Column tube single face square opening punch forming processing method

A processing method and stamping forming technology, which is applied in the field of cylindrical tube parts processing, can solve the problems of low production efficiency, uneven R, rough processing surface, etc., and achieve the effect of high processing efficiency, small hole deformation and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is further described as follows:

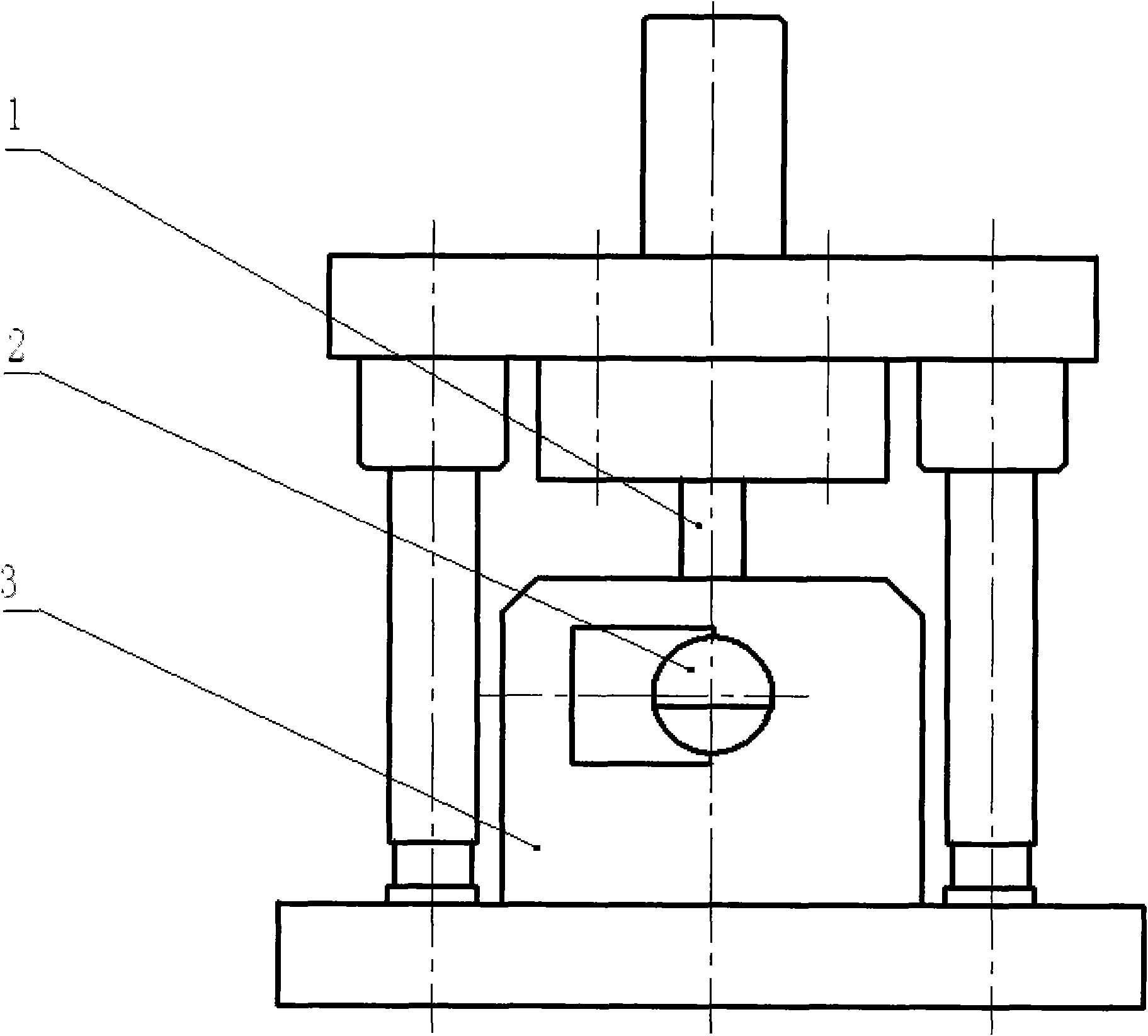

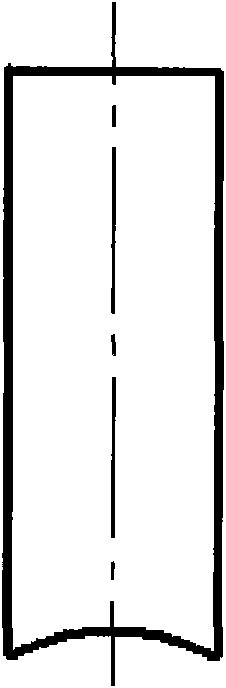

[0020] The present invention uses a special punching die to process a square hole on one side of the column tube. The special punching die is composed of special components such as an inner R-shaped cutting edge punch, a replaceable wedge-type die, a wedge-type unloading insert, and a fixed sleeve seat. The main components such as the inner R-shaped cutting punch, the interchangeable wedge-type die tilt, and the fixed sleeve seat with wedge-type unloading insert have the following characteristics:

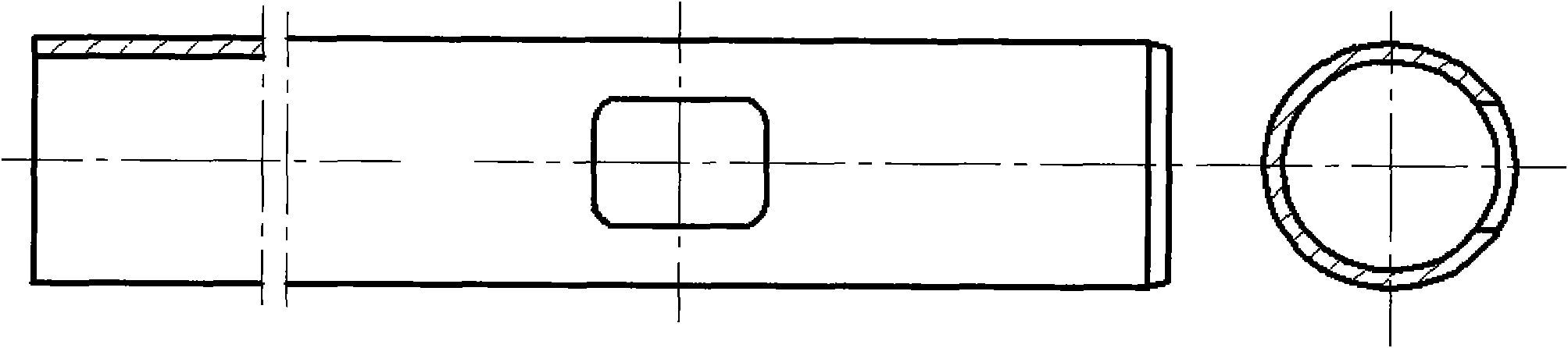

[0021] image 3 It is an inner R-shaped cutting punch, and the material of the punch is Cr12MoV heat-treated at 54-58HRC. The R control inside the punch must be consistent with the R outside the column tube, otherwise the shearing force on the tube column will be inconsistent and cause deformation. The orifice collapses; due to the springback of the keyhole size after p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com