Heat insulation pouring ladle with ladle lining push-out device

A technology for pushing out devices and pouring ladles, which is applied in the direction of casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems of long cycle of pouring ladles and the inability of heat preservation of pouring ladles to meet the process requirements, etc., to achieve increased speed and improved Insulation performance, to meet the effect of rapid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

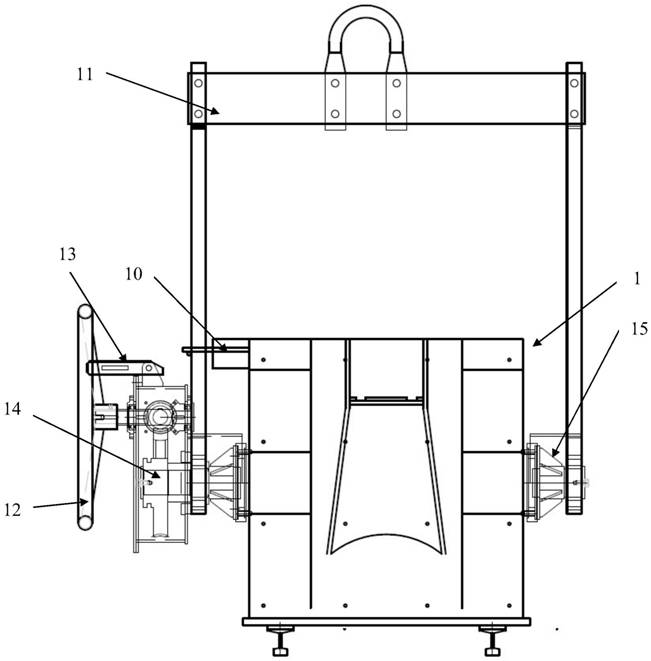

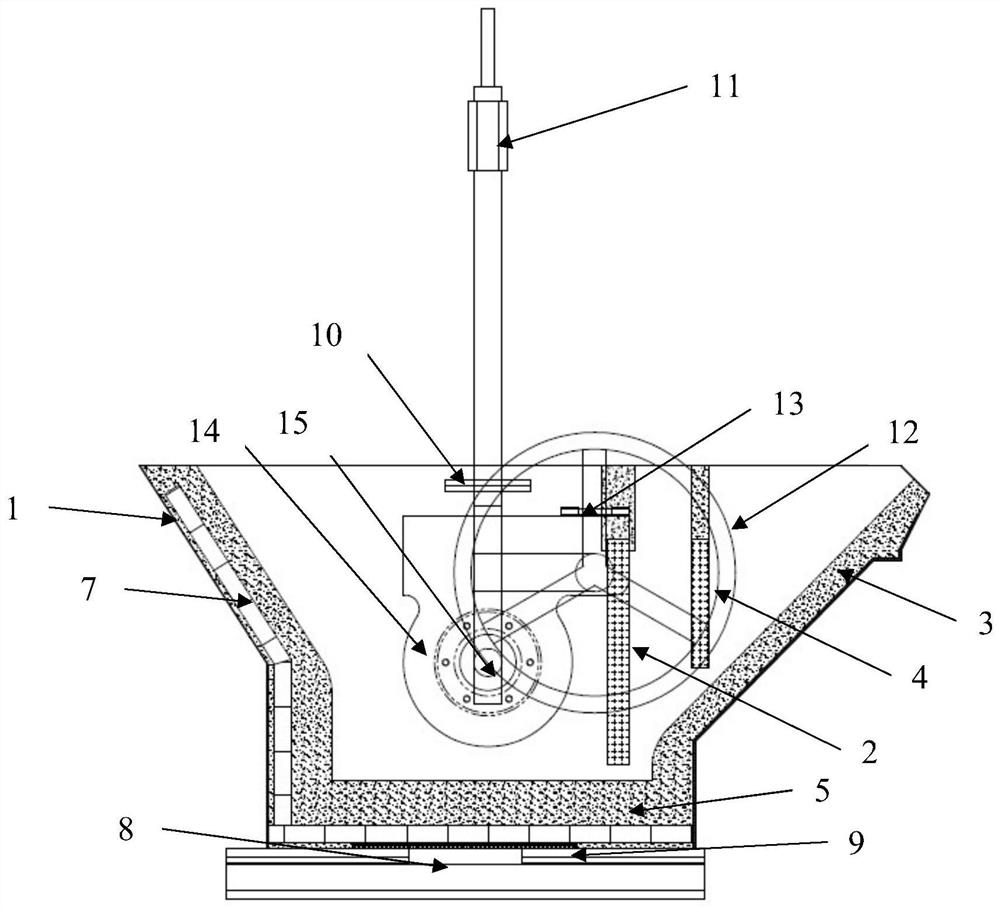

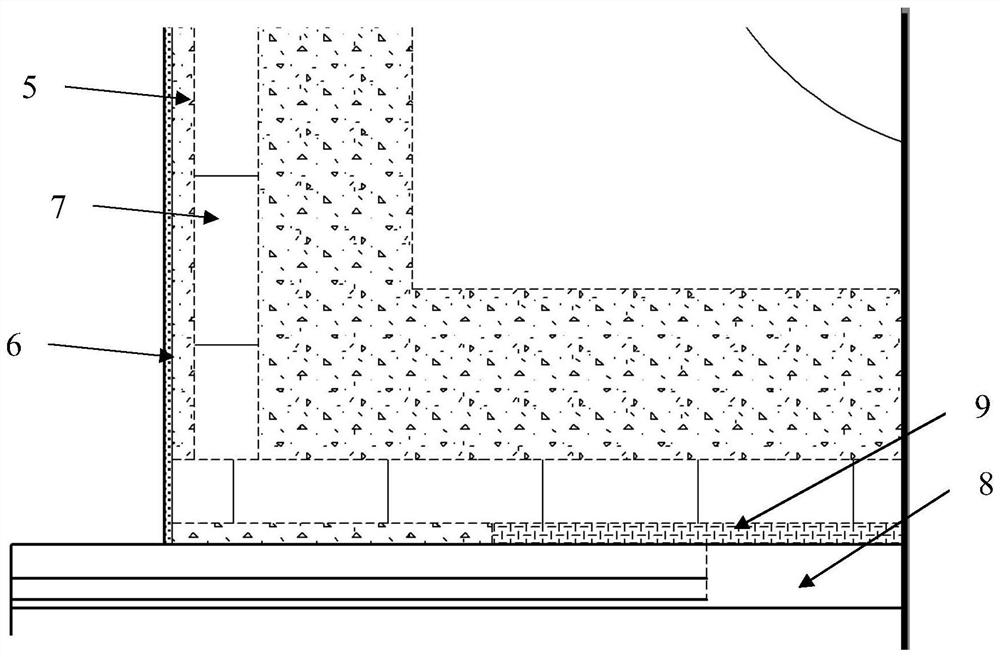

[0026] In order to better understand the purpose, structure and function of the present invention, a kind of thermal insulation pouring bag with a lining push-out device of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] Such as Figure 1-Figure 4 As shown, the present invention includes: a cladding 1, a cladding beam 11 arranged on the cladding 1, wherein, both sides of the cladding 1 are respectively provided with a cladding shaft 15 in a shaft-hole connection mode, and a cladding shaft 15 is adopted on the cladding shaft 15. The shaft hole connection mode is respectively equipped with a vertical pole, and a cladding beam 11 is installed between the upper ends of the two poles. A cladding buckle 10 is arranged on the pole on one side of the cladding beam 11, and a cladding buckle 10 on the side of the cladding buckle 10 is provided. The shell shaft 15 is connected with the reducer 14, and the reducer 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com