and other problems, to achieve the effect of reducing production costs and environmental pressure, significant economic effects, and easy separation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0148] Example 1 selects a refractory gold mine in Gansu, its composition is gold 46.80g / t, iron 21.91%, sulfur 30.63%, arsenic 3.26%, antimony 4.52%. Take 100g of the refractory gold ore to be crushed and milled to make powder. The powder with a particle size of less than 0.074mm accounts for 50% of the total mass of all powders. Put it into a corundum crucible and put it in a closed heating furnace. The heating furnace is heated by electricity. Nitrogen is used for one-stage roasting, the roasting temperature is controlled at 950°C, and the roasting time is 0.5h. After roasting, primary calcined sand and flue gas A are formed. Put the primary calcined sand in another heating furnace, pass air into it and use microwave heating for secondary roasting, the roasting temperature is 550°C, and the roasting time is 4h, and the roasting will form the secondary calcined sand and gas B. Lower the temperature of gas A to 450°C, mix and react with hydrogen (the molar ratio of gas A to h...

Embodiment 2

[0151] Example 2 selects a refractory gold mine in Anhui, and its composition is 55.8g / t of gold, 21.7% of iron, 20.7% of sulfur, 7.23% of arsenic, and 4.2% of antimony. Take 100g of the refractory gold ore to be crushed and milled into powder. The powder with a particle size of less than 0.074mm accounts for 95% of the total mass of all powders. Put it into a corundum crucible and put it into a closed heating furnace. The heating furnace is heated by hot air. Argon is used for roasting, the roasting temperature is controlled at 650 ° C, and the roasting time is 4 hours. After roasting, a calcined sand and flue gas A are formed. Put the primary calcined sand in another heating furnace, feed a mixed gas with an oxygen content of 10%, and use electric heating for secondary roasting. The roasting temperature is 750°C, and the roasting time is 0.5h. The roasting forms the secondary calcined sand and gas B. . Lower the temperature of gas A to 650°C, mix and react with hydrogen (th...

Embodiment 3

[0154] Example 3 selects a refractory gold mine in Liaoning, and its composition is 35.65g / t of gold, 22.57% of iron, 27.98% of sulfur, and no arsenic and antimony. Take 100g of the refractory gold ore to be crushed and milled into powder. The powder with a particle size of less than 0.074mm accounts for 75% of the total mass of all powders. Put it into a corundum crucible and put it into a closed heating furnace. The heating furnace is heated by electricity. Nitrogen is used for roasting, the roasting temperature is controlled at 700°C, and the roasting time is 2 hours. After roasting, a calcined sand and flue gas A are formed. Put the primary calcined sand in another heating furnace, feed a mixed gas with an oxygen content of 65%, and use electric heating for secondary roasting. The roasting temperature is 650°C, and the roasting time is 2 hours. The roasting forms the secondary calcined sand and gas B. After the gas B is cooled to below 100°C, it is fully absorbed with milk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com