Patents

Literature

36results about How to "Meet the needs of rapid production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

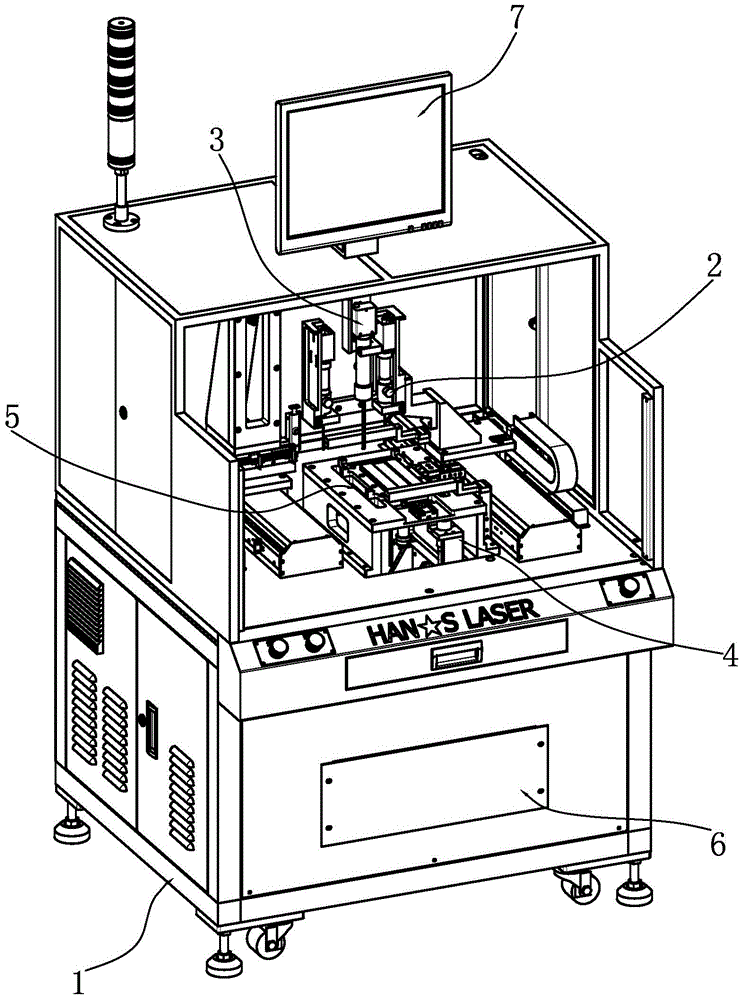

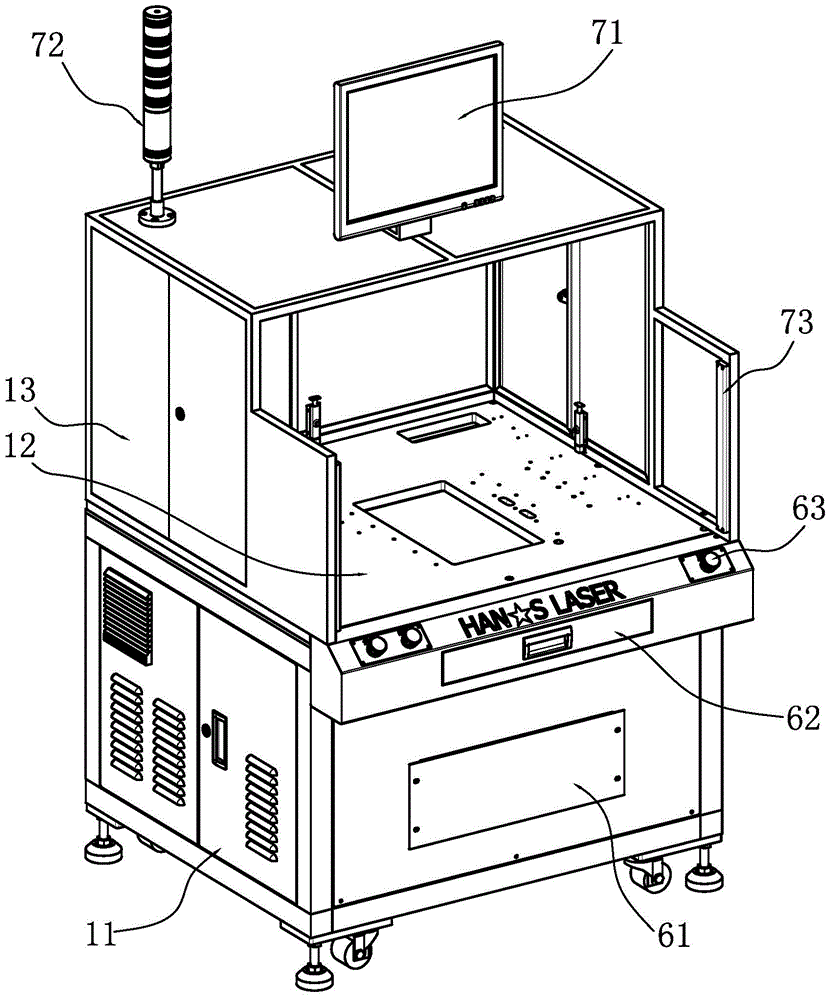

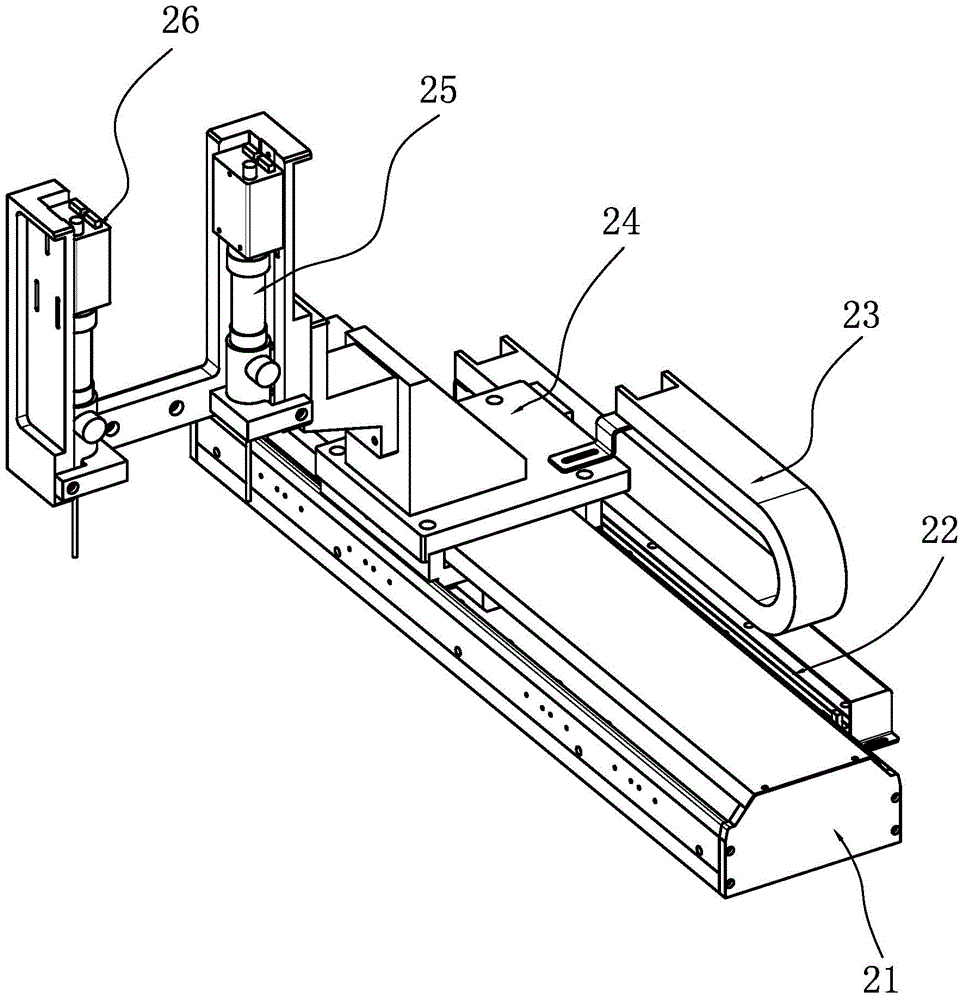

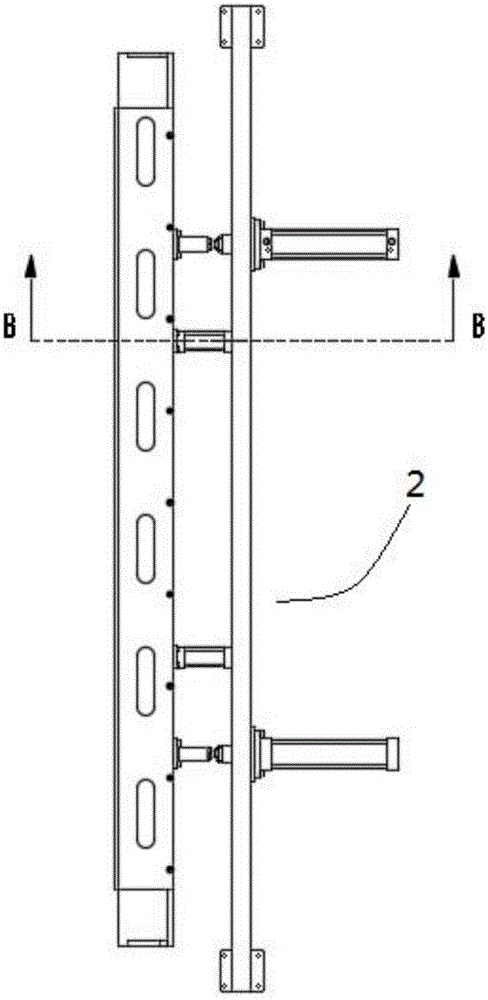

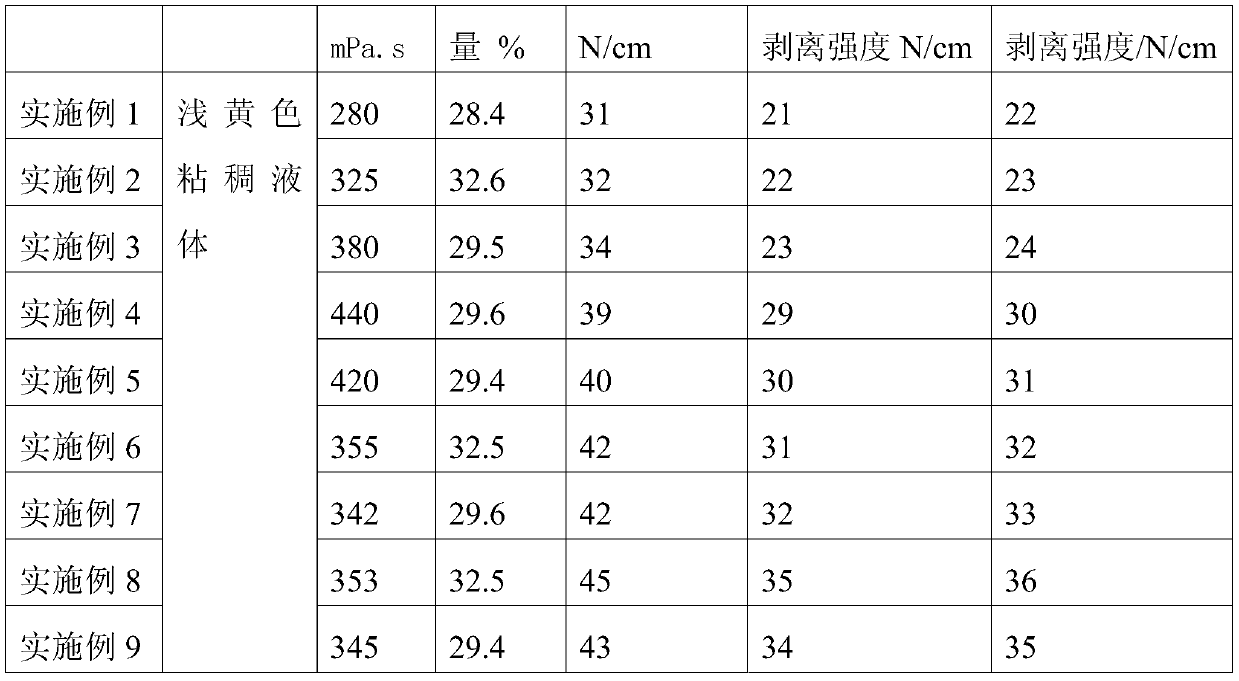

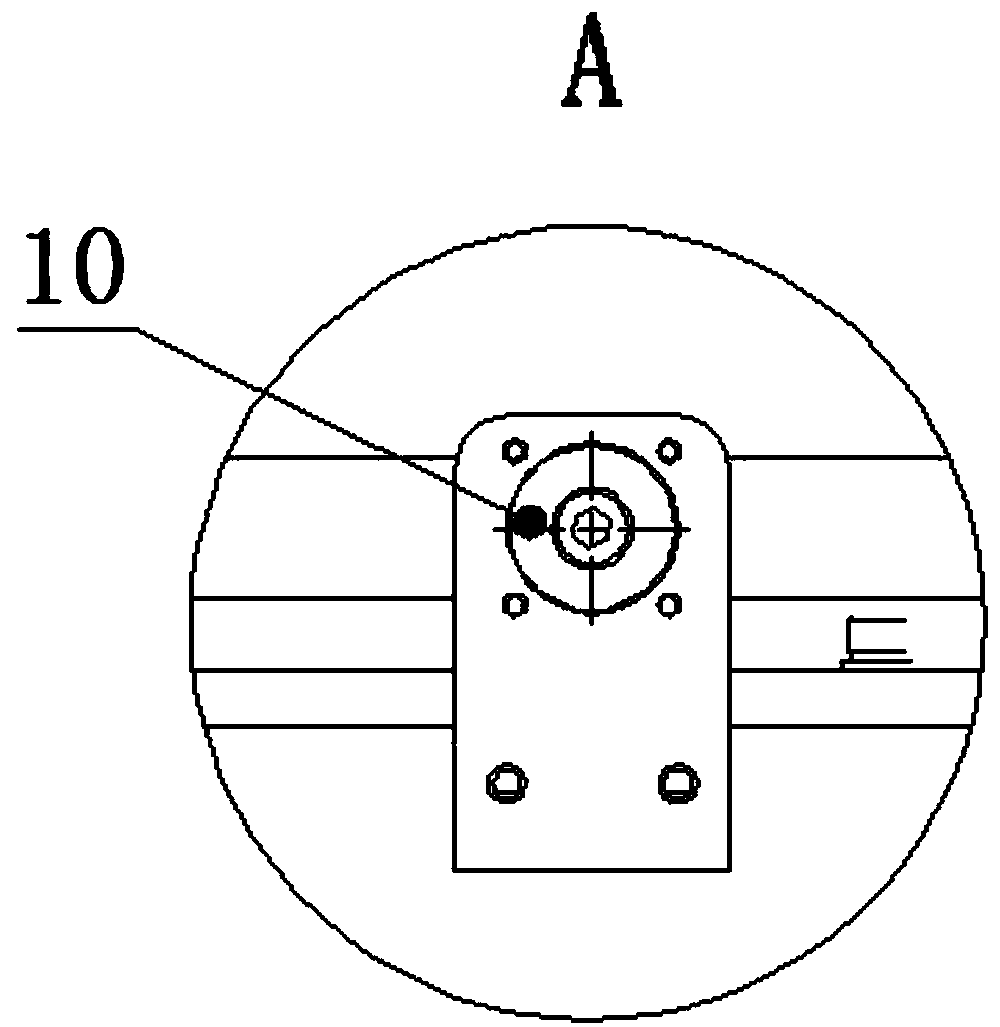

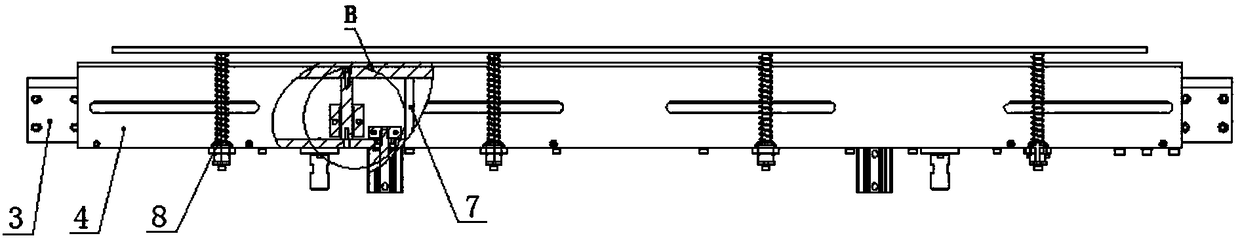

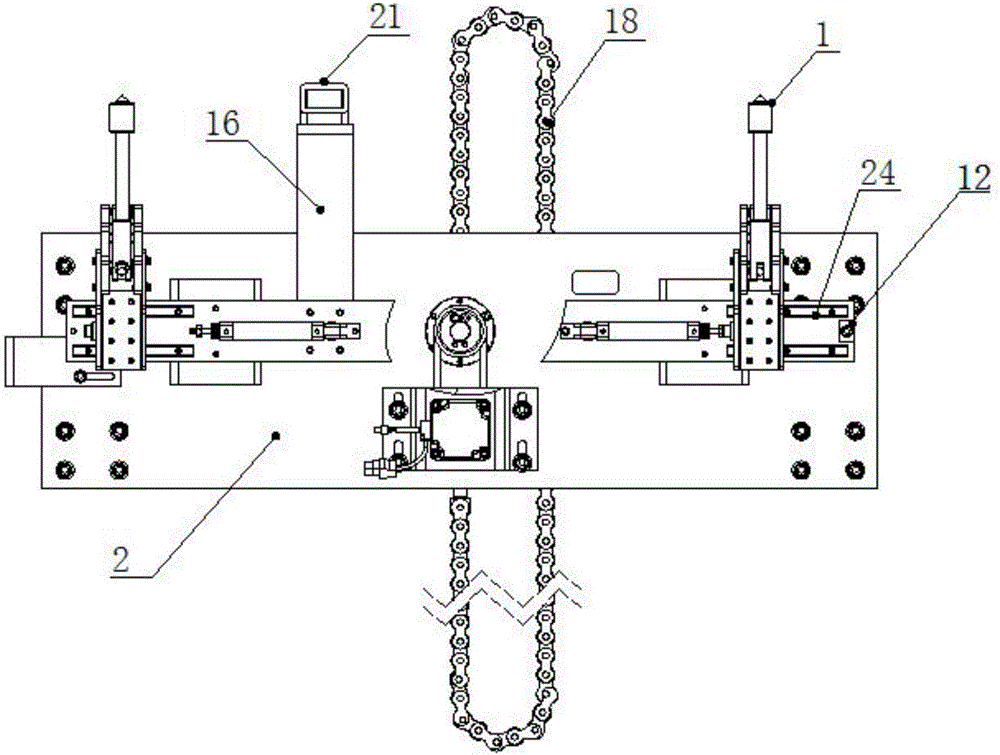

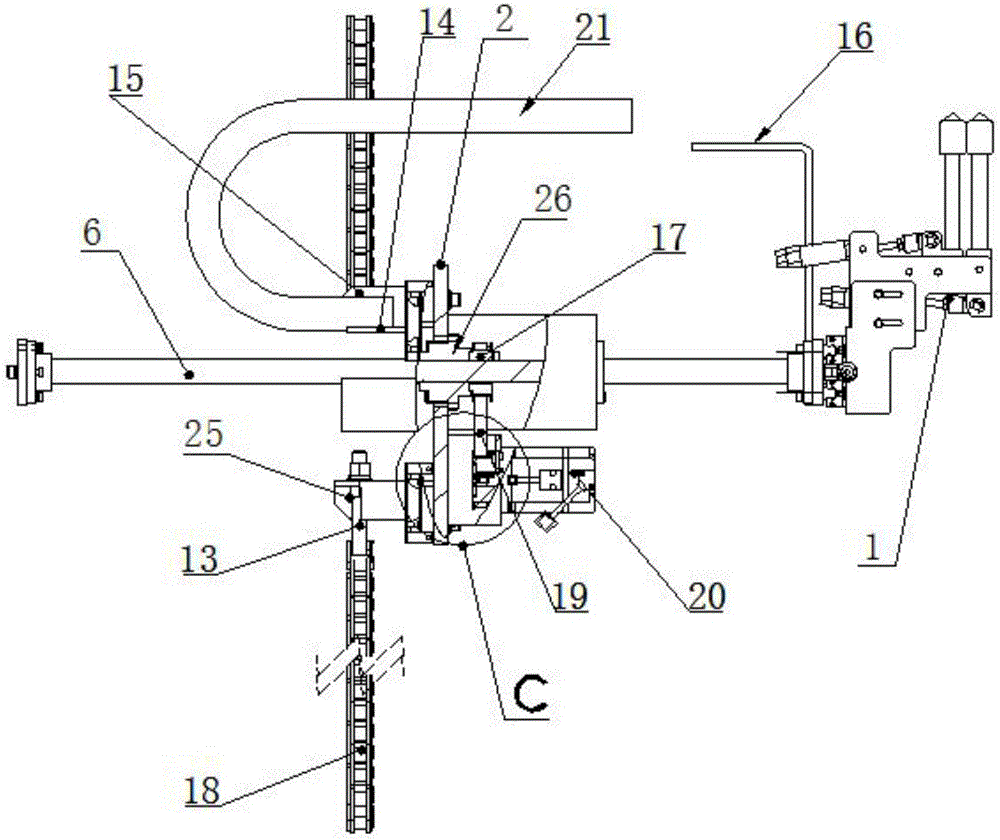

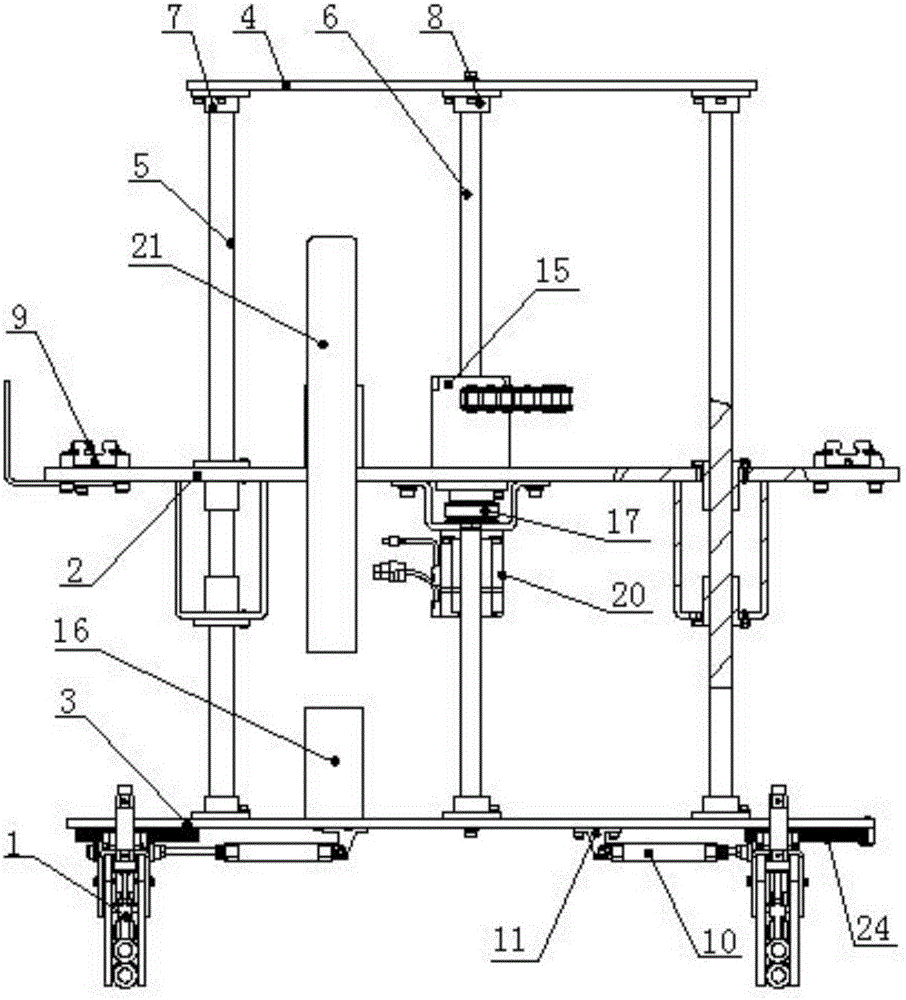

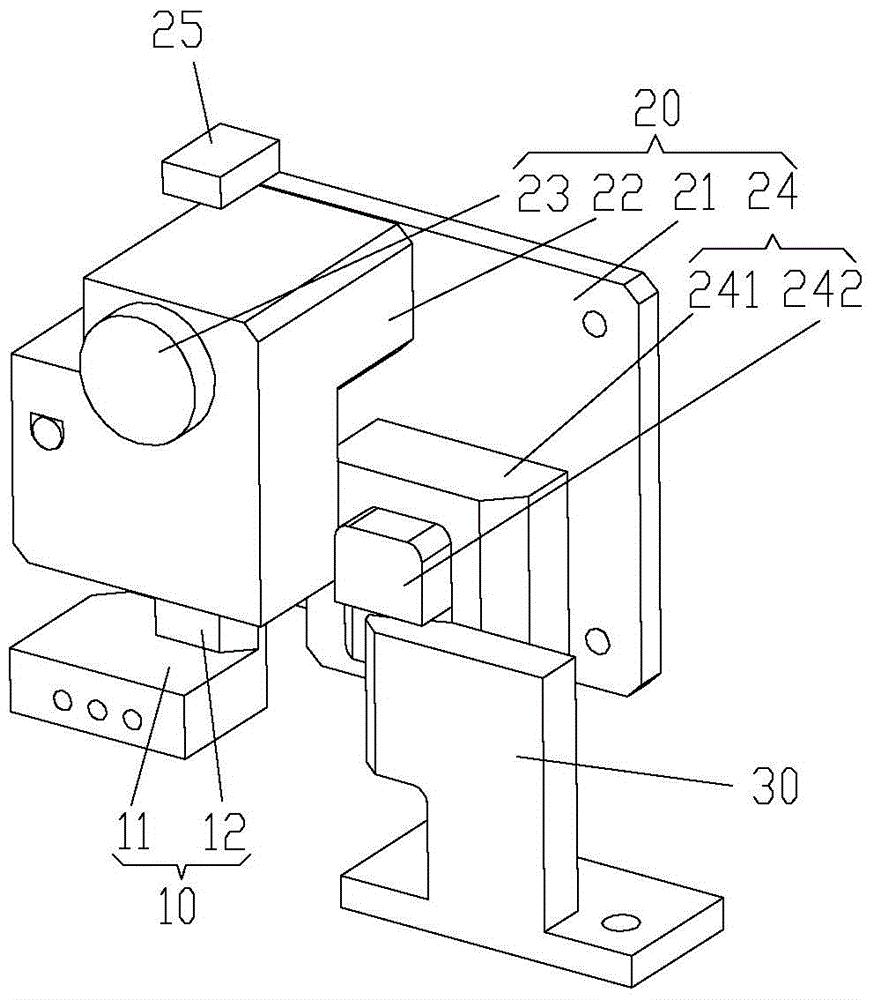

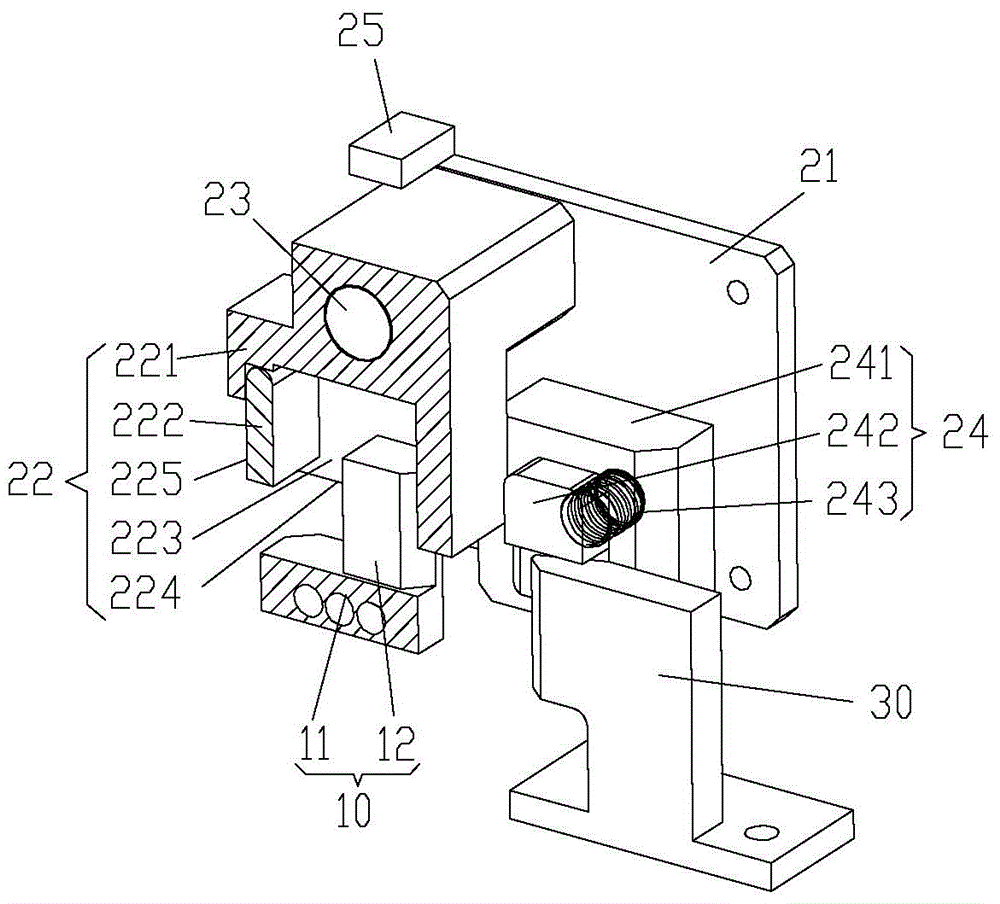

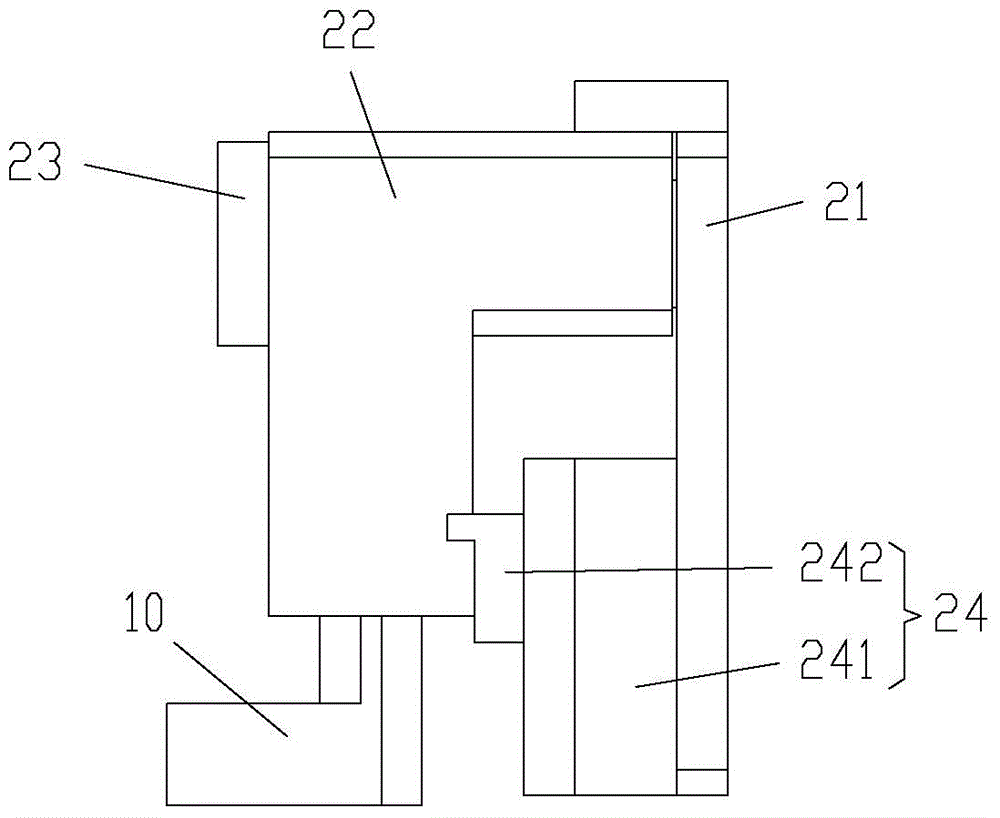

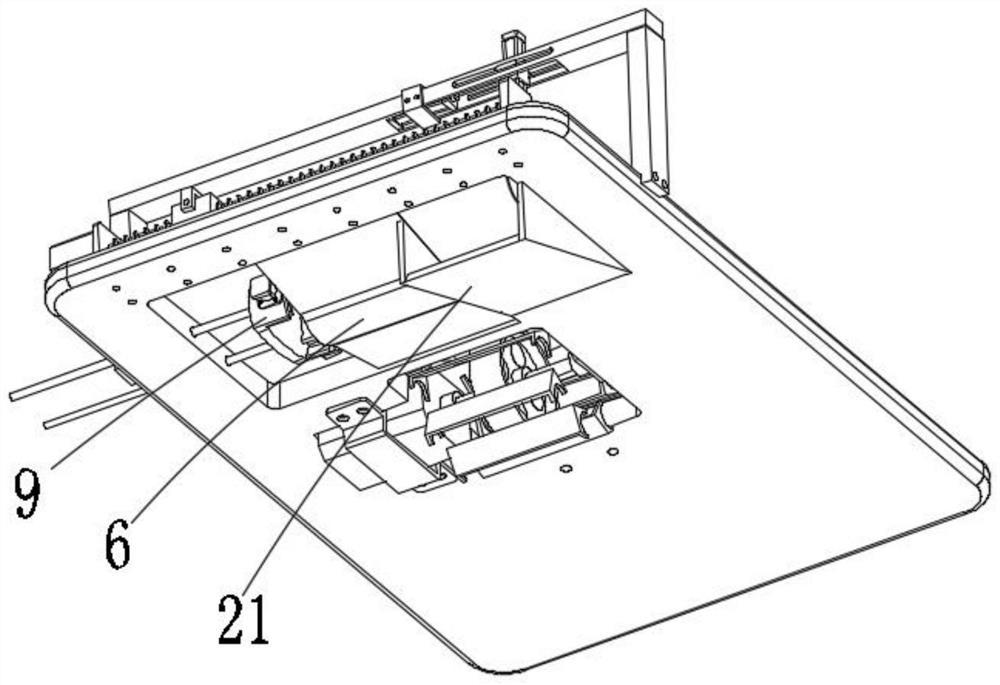

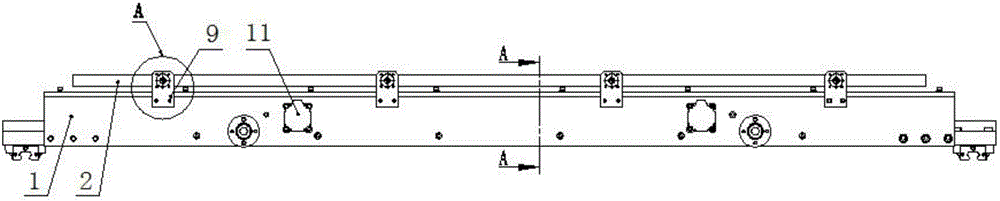

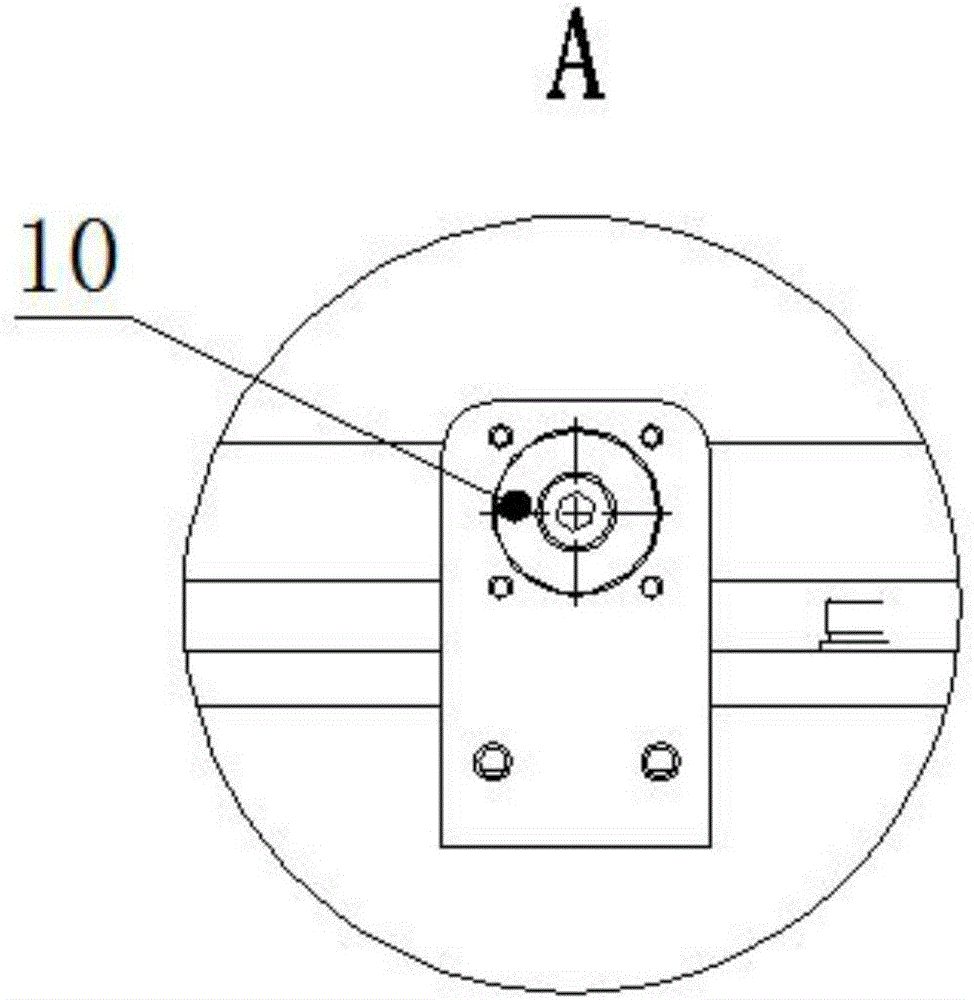

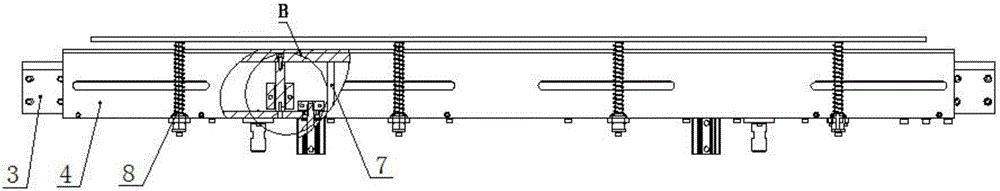

Automatic measurement equipment for profile and position of logo mounting hole

InactiveCN104482883AReduce cost pressureImprove measurement efficiencyUsing optical meansEngineering

The invention relates to the field of measurement equipment, in particular to automatic measurement equipment for the profile and the position of a logo mounting hole. The automatic measurement equipment comprises a processing device as well as three precision servo motion platforms and five cameras which are controlled by the processing device, wherein a first precision servo motion platform drives a first camera and a second camera to perform shooting scanning on two long edges of a rectangular casing of a to-be-measured product, a second precision servo motion platform drives a third camera and a fourth camera to perform shooting scanning on two short edges of the rectangular casing of the to-be-measured product, a third precision servo motion platform drives a fifth camera and a second camera to perform shooting scanning on the logo mounting hole of the to-be-measured product, and the processing device can calculate the profile and the position of the logo mounting hole according to the measurement data provided by the five cameras. The automatic measurement equipment can be well applied to the application condition of batch product manufacture.

