Method for synthesizing Omega zeolite molecular sieve

A zeolite molecular sieve, aluminum source technology, applied in the direction of crystalline aluminosilicate zeolite, ZSM-4 type crystalline aluminosilicate zeolite, nanotechnology, etc., can solve the problem of non-green environmental protection, unfavorable Omega zeolite catalyst industrial production, synthesis cycle It can achieve the effect of simple and reliable preparation method, good adsorption and catalytic ability, good crystallinity and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

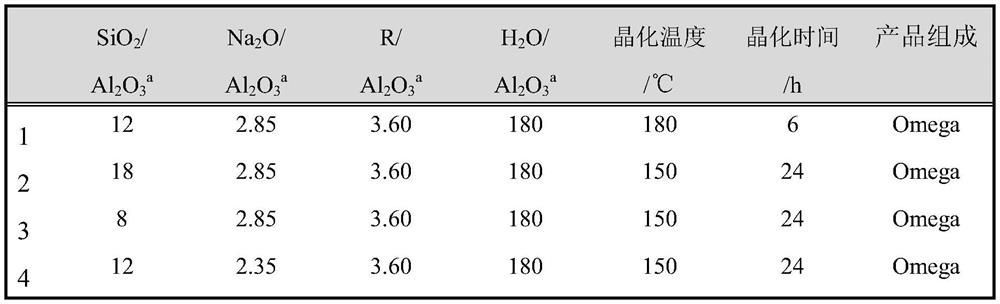

[0017] Embodiment 1: the preparation of Omega zeolite sample

[0018] First, dissolve 0.76g of sodium hydroxide in 8.9g of deionized water, add 0.486g of pseudoboehmite to it, after the solution is clarified, add 2.4g of fine silica gel, continue to stir, then slowly add 3.3g of choline and stir to a uniform gel; add the reaction raw materials into a polytetrafluoroethylene stainless steel reactor, and crystallize at 180°C for 0.25 days to complete the crystallization, cool at room temperature, wash with deionized water until neutral, and filter the product under suction at 100°C The product was obtained after air drying.

