Fermentation bin for disposal of organic wastes

A technology for organic waste and waste treatment, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of large power consumption, slow heating speed, long processing time, etc., and achieve rapid heating efficiency improvement, Preheating time is shortened to meet the effect of rapid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

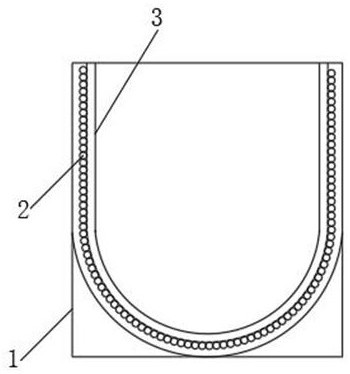

[0016] like Figure 1-4 It is a structural schematic diagram of the present invention, a fermentation bin for organic waste treatment, including an outer frame 1, an inner layer 3 is welded inside the outer frame 1, and a heating device 2 is wrapped on the outer side of the inner layer 3.

[0017] When the fermentation bin for organic waste treatment is in use, the heating device 2 is wrapped on the outside of the inner layer 3, and the heating is started after it is completely wrapped, and the heating effect is better, so that it can meet the heating demand.

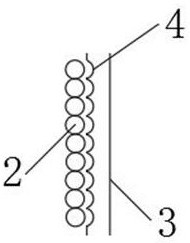

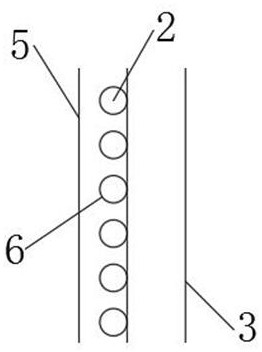

[0018] According to another embodiment of the present invention, it further includes that grooves 4 are arranged on the outside of the inner layer 3 , and the heating device 2 is embedded in the grooves 4 .

[0019] The groove 4 of the inner layer 3 can wrap the heating device 2 embedded, so that the heating device 2 can better contact the inner layer 3, increase the contact area of the heating device 2, and better im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com