Owner:HANS LASER TECH IND GRP CO LTD

Flexible loading type carbon fiber loaded CoB catalyst and preparation method thereof

InactiveCN105107509ALarge specific surface areaSmall specific surface areaMetal/metal-oxides/metal-hydroxide catalystsFiberCarbon fibers

The invention discloses a flexible loading type carbon fiber loaded CoB catalyst and a preparation method thereof. The preparation method comprises the steps of arranging carbon fibers into a nitric acid solution being 90 DEG C, heating and activating; putting the carbon fibers which are activated through nitric acid into a silver ammonia solution, and impregnating for 4h at normal temperature for sensibilization; adding a sodium hydroxide solution into a plating solution prepared by mixing a cobalt precursor, tartaric acid, ammonium chloride and borax, adjusting the pH value of the plating solution, stirring uniformly, then adding sodium borohydride, completely soaking the carbon fiber carriers subjected to sensibilization into the solution, and reacting in an oil bath at 45 DEG C; and after no bubble is generated, filtering, washing and drying. According to the catalyst and the preparation method, the flexible carbon fiber with a macroscopic three-dimensional net structure is taken as a carrier, the flexible and bendable catalyst can be prepared, meanwhile, the catalyst can be instantly separated from the sodium borohydride solution conveniently due to the macroscopic three-dimensional structure, and the emergency stop control of hydrogen generation by hydrolysis of sodium borohydride can be realized.

Owner:徐金富

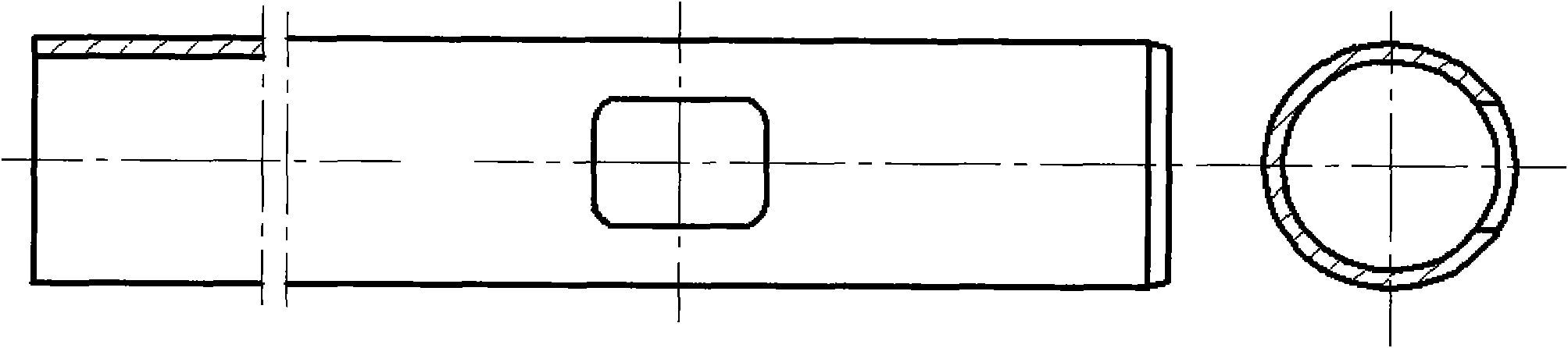

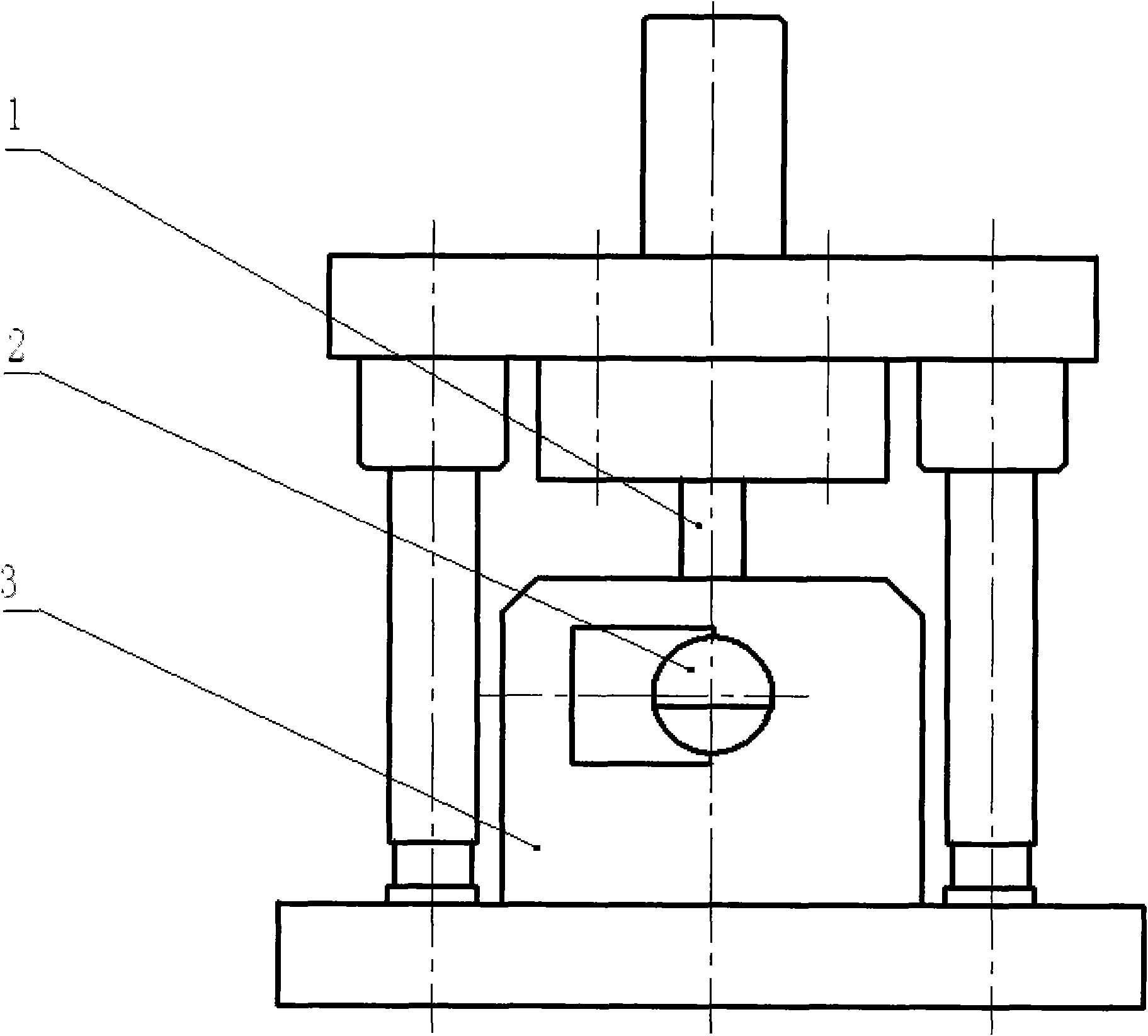

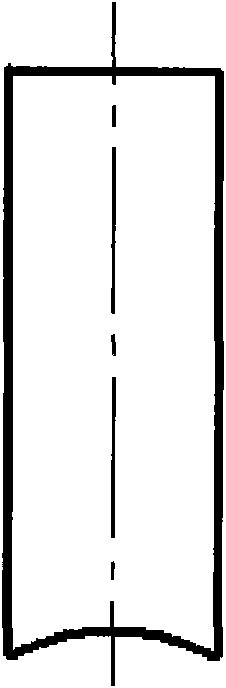

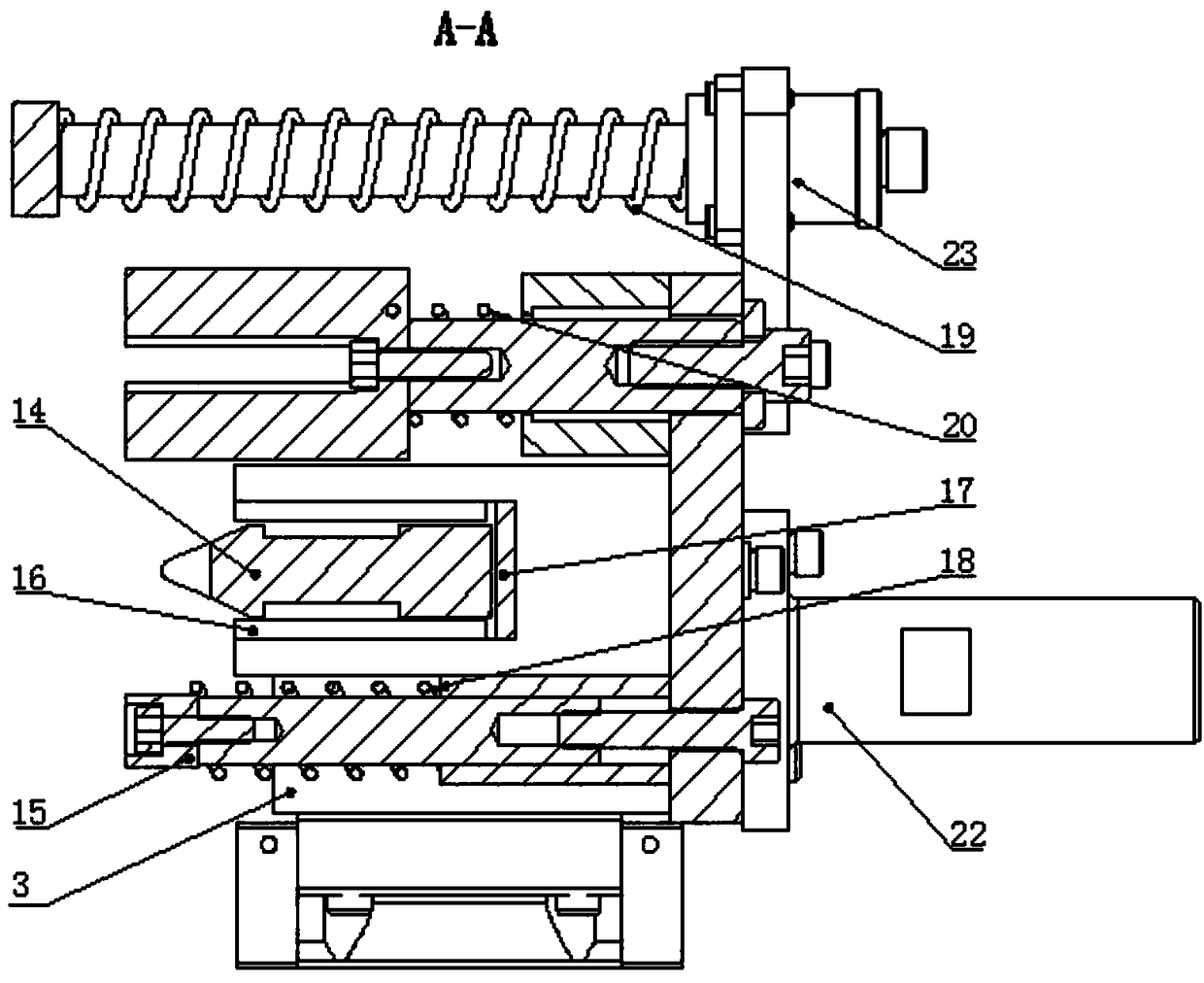

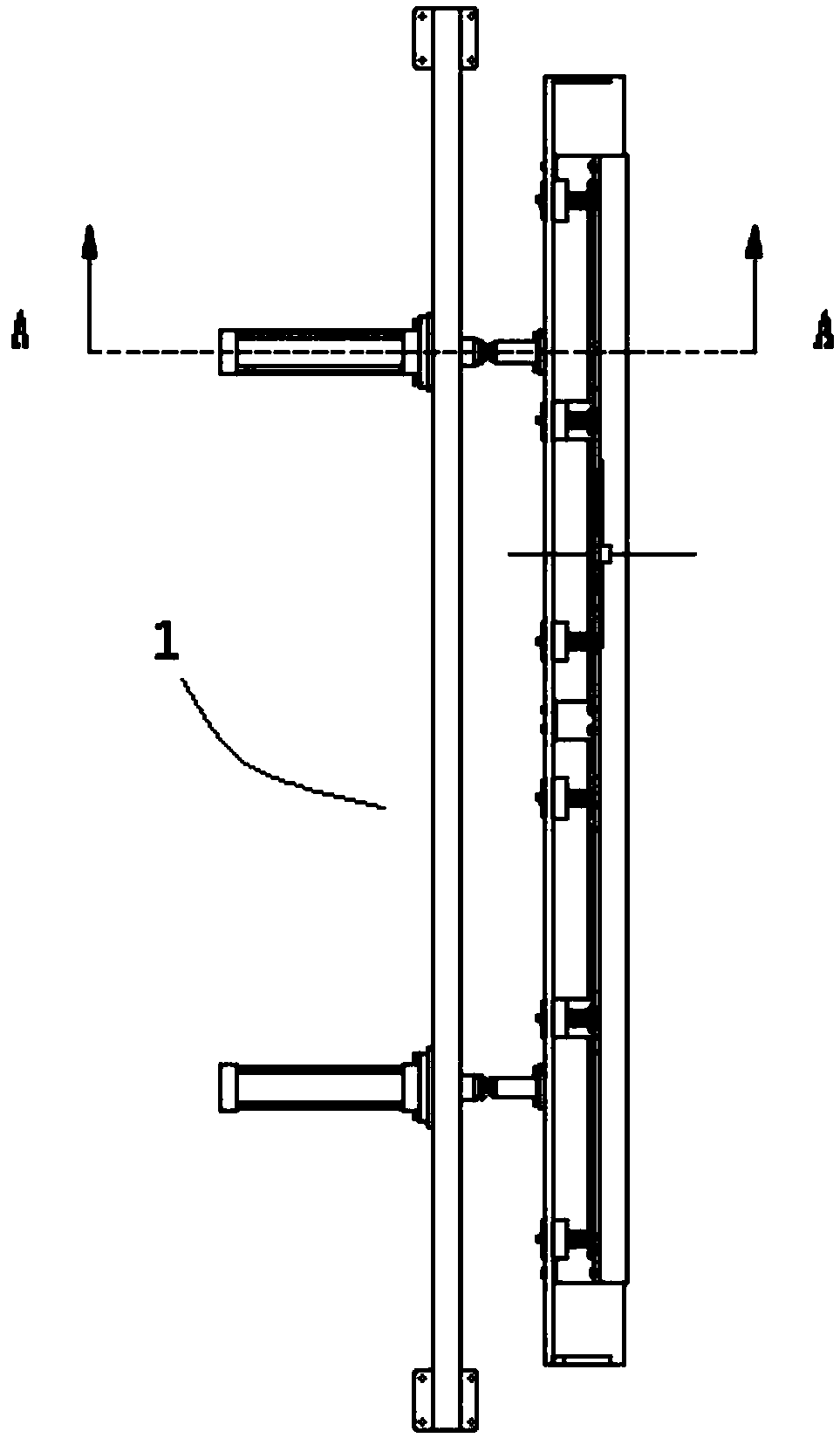

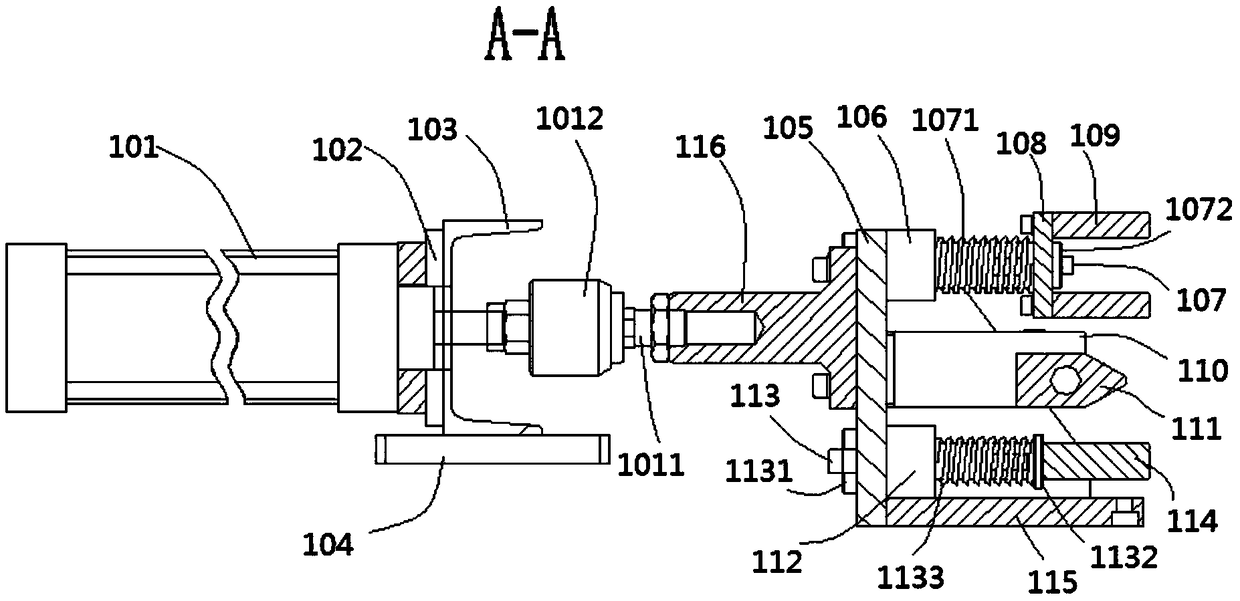

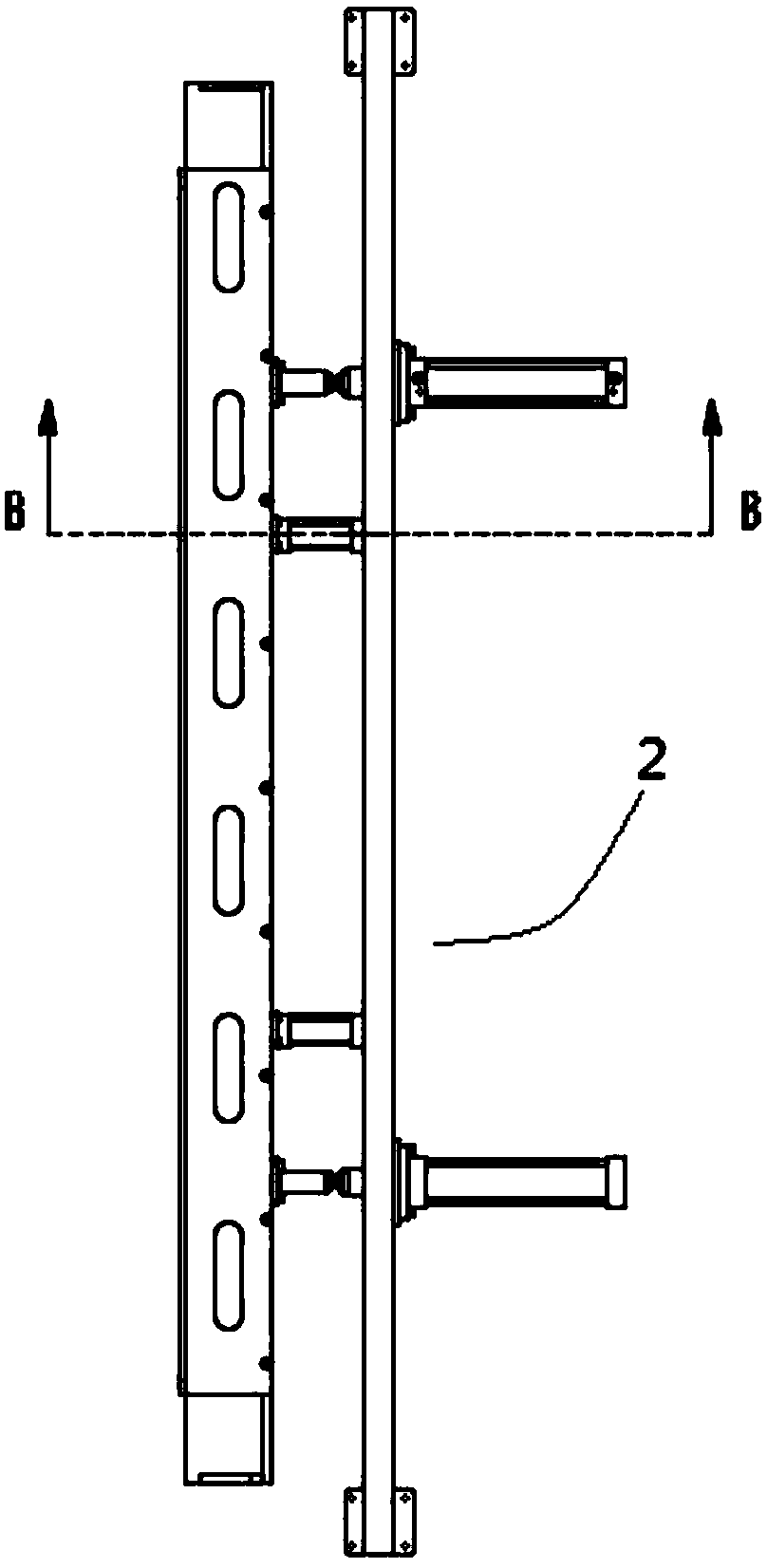

Column tube single face square opening punch forming processing method

A column tube single face square opening punch forming processing method includes that a special die is adopted to process a column tube single face square opening on a 40T common punch device, the special die is composed of special components of an inner R type cutting edge terrace die, a replaceable wedge type die, a wedge type discharging insert and the like. The processing method includes concrete steps that: (1) punch stroke is adjusted, and bottom dead center is at the position exactly cutting off the wall of the square opening; (2) the orifice blade width of the replaceable wedge type die is 3-4mm, and main body is finished into square cone with small orifice and large cavity; (3) inner R of the cutting edge terrace die is consistent with outer R of the processed column tube; (4) the oblique angles the insert of the replaceable wedge type die and the wedge type discharging insert are all 4 degrees; (5) part processing, namely inserting part into the die, wedging the die, wedgingthe discharging insert and die cutting, is carried out. The column tube single face square opening processed by the invention is uniform and consistent in hole pattern and R, prism is burr-free, roughness reaches Ra1.6, appearance is beautiful, processing efficiency is high, processing precision meets the requirement that tolerance is less than 0.1mm, and the service life of easily damaged die can reach 20000-30000 pieces. Pipe stress is uniform in terrace die cutting, and orifice deformation is small; and the die not only can strengthen tube pillar inner hole but also can be fast dismounted,and need of rapid production is satisfied.

