Automatic measurement equipment for profile and position of logo mounting hole

A technology for automatic measurement and installation of holes, applied to measuring devices, optical devices, instruments, etc., can solve the problems that the optical three-coordinate measuring instrument is not suitable, is not suitable for ordinary production workshops, and cannot meet the needs of rapid production. Suitable for batch use, reducing cost pressure, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

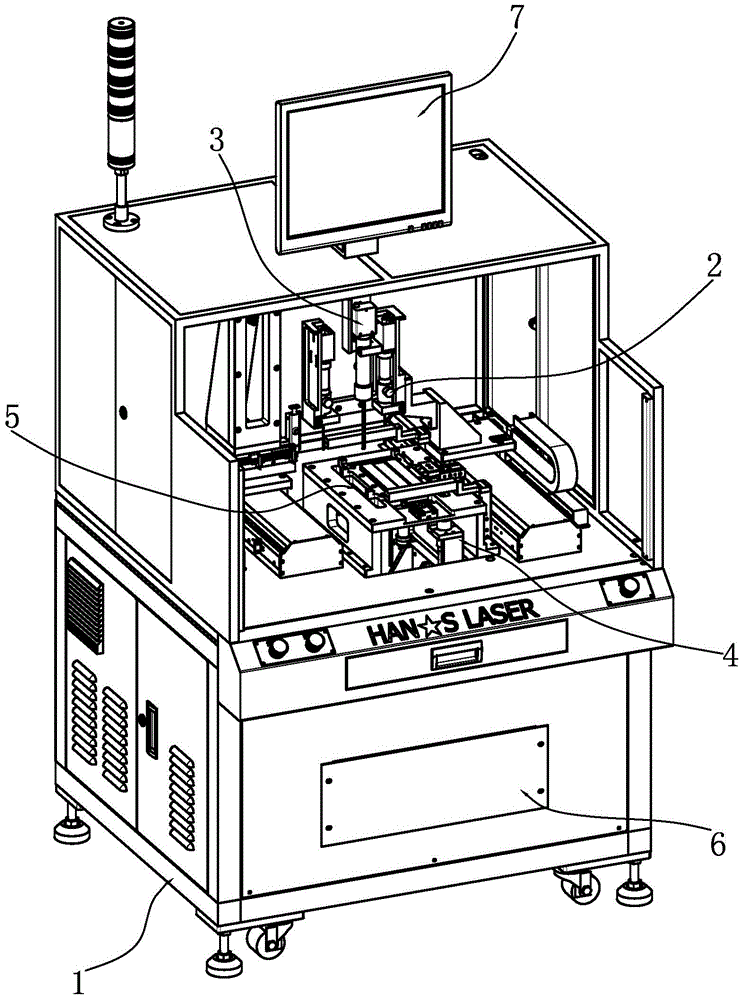

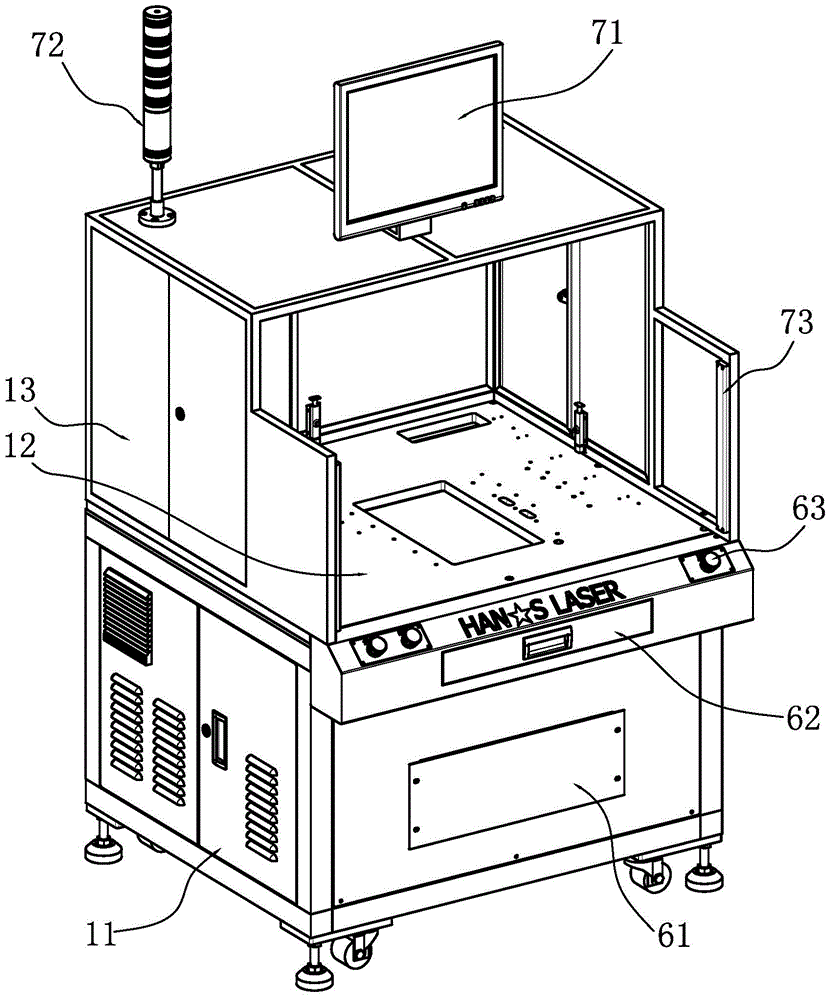

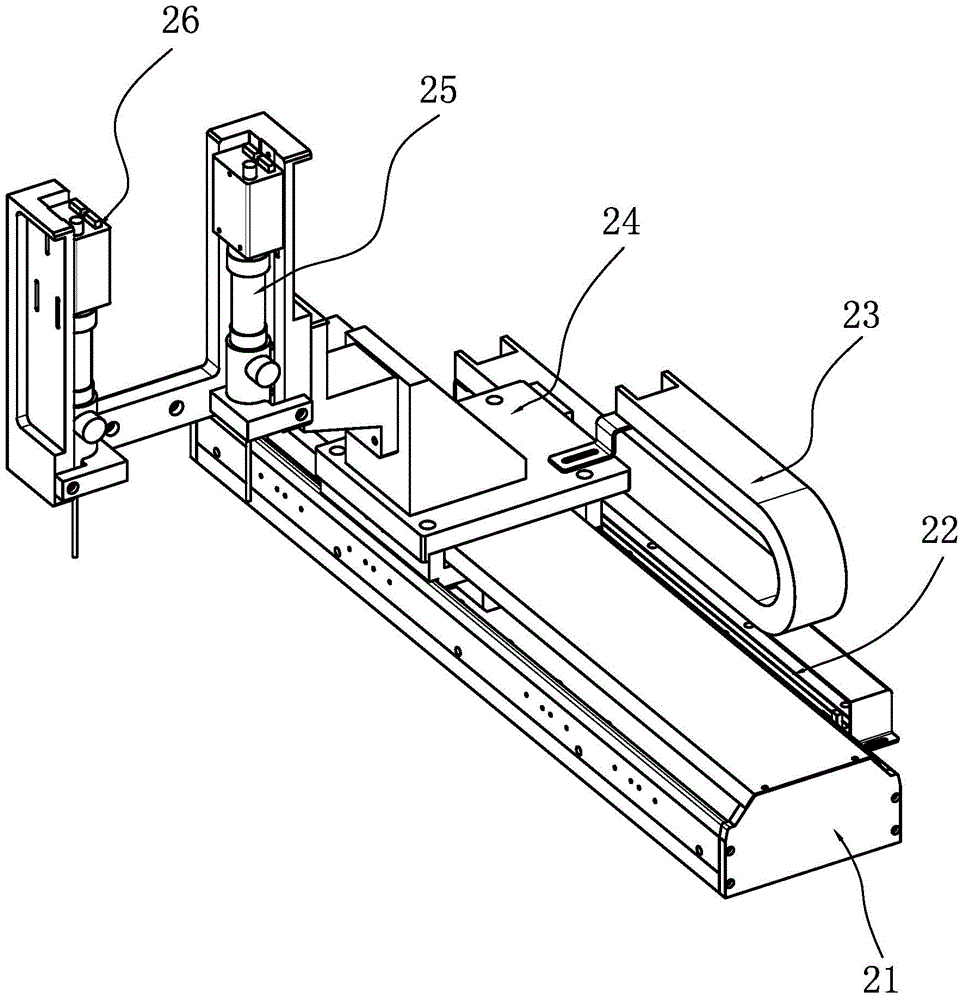

[0024] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

[0025] The present invention proposes an automatic measurement device for the profile and position of the installation hole of the mark, which uses multiple sets of precision servo motion platforms equipped with grating rulers to drive multiple industrial cameras equipped with customized light sources to take pictures, and conduct data analysis through customized software , so as to achieve high-precision and high-efficiency non-contact measurement.

[0026] The present invention adopts the industrial computer as the core control unit of the equipment, and controls the execution unit through compatible motion control cards, I / O cards, image acquisition cards, etc., such as platform movement, light source on and off, camera photography, etc.; The precision servo motion platform, through the real-time feedback signal of the grating ruler, es...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com