Reusable memory mud core

A technology of memory and core, which is applied in the field of aluminum alloy casting, can solve the problems of gas generation, exhaust cooling rate that cannot meet the requirements of mass production, power consumption of core, and generation of harmful gases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

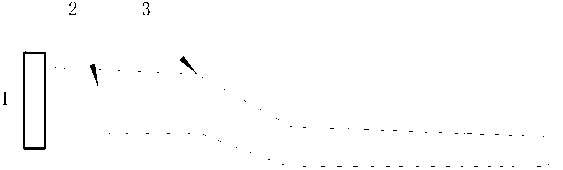

[0008] figure 1 It includes a core-removing knob (1), a memory alloy skeleton (2), and a memory alloy wire woven tubular mesh material (3). The core-removing knob (1) is placed on the opening end of the memory alloy spring (2); the memory alloy spring (2) is made of memory alloy wire; Mesh material (3).

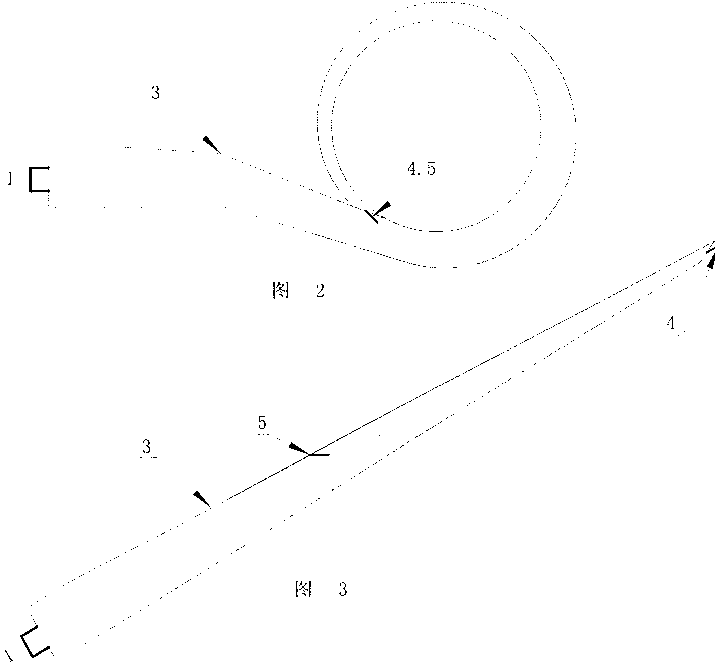

[0009] figure 2 The diagrams (4) and (5) in the figure are the positioning devices of the memory core, the positioning hole (4) is arranged on the memory alloy spring (2), and the positioning nail (5) is placed on the top of the memory alloy spring (2), The positioning nail (4) cooperates with the positioning hole (5) to restore the memory shape through drying and heating of the paint, and the memory shape of the memory core meets the technical requirements of casting the compressor casing.

[0010] image 3 It is the shape that can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com