Owner:重庆长风机器有限责任公司

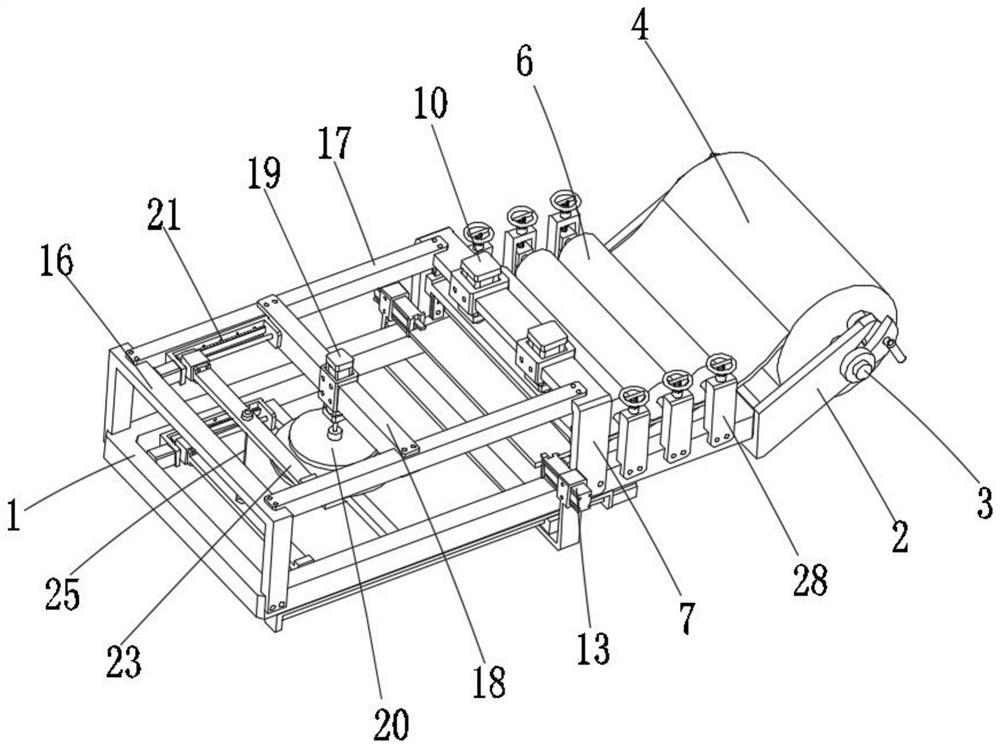

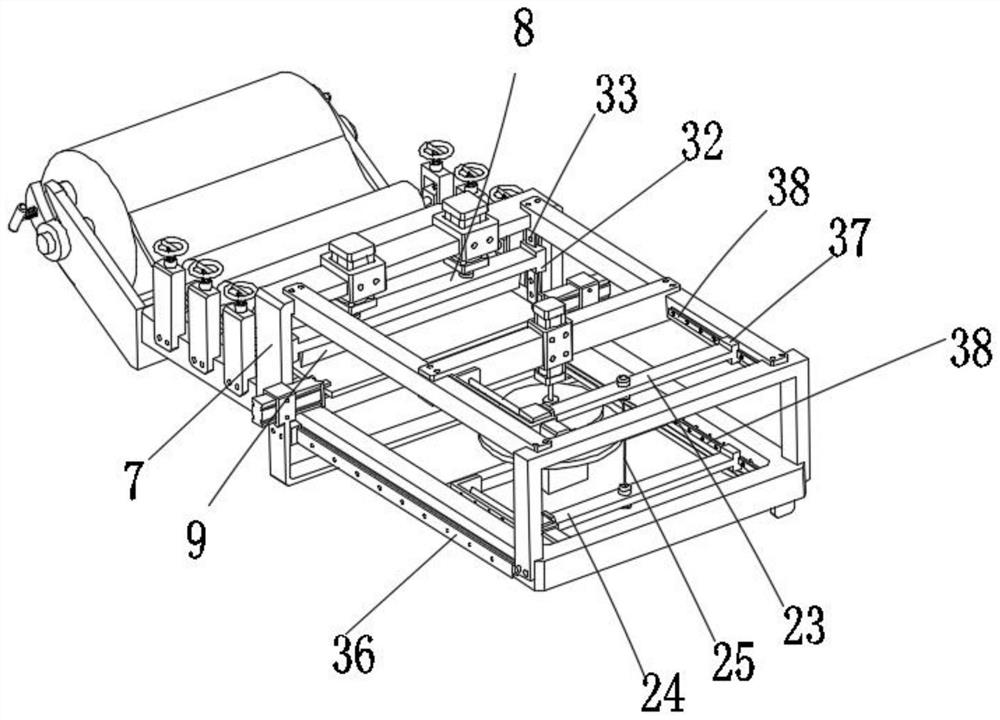

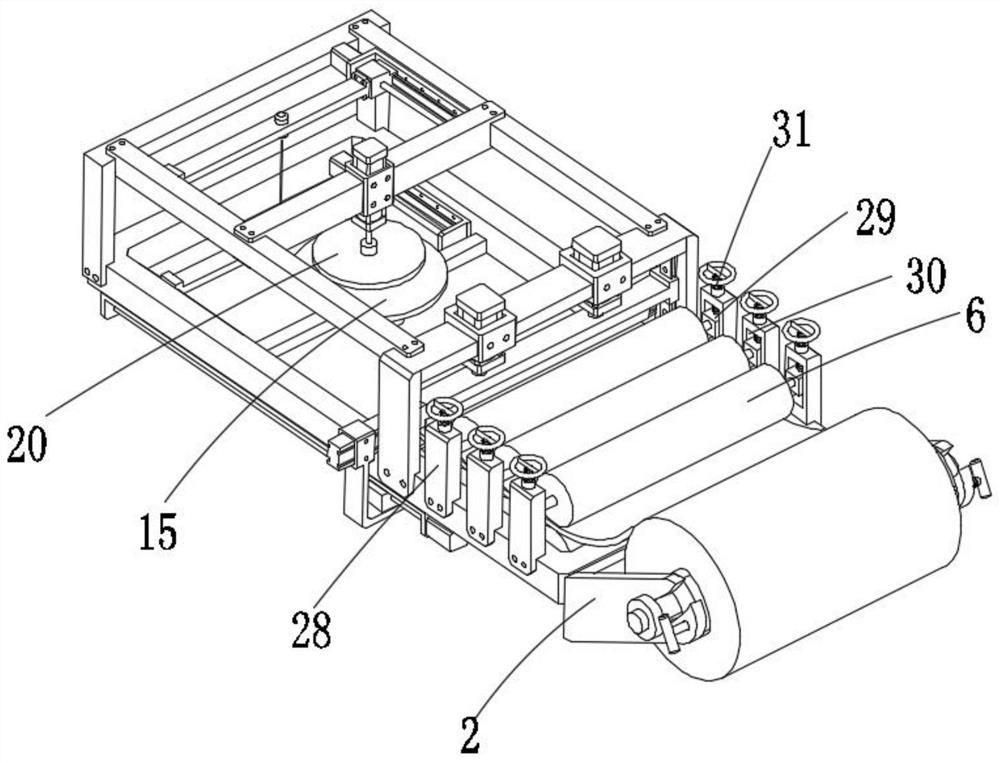

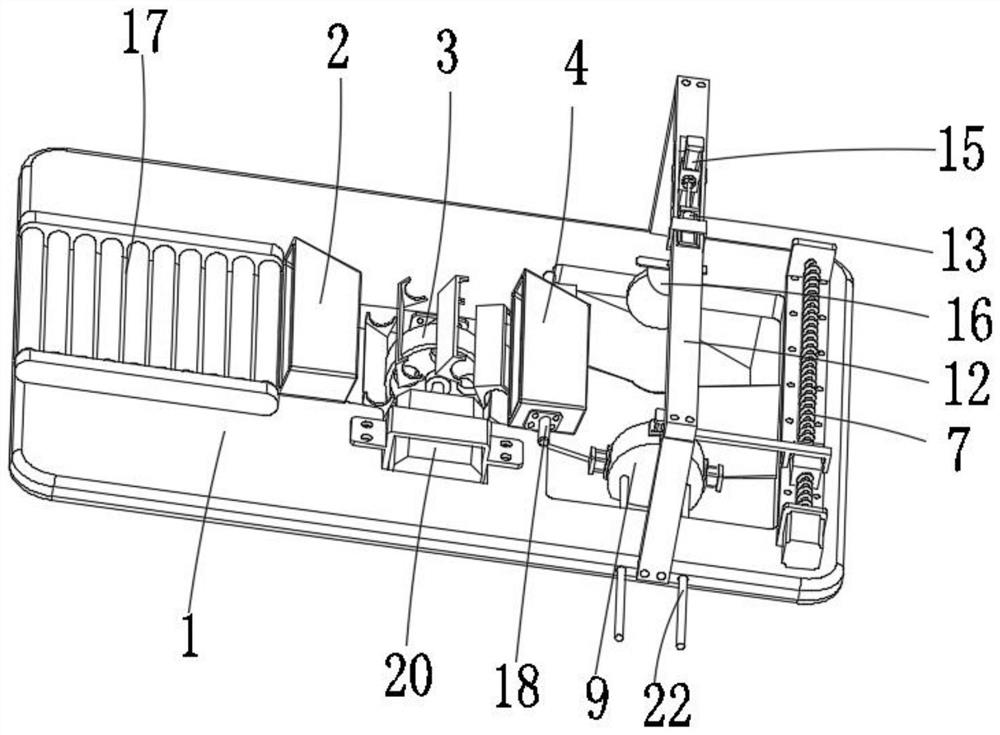

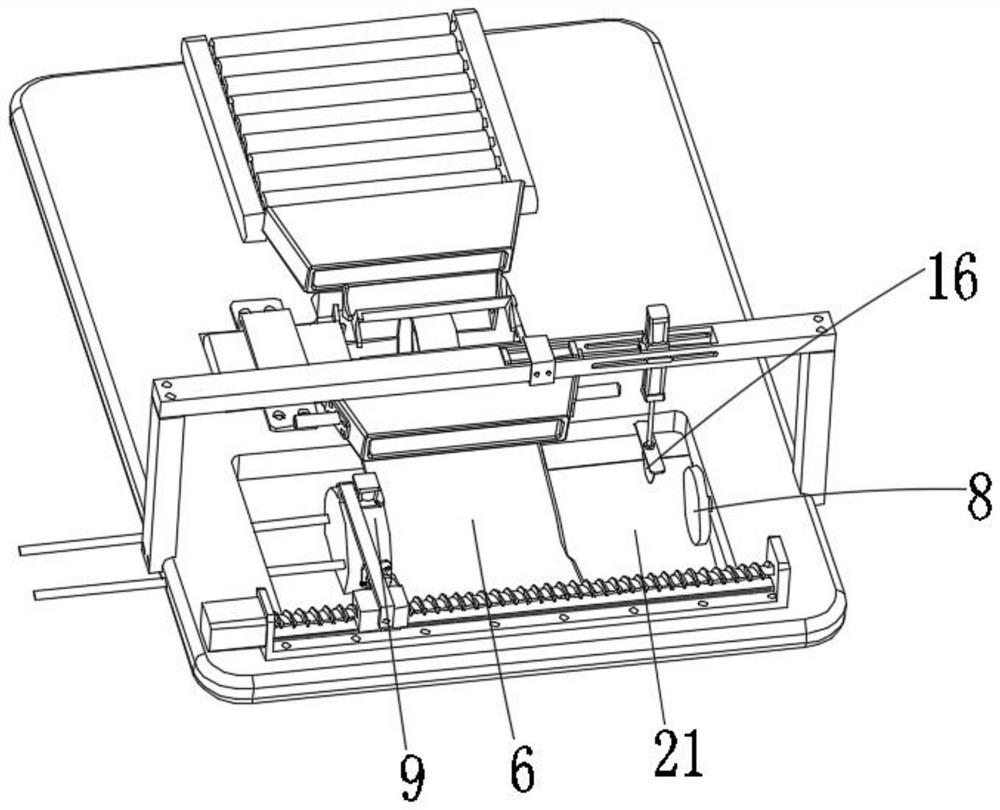

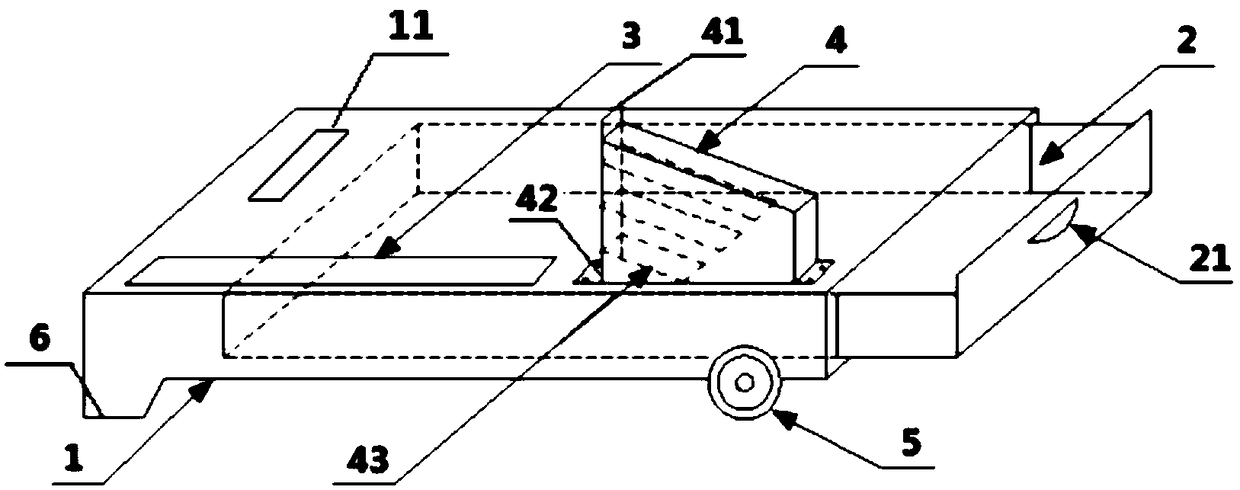

Sponge cutting device for massage chair production

InactiveCN111941520AImprove cutting efficiencyReduce labor intensityMetal working apparatusPhysical medicine and rehabilitationMassage

The invention relates to the field of massage chairs, in particular to a sponge cutting device for massage chair production. The device comprises a rectangular working frame, the right side of the rectangular working frame is fixedly connected with an unwinding frame, a sponge roll wound by a reel is erected in the unwinding frame, and a plurality of groups of lower pressing wheels rotationally connected through a lower wheel shaft are arranged in the right part of the rectangular working frame. A plurality of sets of upper pressing wheels rotationally connected through adjusting components are arranged at the upper side of the right portion of the rectangular working frame. A cutter component is arranged in the middle of the rectangular working frame. According to the sponge cutting device, a sponge belt is automatically pulled out of the sponge roll, the required sponge size is cut off, meanwhile, the cut sponge belt is conveyed between a rotary disc and a fixed disc, the labor intensity of staff is reduced, the cutting efficiency is improved, and then the subsequent sponge belt cutting efficiency is improved; and meanwhile, continuous sponge belt cutting is achieved, the spongebelt cutting efficiency is further improved, and the requirement for rapid production of enterprises is met.

Owner:JIAXING WEITELA ELECTRICAL SCI & TECH CO LTD

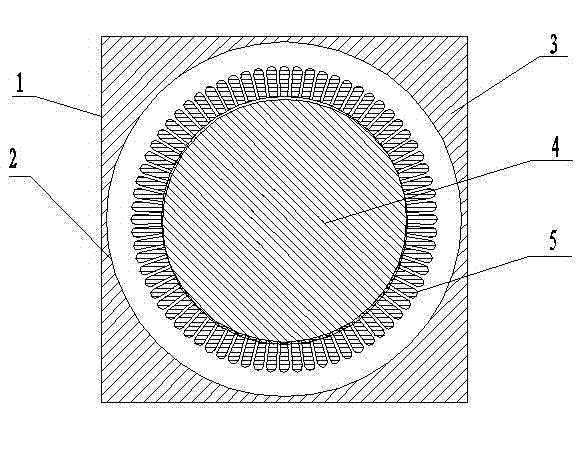

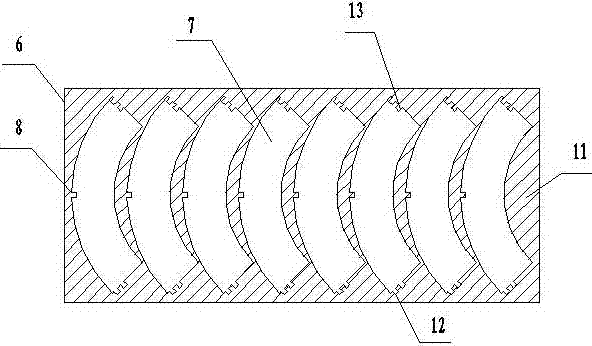

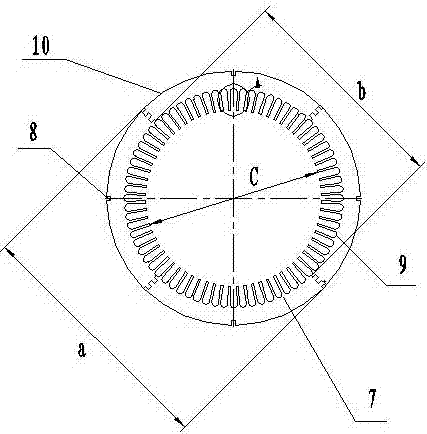

Processing method of motor stator end plate

The invention discloses a processing method of a motor stator end plate. The processing method of the motor stator end plate comprises the steps of (1) cutting a bar stock; (2) using a dedicated die to carry out blanking on arc-shaped blocks with locating grooves; (3) carrying out circle splicing, carrying out two-sided burn-in on splicing connectors through welding rods, and carrying out polishing to achieve smoothness; (4) using an outer circle and the locating grooves to carry out locating, and punching groove profiles. When the processing method of the motor stator end plate is adopted, due to the facts that an original complete circle structure is replaced by an arc-shaped splicing structure, cutting of a square stock is changed into cutting of the bar stock, and an inner circle does not need to be cut, and waste of the area of an inner disk is avoided; due to the fact that the amount of waste produced through blanking of the arc-shaped blocks is much smaller than that of waste produced through cutting of the outer circle, waste of steel plate materials is reduced by about 70%, the use ratio of the materials is greatly improved, and the profit and the competition level of enterprises are greatly improved; in addition, due to the facts that the outer circle and the locating grooves are simultaneously used for locating and punching of the groove profiles, and the groove profiles can be directly punched through a high-speed notching press, the notching speed is high, operation can be carried out through only one person, the punching speed is increased to 300-400 times per minute from 70-80 times per minute of the traditional technology, production efficiency is high, and the requirement for mass rapid production can be met.

