Heat-resistant saline-water-erosion-resistant chloroprene spray adhesive and preparation method and application thereof

A technology of neoprene spray glue and salt water resistance, which is applied in the direction of chloroprene adhesives, adhesives, halogen rubber derivative adhesives, etc., and can solve the problem of poor storage stability of neoprene spray glue, not resistant to salt water erosion, Uneven spraying and other problems, to meet the needs of rapid production, excellent salt water resistance, good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In the preparation process of tert-butylphenol-formaldehyde resin, the molecular weight and length of the obtained tert-butylphenol-formaldehyde resin are moderate through melting and reacting in alkaline solution, and the small molecules in the reaction are removed by washing process, with high purity, high viscosity and high softening point, which can Improve the heat resistance of spray glue to meet the performance requirements of ocean-going containers for salt water corrosion resistance and high temperature resistance.

[0038] The present invention also includes a preparation method of heat-resistant, salt-water corrosion-resistant chloroprene spray glue, comprising the following steps:

[0039] (1) In parts by weight, 120-140 parts of chloroprene rubber are masticated in an open mill, and 4-6 parts of active magnesium oxide, 12-15 parts of nano-active zinc oxide, and 0.5-1 part of accelerator D are added to it , mixing 1-1.5 parts of sulfur with 5-8 parts of phen...

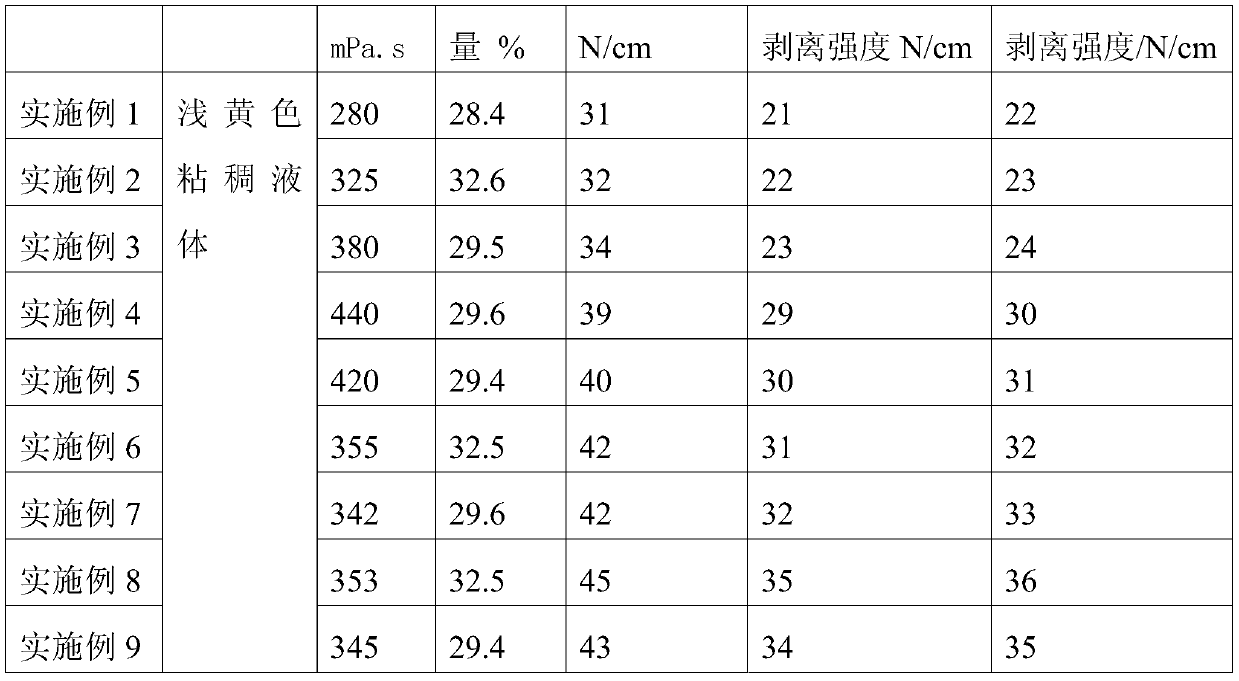

Embodiment 1

[0044] A heat-resistant and salt-water corrosion-resistant chloroprene spray glue, which is composed of the following raw materials: 120kg chloroprene rubber, 10kg chlorinated rubber, 90kg phenolic resin, 4kg activated magnesium oxide, 12kg nano-active zinc oxide, and 2kg antioxidant , accelerator D0.5kg, sulfur 1kg, methyl acetate 220kg, solvent naphtha 220kg, methylcyclohexane 230kg, diethylene glycol butyl ether 15kg and coupling agent 1kg.

Embodiment 2

[0046] A heat-resistant and salt-water corrosion-resistant chloroprene spray glue, which is composed of the following raw materials: 140kg chloroprene rubber, 25kg chlorinated rubber, 120kg phenolic resin, 6kg activated magnesium oxide, 15kg nano-active zinc oxide, and 3kg antioxidant , accelerator D1kg, sulfur 1.5kg, methyl acetate 240kg, solvent naphtha 250kg, methylcyclohexane 260kg, diethylene glycol butyl ether 20kg and coupling agent 2kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com