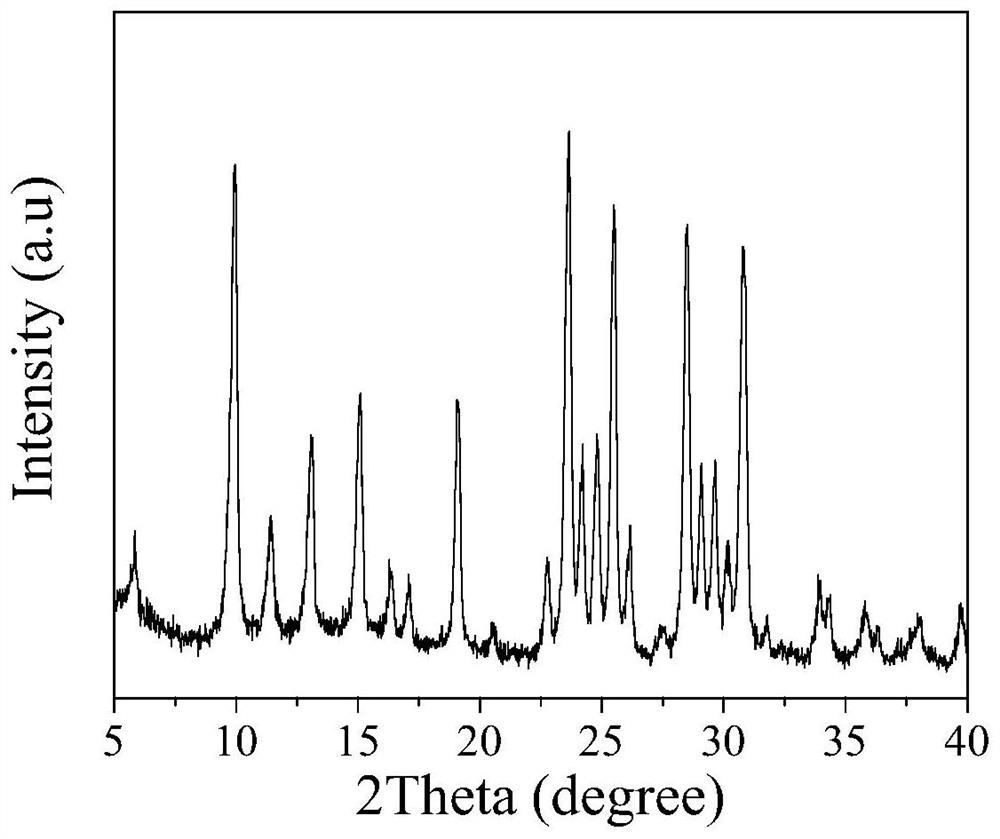

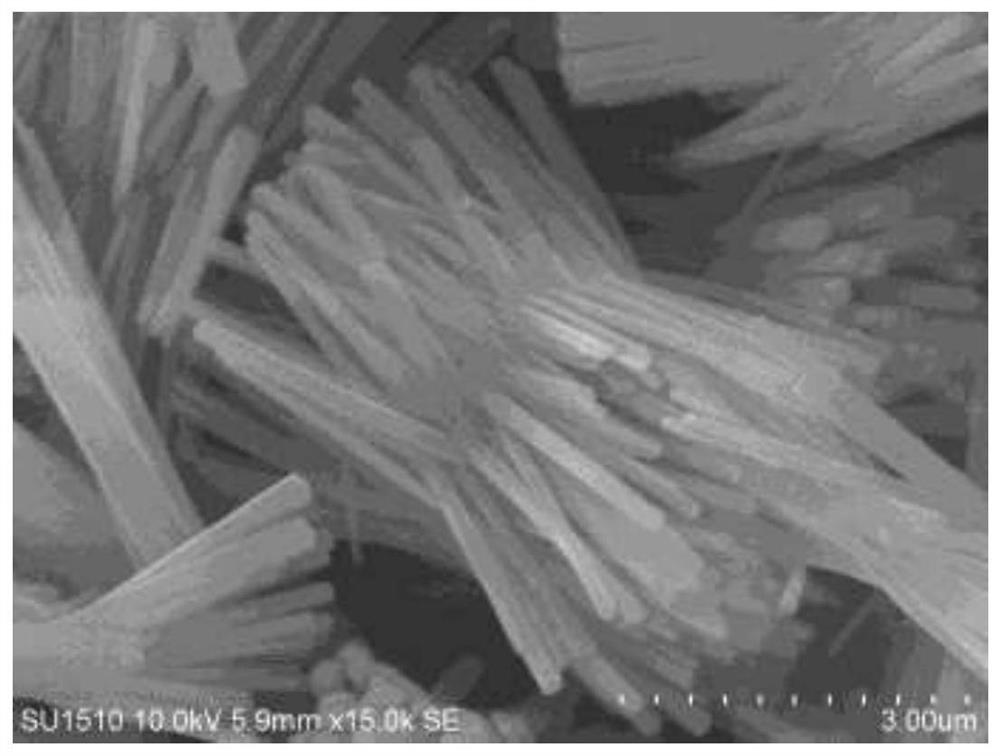

[0019] attached figure 1 It is the X-ray diffraction pattern (XRD) of the synthesized product, and its structure is Omega zeolite molecular sieve through X-ray diffraction analysis. attached figure 2 It is a scanning electron micrograph (SEM) of the synthesized sample, and it can be seen that the synthesized product presents a nanorod cluster morphology...

Embodiment 2

[0020] Embodiment 2: the preparation of Omega zeolite sample

[0021] First, dissolve 0.76g of sodium hydroxide in 8.9g of deionized water, add 0.486g of pseudoboehmite to it, after the solution is clarified, add 3.6g of fine silica gel, continue to stir, then slowly add 3.3g of choline and stir to a uniform gel; add the reaction raw materials into a polytetrafluoroethylene stainless steel reactor, and crystallize at 150°C for 1 day to complete the crystallization, cool at room temperature, wash with deionized water until neutral, and filter the product with suction and dry at 100°C The product was obtained after air drying.

Embodiment 3

[0022] Embodiment 3: the preparation of Omega zeolite sample

[0023] First, dissolve 0.76g of sodium hydroxide in 8.9g of deionized water, add 0.486g of pseudoboehmite to it, after the solution is clarified, add 1.6g of fine silica gel, continue to stir, then slowly add 3.3g of choline and stir to a uniform gel; add the reaction raw materials into a polytetrafluoroethylene stainless steel reactor, and crystallize at 150°C for 1 day to complete the crystallization, cool at room temperature, wash with deionized water until neutral, and filter the product with suction and dry at 100°C The product was obtained after air drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com