Owner:JIANGSU TONGDA POWER TECH

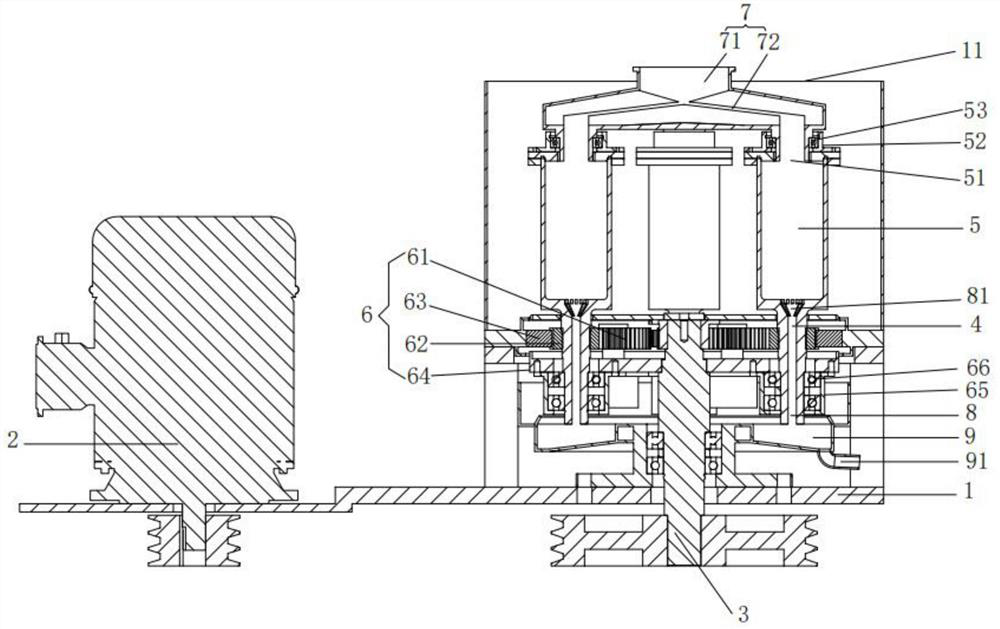

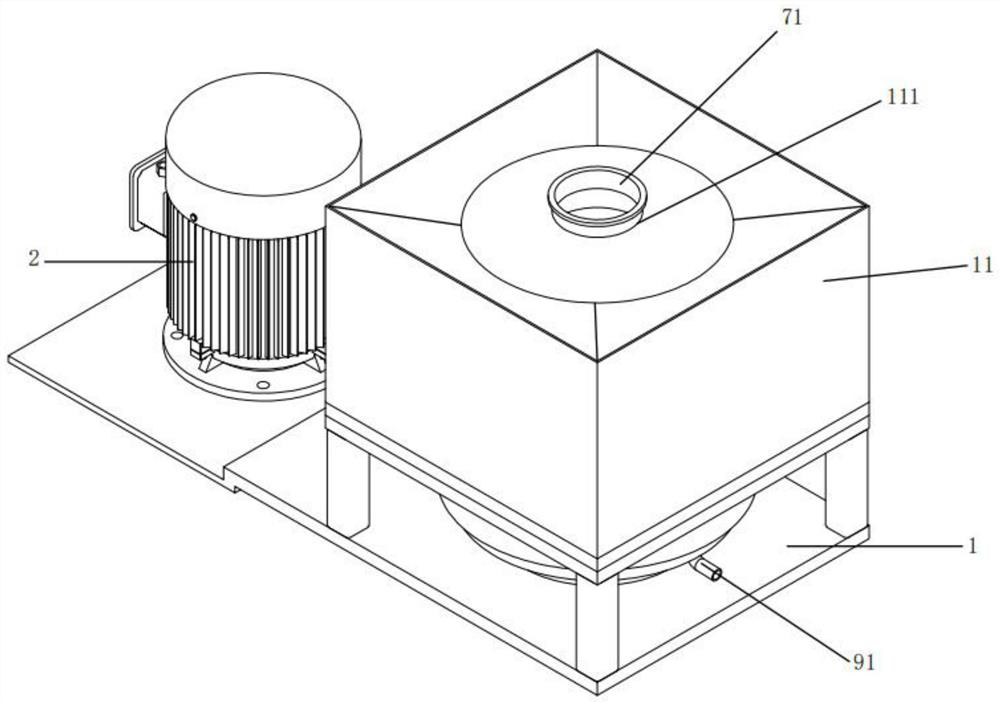

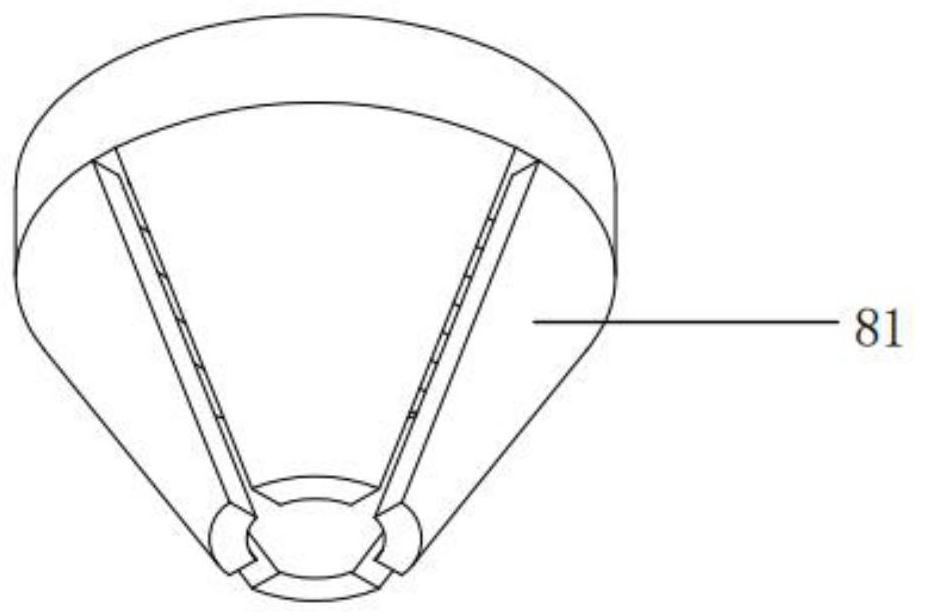

Continuous vertical planetary ball grinder

The invention discloses a continuous vertical planetary ball grinder which comprises a rack. A motor, a transmission spindle, a planetary gear mechanism, a ball grinding tank, a grinding tank shaft, acontinuous feeding hopper and a discharging opening arranged at the lower end of the ball grinding tank are arranged on the rack. The planetary gear mechanism comprises a gear ring, a sun gear, a planetary gear and a planetary carrier. The gear ring is fixed to the rack. The sun gear and the gear ring are engaged with the planetary gear. The planetary gear and the grinding tank shaft are fixedlyconnected and are coaxially and rotationally arranged on the planetary carrier. The sun gear and the planetary carrier are in transmission connection with the motor through the transmission spindle. The ball grinding tank is fixedly arranged at the upper end of the grinding tank shaft. A feed opening is arranged at the upper end of the ball grinding tank. The continuous feeding hopper comprises afeed opening and a feeding pipe, and the feeding pipe rotationally communicates with the feed opening. The grinding tanks shaft is provided with a discharging channel along the axis in a penetrating manner, wherein the discharging channel communicates with the discharging opening, and a discharging sieve is arranged in the discharging channel. The continuous feeding hopper can be combined with anautomatic assembly line to be used, the material feeding efficiency can be improved, and the rapid production requirement can be met.

Owner:长沙天创粉末技术有限公司

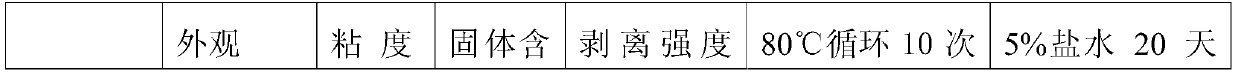

Carton composite adhesive and preparation method thereof

InactiveCN103360995AMeet the needs of rapid productionModerate viscosityNatural rubber adhesivesNon-macromolecular adhesive additivesPotassium persulfateAdhesive cement

The invention relates to a carton composite adhesive. The invention is characterized in that the carton composite adhesive is prepared from the following raw materials in parts by weight: 4-5 parts of urea, 12-15 parts of polyvinyl alcohol, 4-5 parts of melamine, 1-2 parts of tea polyphenol, 4-5 parts of guar gum, 1-2 parts of sodium hexametaphosphate, 6-8 parts of pure acrylic emulsion, 2-3 parts of itaconic acid, 2-3 parts of potassium persulfate, 4-5 parts of natural emulsion, 10-12 parts of styrene-acrylic emulsion, 3-4 parts of crosslinking agent TAIC (triallyl isocyanurate), 1-2 parts of morpholine and 100-120 parts of water. The invention provides a composite simple-component adhesive which can be directly used. The viscosity of the carton composite adhesive is moderate, and thus, the carton composite adhesive can be brushed or sprayed; and the curing speed and initial viscosity are high, and thus, the carton composite adhesive can well satisfy the quick production demands for the carton production line.

Owner:滁州市鑫彩印务有限公司

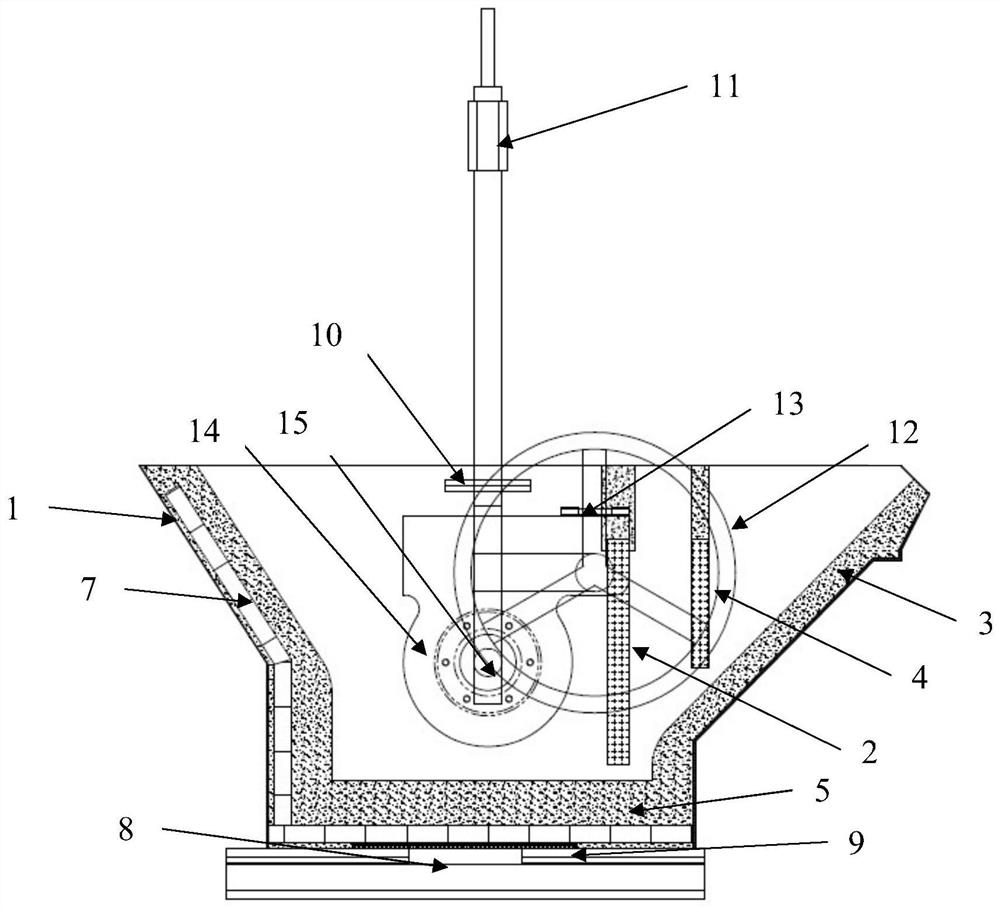

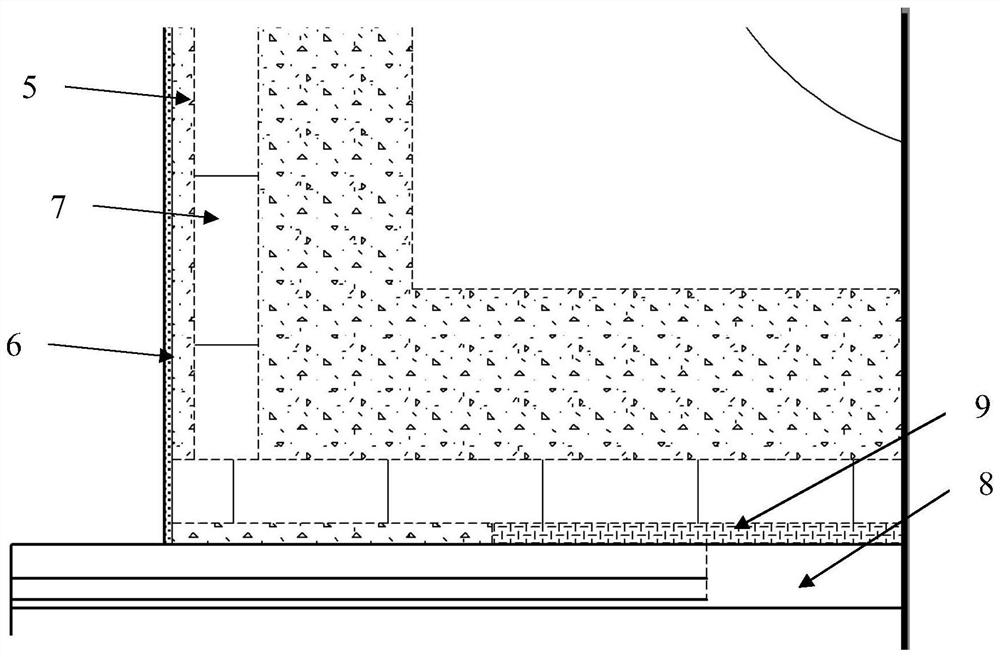

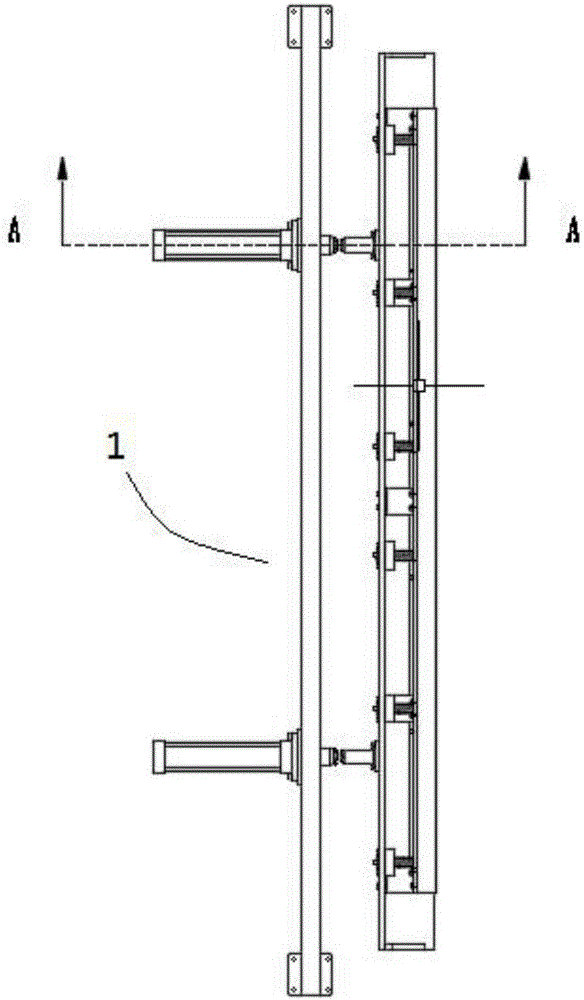

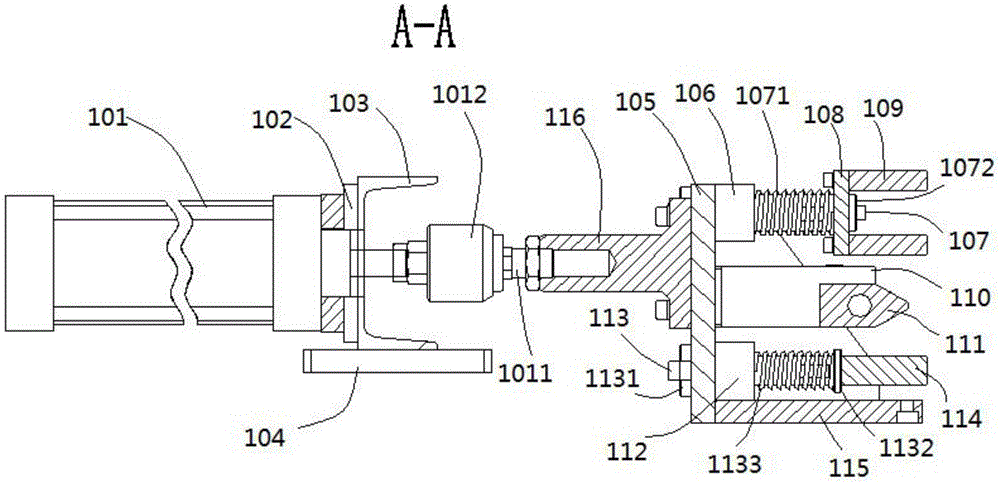

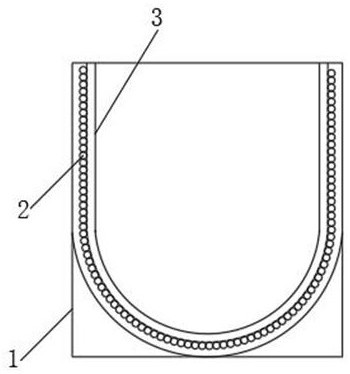

Heat insulation pouring ladle with ladle lining push-out device

InactiveCN111957940AImprove insulation effectMeet the process requirementsMelt-holding vesselsInsulation layerBrick

The invention discloses a heat insulation pouring ladle with a ladle lining push-out device. The heat insulation pouring ladle comprises a ladle shell and a ladle beam arranged on the ladle shell. Thetwo sides of the ladle shell are each provided with a ladle shell shaft, vertical rods are mounted on the ladle shell shafts, and the ladle beam is mounted on the vertical rods. The ladle shell shafts are connected with a speed reducer, and a ladle wheel is mounted on the speed reducer. A ladle nozzle is arranged on the upper edge and the edge of the ladle shell, and a primary slag blocking brickis arranged between the interior of a cavity of the ladle shell and the ladle nozzle. A communicating ladle nozzle runner is arranged along the edge of the inner side of the ladle shell, and a secondary slag blocking brick is arranged on the upper portion of the ladle nozzle runner. A heat insulation layer is further arranged between the side wall of the ladle shell and the ladle nozzle and refractory matter, and heat insulation brick layers are arranged in the position, on the ladle shell, of the refractory matter and in the position, at the bottom of the ladle shell, of the refractory matter to achieve heat insulation. The ladle wheel is rotated, so that molten steel flows out from the bottom of the ladle shell along the ladle nozzle runner. By means of the heat insulation pouring ladle, the heat insulation performance of the pouring ladle is improved; and after the pouring ladle which is just offline is cooled, a ladle lining can be dismounted, and the speed of dismounting the ladle lining is increased.

Owner:TIANJIN NEW WEISAN INDS

Working method of automatic cutting and sealing device

ActiveCN106240941AImprove automation production efficiencyShorten the timeWrapper twisting/gatheringEngineeringMechanical engineering

The invention discloses a working method of an automatic cutting and sealing device. The working method comprises the steps that a first feeding cylinder and a second feeding cylinder are started; the first feeding cylinder and the second feeding cylinder simultaneously push a bag sealing mechanism and a bag cutting mechanism to draw close to a film bag, and the film bag is compressed by a compression plate and a cushion plate; when the distance between a hot-sealing cutter and the cushion plate is shortened to a certain degree, the film bag is heated and sealed through the hot-sealing cutter; a third feeding cylinder is started; the third feeding cylinder controls the cutter to move towards the film bag and finally cut off the film bag, and the film bag automatically falls off and covers household equipment. The automatic production efficiency of the automatic cutting and sealing device is improved through the application of the working method; and the time is saved and the requirement for quick production can be better met through the application of the method.

Owner:合肥锡玉包装材料有限公司

Heat-resistant saline-water-erosion-resistant chloroprene spray adhesive and preparation method and application thereof

ActiveCN111100583AHigh solid contentLow viscosityNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesSaline waterAdhesive

The invention discloses a heat-resistant saline-water-erosion-resistant chloroprene spray adhesive and a preparation method and application thereof. The heat-resistant saline-water-erosion-resistant chloroprene spray adhesive is prepared from the following raw materials in parts by weight: 120-140 parts of chloroprene rubber, 10-25 parts of chlorinated rubber, 90-120 parts of phenolic resin and the like. The chloroprene spray adhesive resistant to heat and saline water erosion can meet the requirements of spray adhesives for ocean containers for temperature and saline water resistance, the high temperature resistance can reach 70-100 DEG C, and the requirement for continuous high-temperature sailing of the ocean containers in a high-temperature sea area is met; and a uniform film can be formed on the metal plate through glue spraying, salt in seawater is prevented from making contact with the metal plate, the metal plate is prevented from being corroded and rusted, the obtained glue film is not degummed within 20 days after being soaked in saline water with the mass concentration being 5%, the saline water cannot permeate the glue film to corrode the alloy aluminum plate, and the salt water resistance is excellent.

Owner:SHANDONG NORTH MODERN CHEM IND

A cutter mechanism for intelligent bagging equipment

Owner:ANHUI YOURFRIEND PULP MOLDING TECH

Bag opening device for intelligent bagging equipment

Owner:安徽永锋智能包装科技有限公司

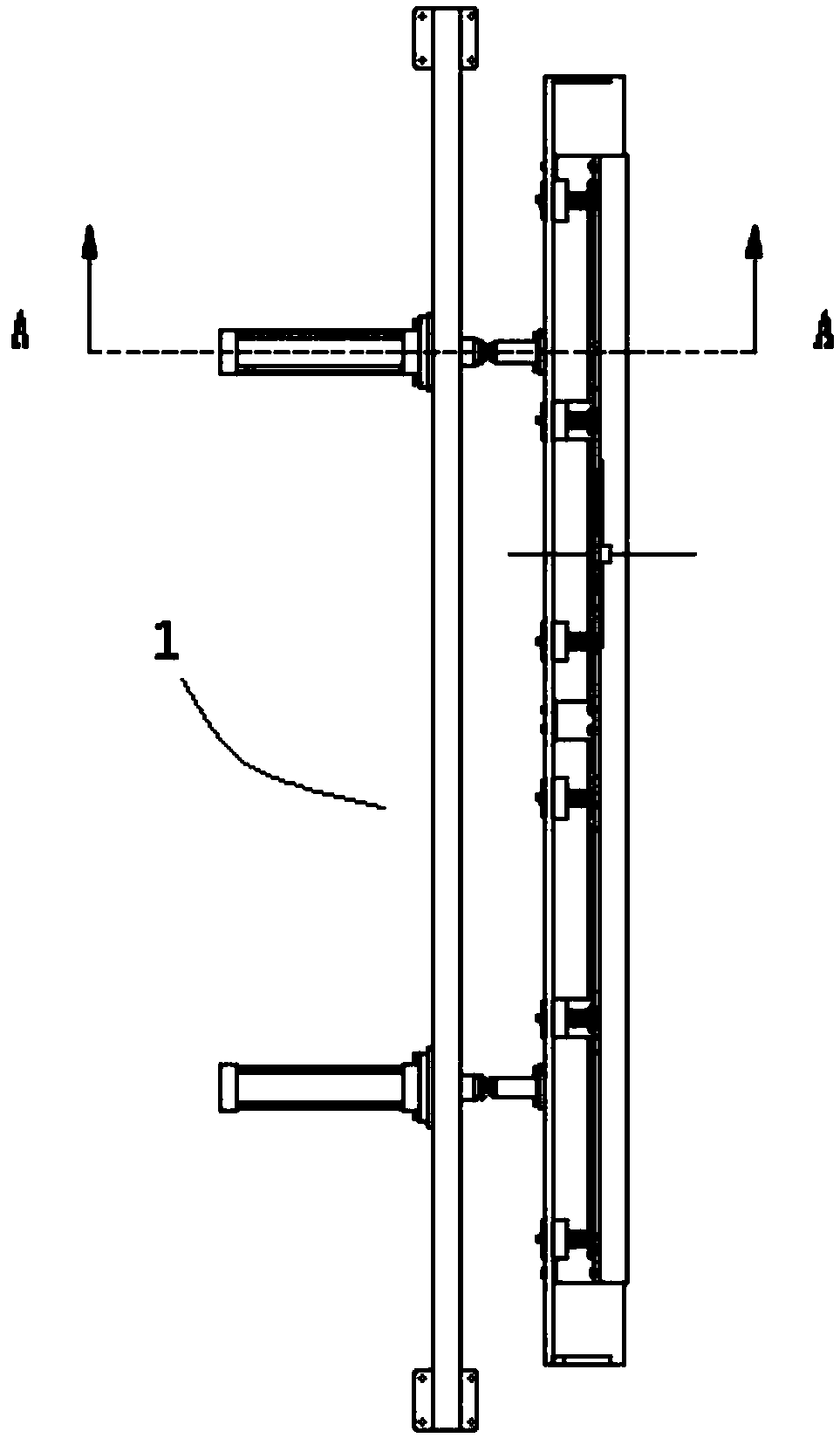

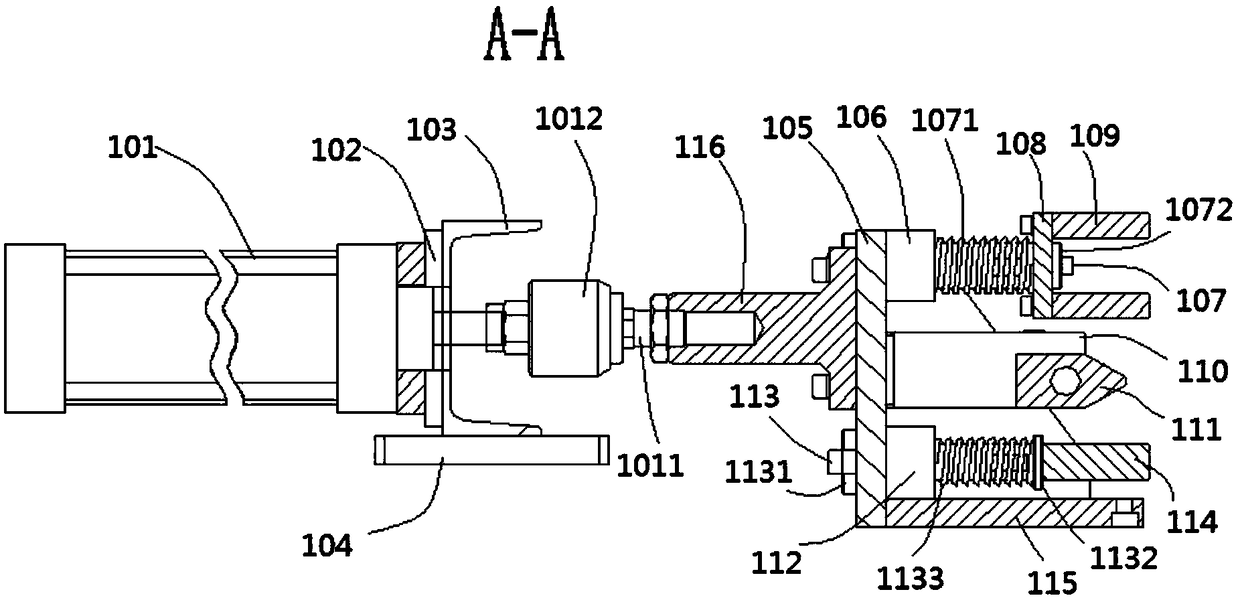

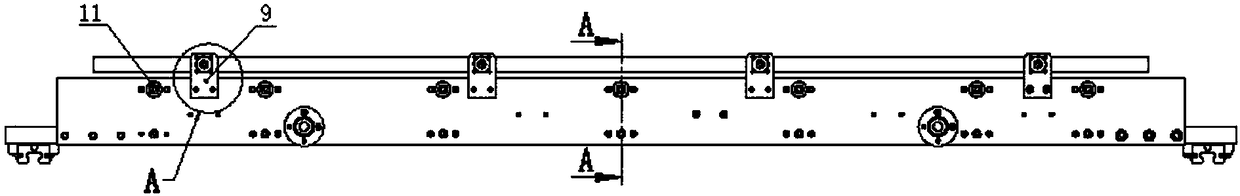

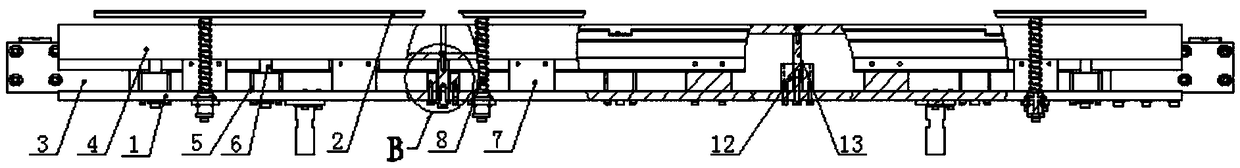

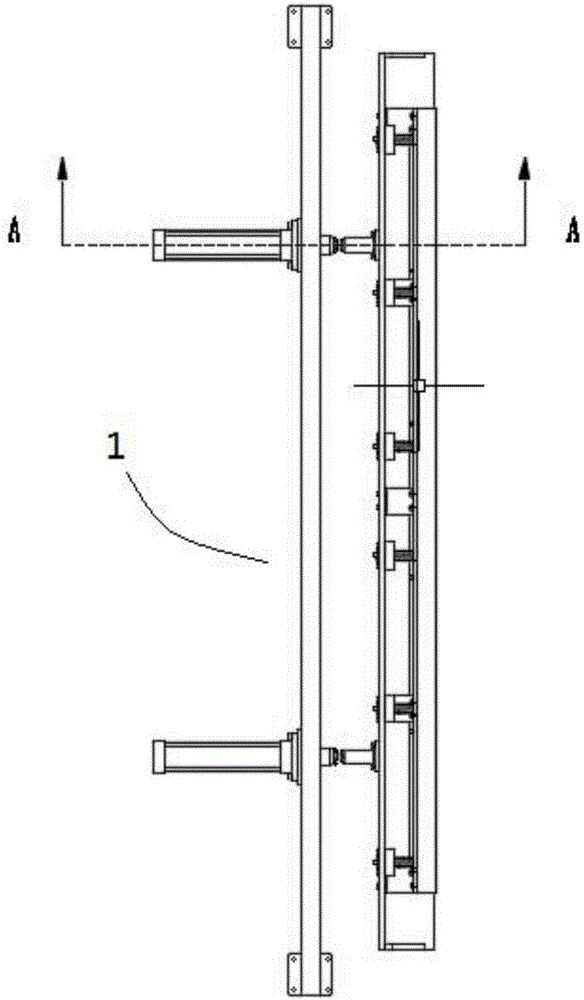

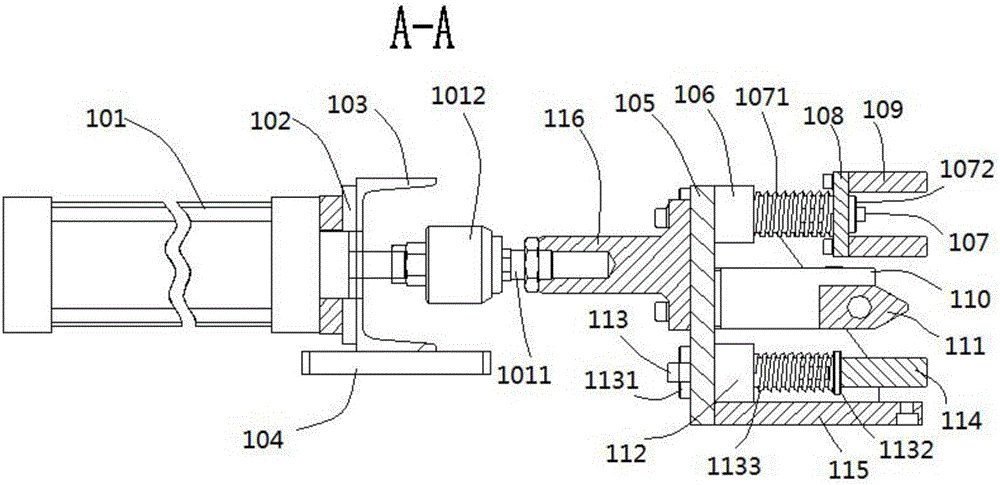

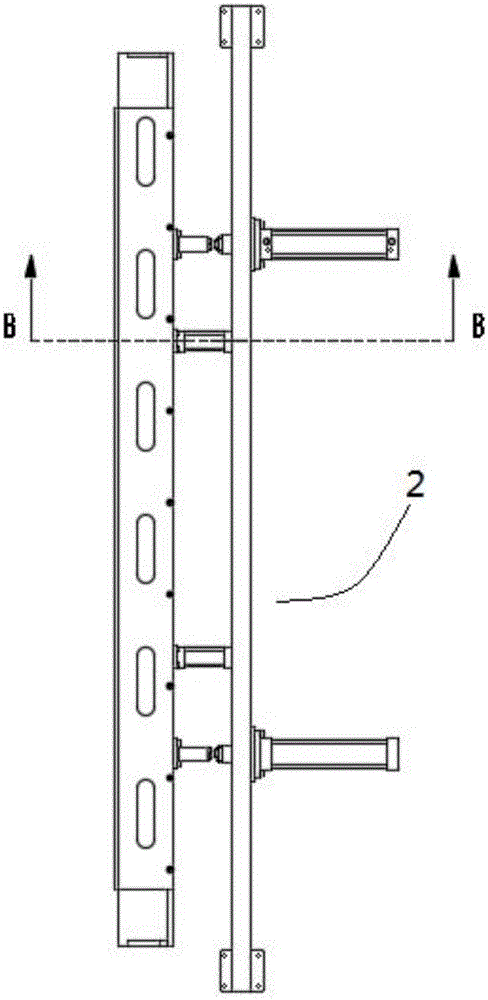

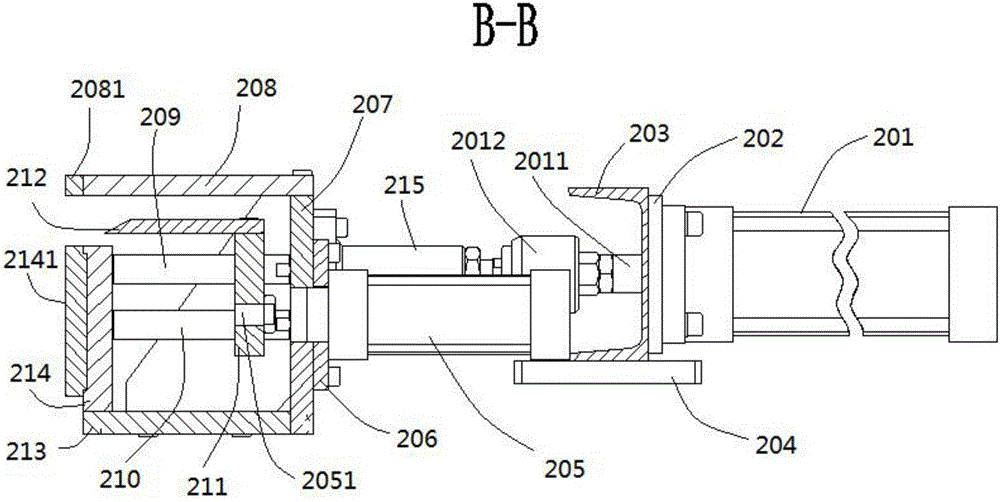

Connecting fixed structures and transport devices

ActiveCN104832505BEasy to separateAchieve separationSecuring devicesEngineeringMechanical engineering

Owner:GREE ELECTRIC APPLIANCES INC

A working method of an intelligent bag sealing mechanism

ActiveCN106275621BImprove the level of automated productionShorten the timeWrapper twisting/gatheringMechanical engineering

Owner:ANHUI YOURFRIEND PULP MOLDING TECH

A heat-sealing mechanism for intelligent bagging equipment

ActiveCN106314897BQuality improvementImprove efficiencyWrapper twisting/gatheringEngineeringMechanical engineering

Owner:合肥锡玉包装材料有限公司

A working method of an automatic cutting and sealing device

ActiveCN106240941BImprove automation production efficiencyShorten the timeWrapper twisting/gatheringEngineeringCushion

Owner:合肥锡玉包装材料有限公司

Working method for intelligent bag sealing mechanism

ActiveCN106275621AImprove the level of automated productionShorten the timeWrapper twisting/gatheringEngineeringMechanical engineering

Owner:ANHUI YOURFRIEND PULP MOLDING TECH

A fixed-width cutting device for film packaging sticking line production

ActiveCN111923134BRealize continuous cuttingAchieve rapid continuous cuttingMetal working apparatusMechanical engineering

Owner:惠州市骅鹰电子科技有限公司

Device for preventing spark fly and dust collection for cutter

PendingCN108942387AChange flyingAvoid harmMaintainance and safety accessoriesFire - disastersEngineering

The invention discloses a device for preventing spark fly and dust collection for a cutter. The device comprises a base, wherein a cutting blade inlet and an extinguishing-protecting cover are separately arranged on the surface of the base; a drawer type dust collecting box is arranged at one side of the base; the extinguishing-protecting cover is connected with the base through a slot hole; and acooling mechanism is arranged inside the extinguishing-protecting cover. The device can effectively prevent spark, dust and fragments from flying to cause harm on construction staff, prevents occurrence of a fire disaster, and reduces safety production hidden danger.

Owner:CNOOC ENERGY TECH & SERVICES +1

Water-based adhesive for interior trim of automobile

ActiveCN102876257BEasy to use and flexibleGood value for moneyNon-macromolecular adhesive additivesMacromolecular adhesive additivesWater basedPolymer science

The invention belongs to the technical field of synthetic rubber adhesive and discloses a water-based adhesive for the interior trim of an automobile and a method for preparing the water-based adhesive. The water-based adhesive is prepared from the following raw materials by weight: 65-90 parts of neoprene latex, 5-25 parts of polymer emulsion, 0.2-0.8 part of aqueous thickener, 0.1-0.5 part of an aqueous cross-linking agent, 0.1-0.5 part of a pH value adjusting agent, 0.05-0.2 part of a dispersing agent and 3-10 parts of deionized water. The water-based adhesive does not contain the organic solvent, the metal oxide, the antioxidant, the filler and the like, is the one-component adhesive, can be used directly, has moderate hardness, can be coated by brushing and spraying, has high curing speed and high initial adhesion and can well meet the quick production needs of the automobile assembly line.

Owner:河南瑞朗达新材料有限公司

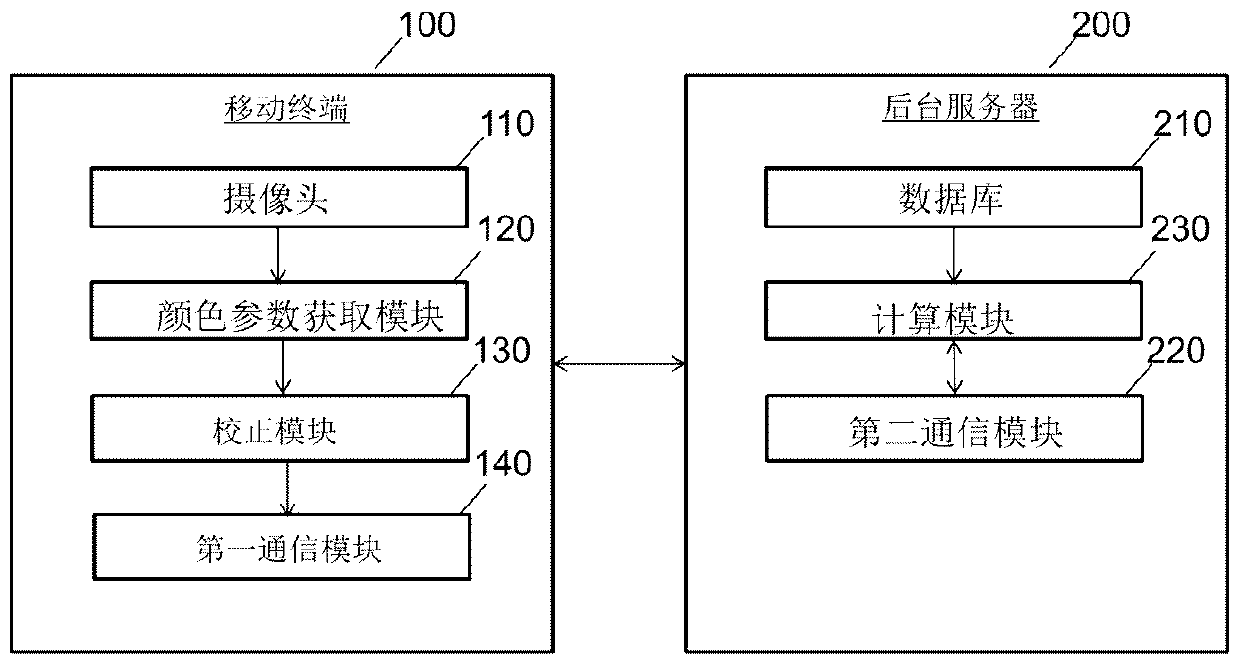

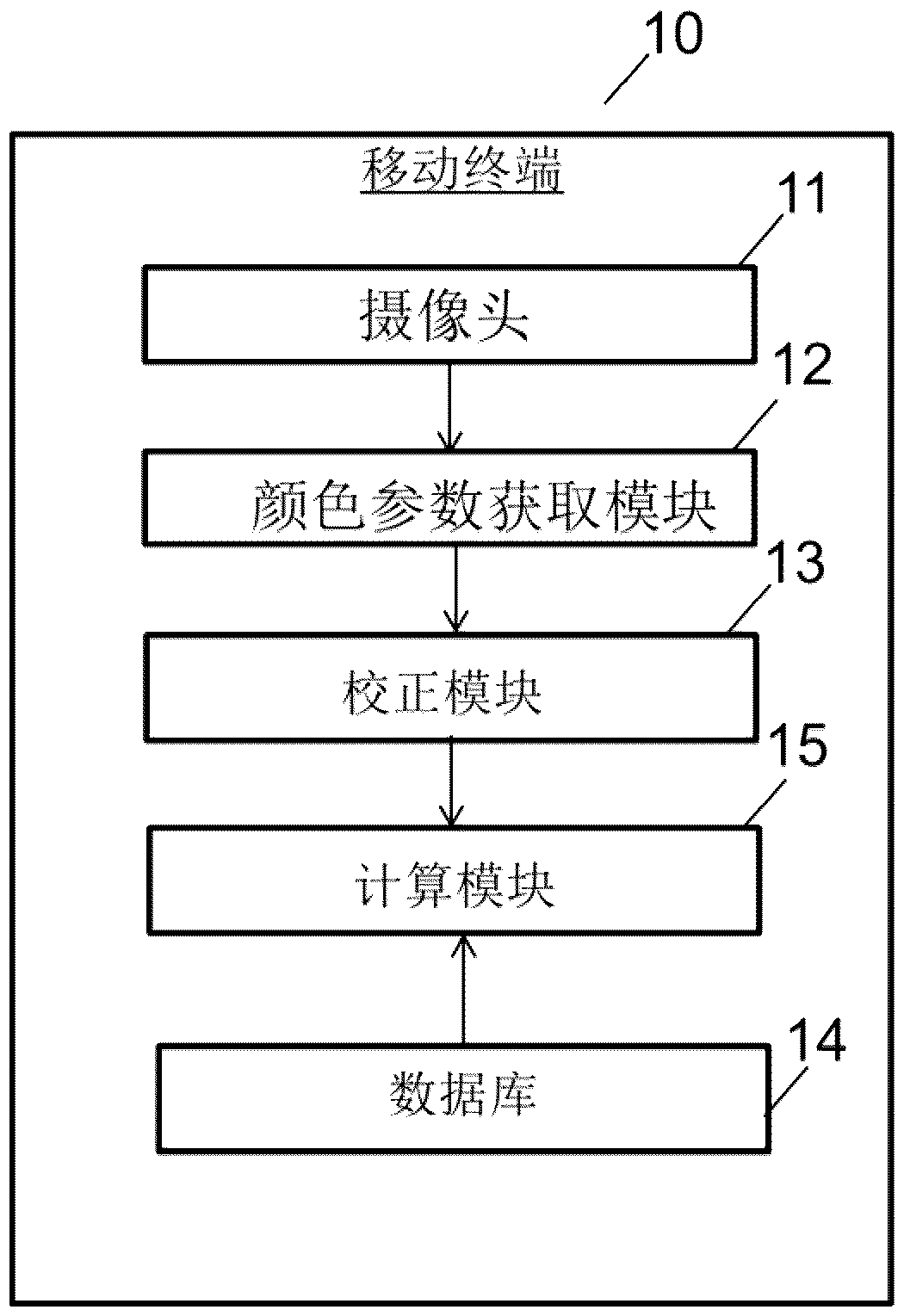

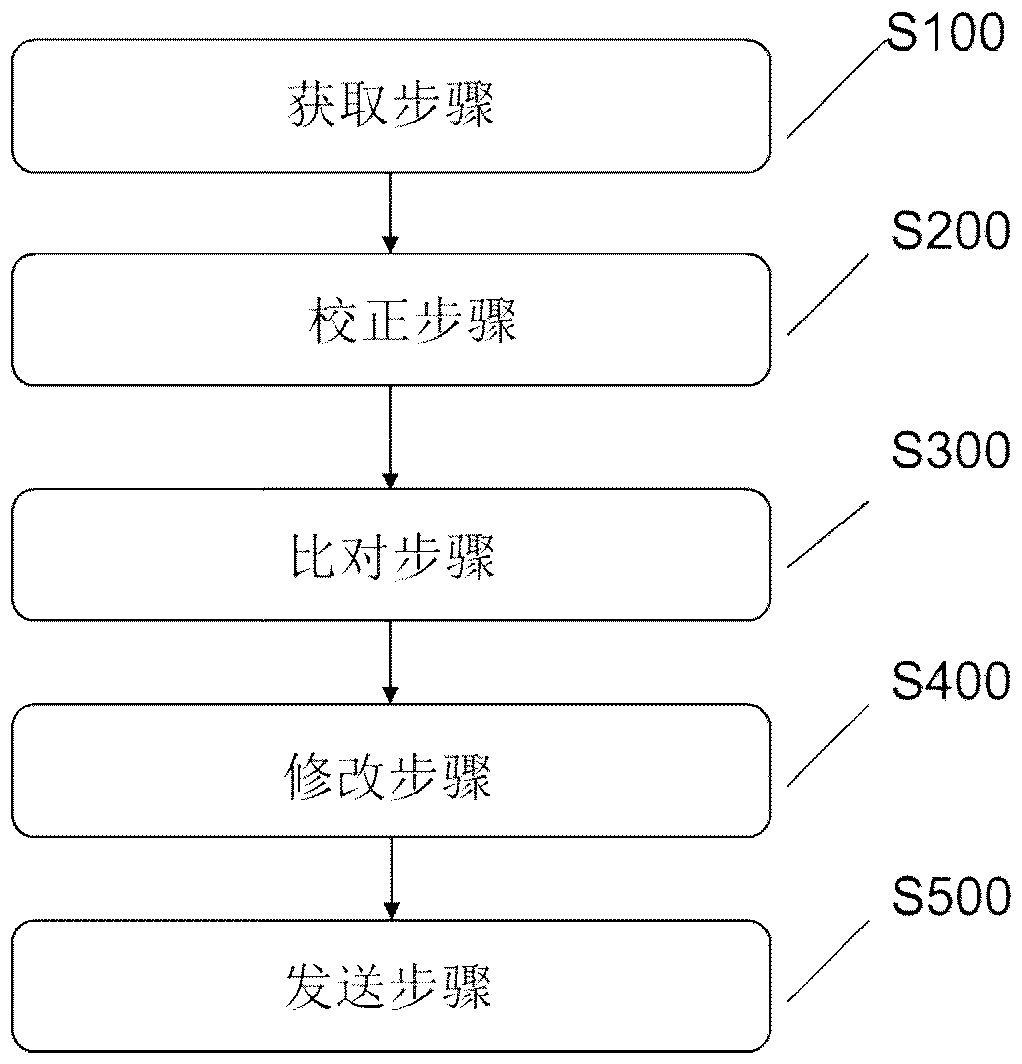

Product color correction method and product color correction system

PendingCN110969596AMeet the needs of rapid productionImage enhancementImage analysisAlgorithmColor correction

The invention relates to a product color correction method and a product color correction system. The product color correction method comprises the following steps: an obtaining step of shooting a product by using a mobile terminal to obtain a current color parameter of the product; a comparison step of comparing the current color parameter of the product with a target color parameter of the product to obtain a comparison result, and outputting the comparison result as a color parameter deviation between the current color parameter of the product and the target color parameter of the product;and a correction step of obtaining a formula correction scheme of the product color corresponding to the color parameter deviation output in the comparison step based on a first corresponding relationship between the pre-stored color parameter deviation and the formula correction scheme of the product color. According to the invention, the period of formula upgrading or color correction can be shortened, and the requirement of quick production can be met.

Owner:COVESTRO DEUTSCHLAND AG

Cutter mechanism used for intelligent bagging equipment

Owner:安徽永锋智能包装科技有限公司

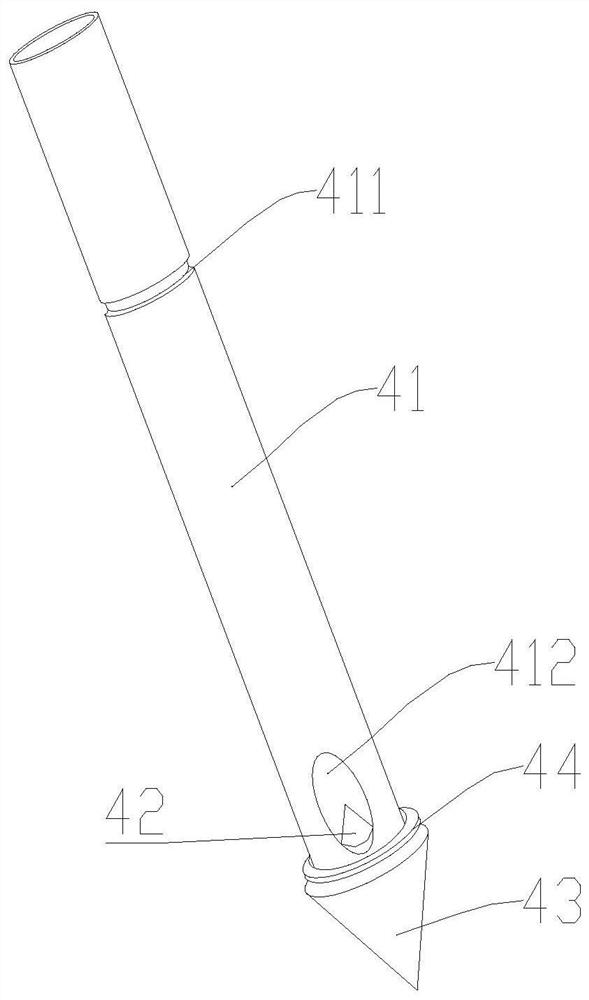

Liquid filling head

InactiveCN111892008ASimple structureEasy to disassemble and cleanLiquid bottlingPipe fittingEngineering

The invention discloses a liquid filling head. The liquid filling head comprises a first pipe fitting, a second pipe fitting, an elastic part and an infusion pipe. The lower portion of the first pipefitting sleeves the upper portion of the second pipe fitting. The elastic part is provided with a top end and a bottom end and sleeves the first pipe fitting and the second pipe fitting. The top end abuts against the outer wall of the first pipe fitting, and the bottom end abuts against the outer wall of the second pipe fitting. The infusion pipe penetrates through through cavities of the first pipe fitting and the second pipe fitting. The lower end of the infusion pipe extends out of the second pipe fitting. According to the liquid filling head, the first pipe fitting, the second pipe fittingand the elastic piece are matched, external force is acted on the first pipe fitting, the lower end of the infusion pipe is caused to stretch out and expose out of a liquid outlet, liquid is conveyedoutwards, external force is released, the infusion pipe rebounds automatically, and the liquid outlet is closed. In addition, a first fixing disc and a second fixing disc are used for fixing hangingconnection of the infusion pipe, and disassembly and cleaning are convenient. The liquid filling head is simple in overall structure, can meet requirements for quick production, and is precise in infusion amount control.

Owner:时代生物科技(深圳)有限公司

Fermentation bin for disposal of organic wastes

InactiveCN112090931AImprove heating efficiencyShorten preheating timeSolid waste disposalTransportation and packagingFiberThermodynamics

The invention relates to the technical field of disposal of organic wastes, in particular to a fermentation bin for disposal of organic wastes. The fermentation bin for disposal of the organic wastescomprises an outer frame, wherein an inner layer is welded to the inside of the outer frame; and a heating device covers the outer side of the inner layer. When the fermentation bin for disposal of the organic wastes is used, heating is carried out by using the heating device covering the outer side of the fermentation bin, and meanwhile, by using carbon fiber materials having a better heating effect, rapid improvement of the heating efficiency is achieved, the overall pre-heating time is shortened to 0.5 hour to 1 hour; and moreover, in a whole production process, energy consumption of the existing heating way is 1 / 2 to 1 / 3 of that of a conventional heating way, and thus, rapid production demands can be met, and the problems that the conventional heating way is slow in heating speed, longin time consumption and heavy in power consumption are solved.

Owner:江苏迅捷环保科技有限公司

A kind of glass UV light curing printing ink and preparation method thereof

Owner:FOSHAN CITY GREEND CHEM

An automatic bag cutting mechanism for flexible intelligent bagging equipment

The invention discloses an automatic bag cutting mechanism used for flexible intelligent bagging equipment. The automatic bag cutting mechanism comprises a first feeding cylinder, a first fixed seat, a U-shaped plate, a second fixed seat and a connector, wherein one end of the first feeding cylinder is arranged on one surface of the U-shaped plate by virtue of the first fixed seat; the output end of the first feeding cylinder is a first piston rod, and a connecting plate is arranged at one end of the first piston rod by virtue of the connector; a second feeding cylinder is arranged on the connecting plate by virtue of the second fixed seat; the output end of the second feeding cylinder is a second piston rod, and a supporting plate is arranged at one end of the second piston rod; and a cutter is arranged on the upper end of the supporting plate. According to the invention, by designing the bag cutting mechanism, space is saved, and automatic production level is improved; and by applying the mechanism, time is shortened, and quick production requirement can be beneficially met.

Owner:ANHUI YOURFRIEND PULP MOLDING TECH

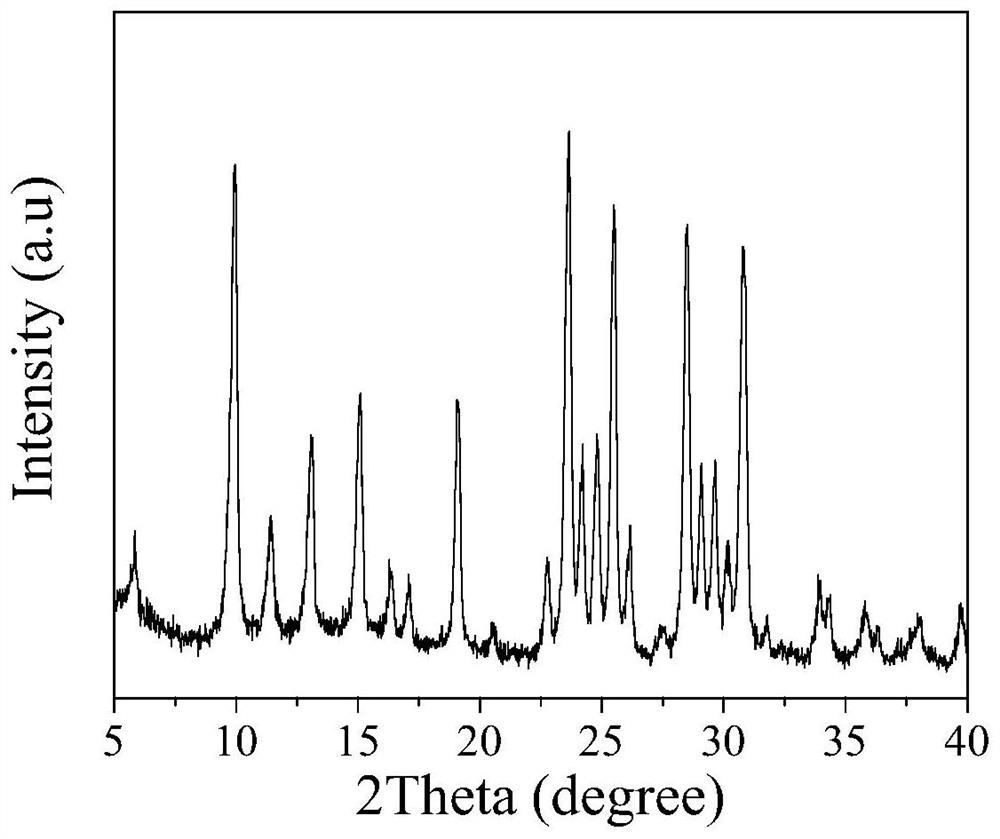

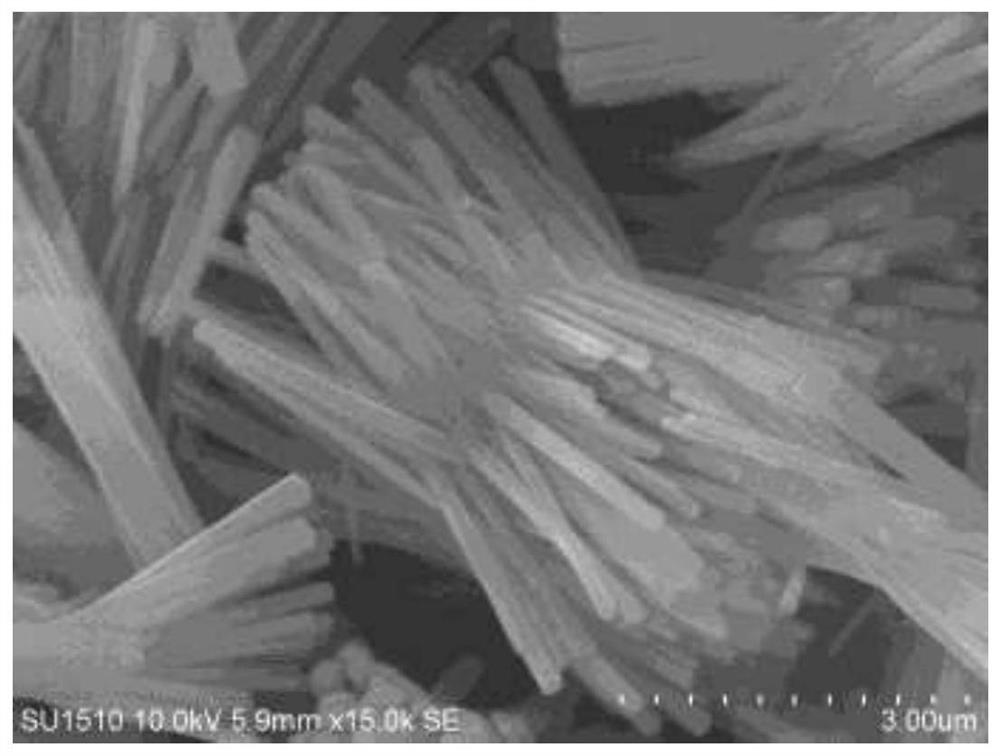

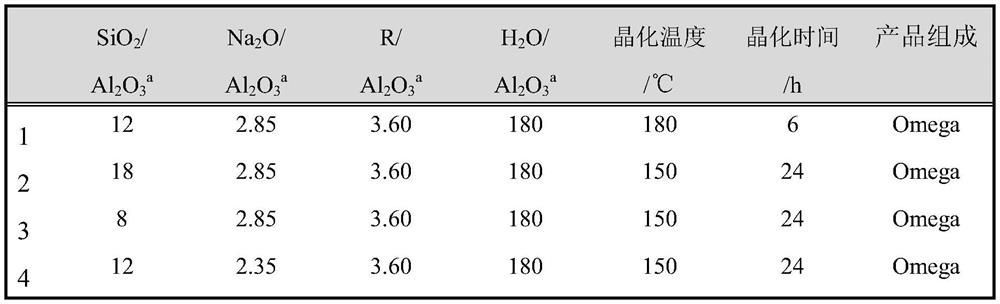

Method for synthesizing Omega zeolite molecular sieve

InactiveCN112047357AThe preparation method is simple and reliableHigh crystallinityNanotechnologyAluminosilicate zeolite type ZSM-4Molecular sievePhysical chemistry

The invention discloses a method for quickly synthesizing an Omega zeolite molecular sieve, which comprises the following steps: uniformly mixing an aluminum source, an alkali source and deionized water, and adding a silicon source with stirring; continuously stirring the solution until the solution is uniform to form silica-alumina gel, adding a certain amount of choline into the silica-alumina gel, and then stirring the gel; adding zeolite molecular sieve raw powder into a reaction kettle, then putting the gel into the reaction kettle, crystallizing the gel for 0.25-2 days at the temperatureof 100-180 DEG C, and carrying out suction filtration, washing and drying on the product to obtain the Omega zeolite molecular sieve raw powder. The Omega zeolite molecular sieve is rapidly synthesized under hydrothermal synthesis conditions by taking choline as a template agent, has the advantages of short synthesis period, environmental friendliness and low cost, and conforms to the target of green sustainable development.

Owner:INST OF APPLIED CHEM JIANGXI ACAD OF SCI

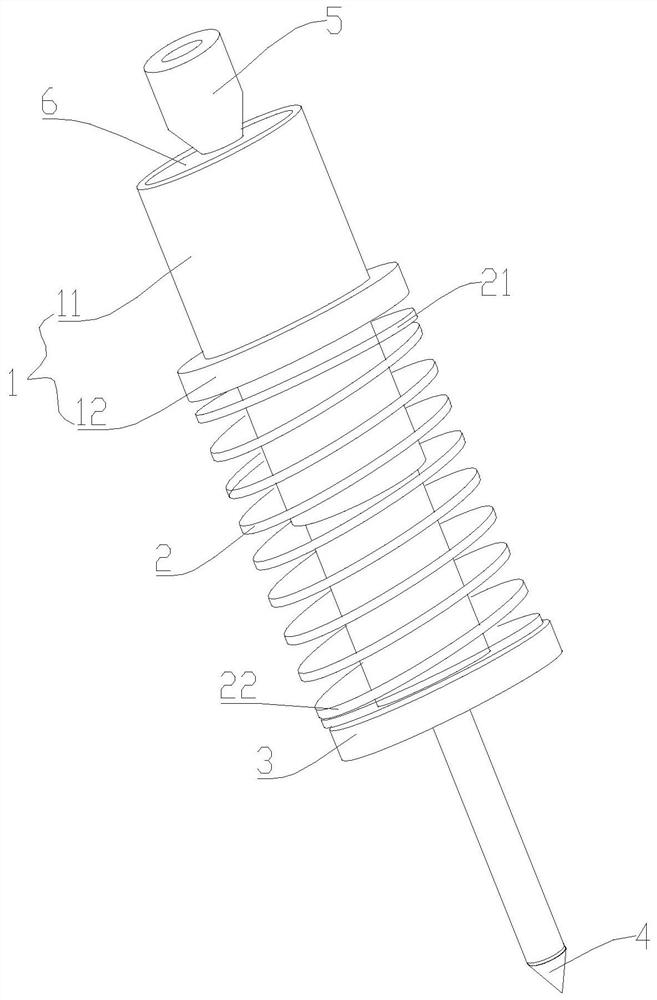

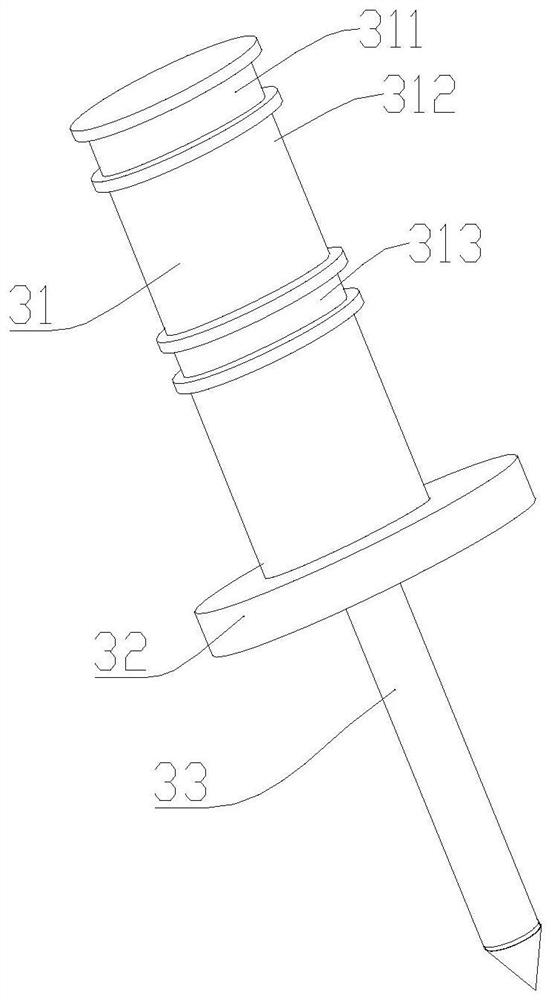

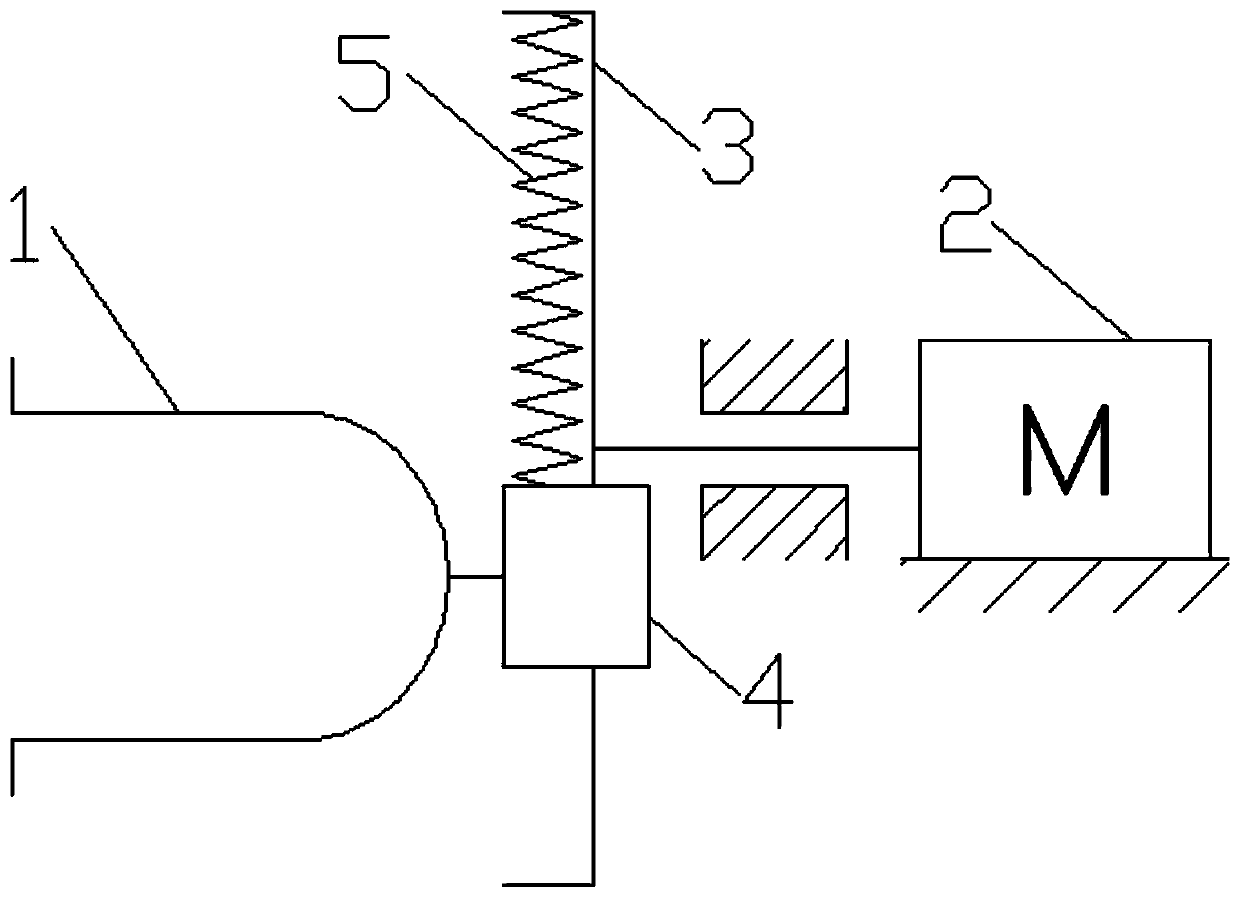

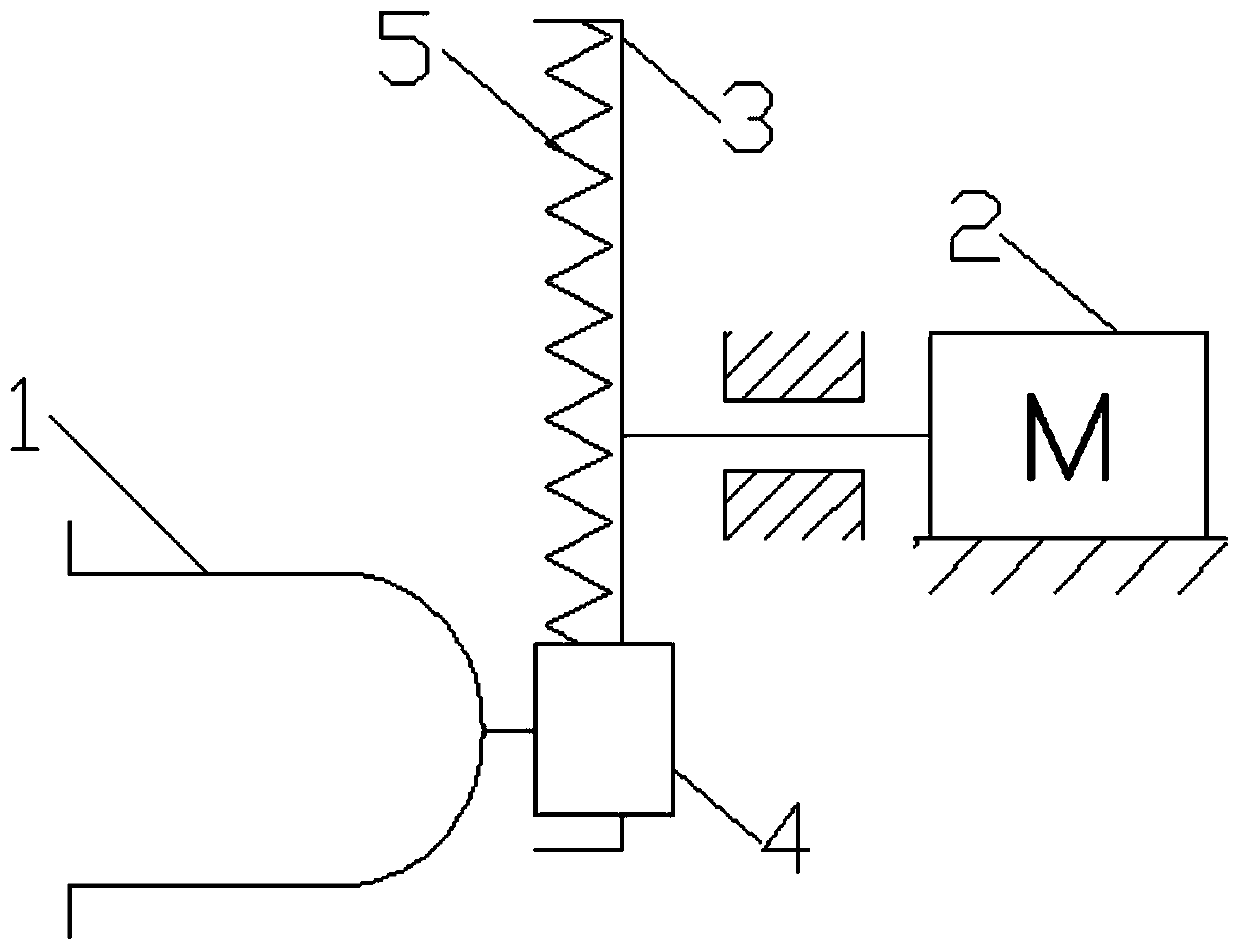

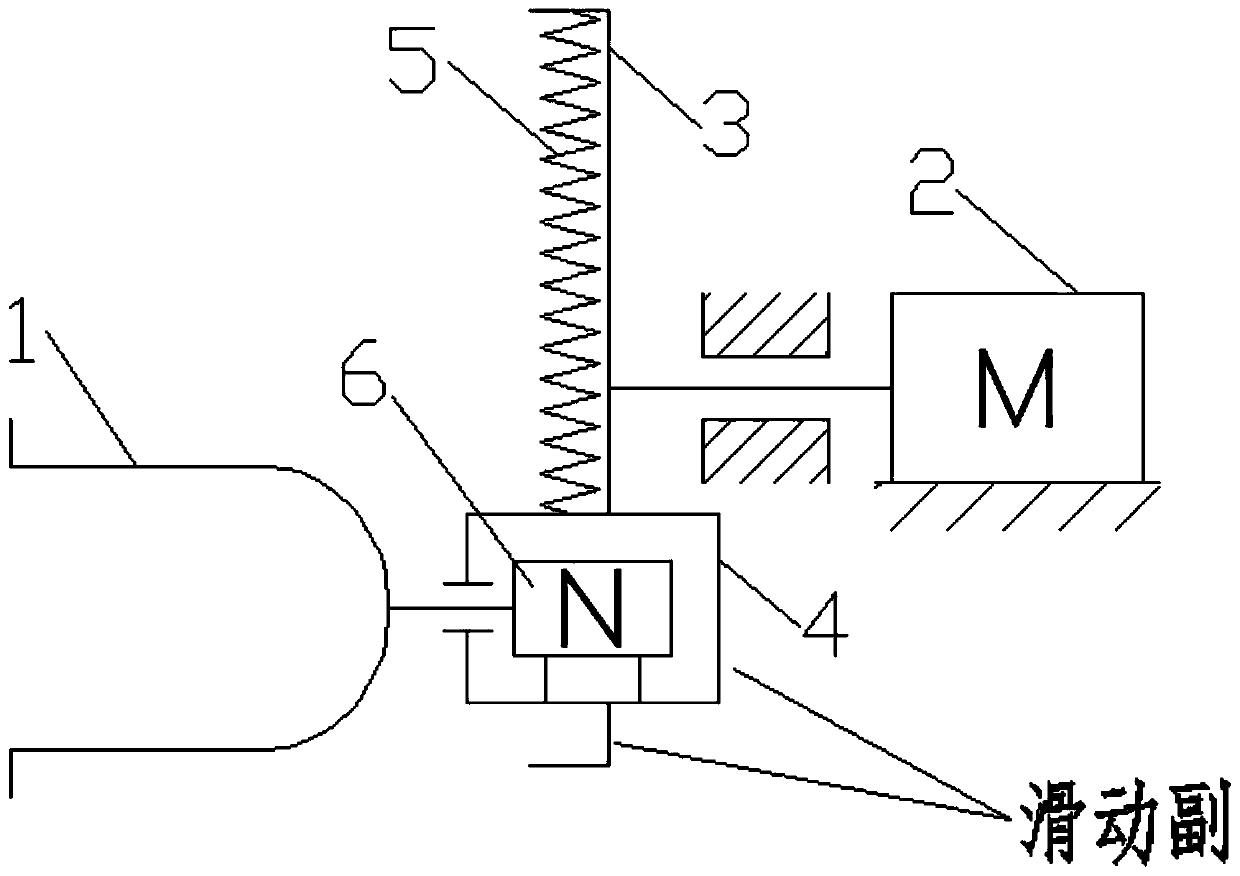

Reusable memory mud core

InactiveCN102773417AImprove breathabilityMeet the needs of rapid productionFoundry mouldsFoundry coresMemory effectShape-memory alloy

The invention provides a reusable memory mud core which is formed by special processing steps on the basis of the shape memory effect of memory alloy. The mud core structurally comprises a depoling rotating handle, a memory alloy spring, a locator and a cylindrical net material, wherein the depoling rotating handle is connected with the memory alloy spring, the memory alloy spring is twisted when the depoling rotating handle is rotated in the clockwise direction, and the surface area of the mud core is reduced to separate the memory mud core from a product. When the reusable memory mud core is in use, no harmful gas is generated, the ventilation property is good, and the requirements on mass and fast production are satisfied.

Owner:WUXI LIHU PRESSURIZE TECH CO LTD

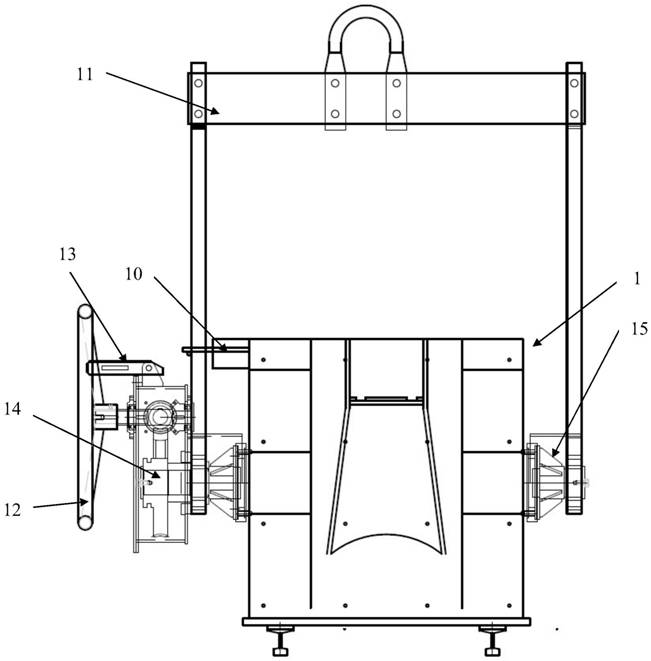

Eccentric type automatic cooking equipment and cooking system adopting same

PendingCN110338638AImprove cooking efficiencyUniform tasteCooking vessel supportCooking vessel constructionsControl systemFood material

The invention discloses eccentric type automatic cooking equipment and a cooking system adopting the same, and belongs to the field of cooking equipment. The eccentric type automatic cooking equipmentcan simulate the wok tossing effect of a chef, so that food can be better turned over, food materials can be uniformly heated, seasonings can be uniformly distributed, and automatic cooking of the food is realized. The eccentric type automatic cooking equipment comprises a cooking pot, an eccentric adjusting assembly, a heating device capable of heating the food in the cooking pot, and a controlsystem, wherein the eccentric adjusting assembly comprises a first driving device, an eccentric frame, a pot body supporting piece and a length adjusting piece. By designing the corresponding mechanisms, the cooking pot can realize eccentric rotation, autorotation and combination of the eccentric rotation and the autorotation, so that the food in the pot can be fully turned over and mixed, the food in the pot is uniformly heated, the seasonings are uniformly mixed, and the effect of automatic food cooking is achieved. The equipment is ingenious in concept, reasonable in design and relatively high in application value.

Owner:麦维文

Automatic bag cutting mechanism used for flexible intelligent bagging equipment

The invention discloses an automatic bag cutting mechanism used for flexible intelligent bagging equipment. The automatic bag cutting mechanism comprises a first feeding cylinder, a first fixed seat, a U-shaped plate, a second fixed seat and a connector, wherein one end of the first feeding cylinder is arranged on one surface of the U-shaped plate by virtue of the first fixed seat; the output end of the first feeding cylinder is a first piston rod, and a connecting plate is arranged at one end of the first piston rod by virtue of the connector; a second feeding cylinder is arranged on the connecting plate by virtue of the second fixed seat; the output end of the second feeding cylinder is a second piston rod, and a supporting plate is arranged at one end of the second piston rod; and a cutter is arranged on the upper end of the supporting plate. According to the invention, by designing the bag cutting mechanism, space is saved, and automatic production level is improved; and by applying the mechanism, time is shortened, and quick production requirement can be beneficially met.

Owner:ANHUI YOURFRIEND PULP MOLDING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com