Device for preventing spark fly and dust collection for cutter

A technology of dust collecting device and cutting machine, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc. Fire and other problems, to achieve good application effect, reduce hidden dangers in safety production, and prevent the occurrence of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

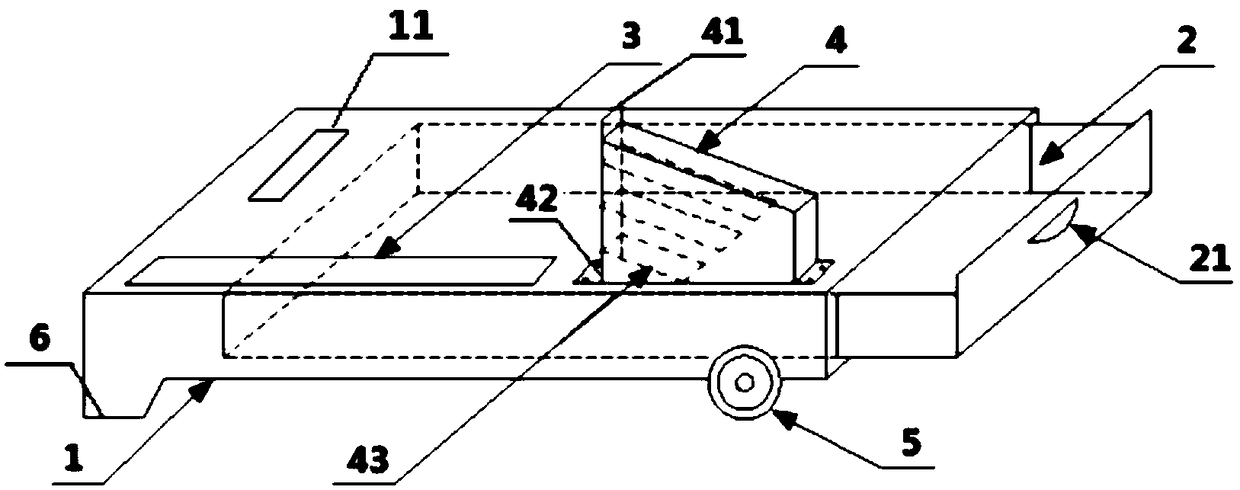

[0020] combined with figure 1 The technical scheme of the present invention will be further described.

[0021] Such as figure 1 As shown, the present invention provides a dust collection device for preventing sparks from cutting machines, the device includes a base 1, and the upper surface of the base is provided with a window 11 made of transparent material, which is convenient for observing the state of the dust collection box. One side of the base is provided with a drawer-type dust collection box 2; a handle 21 can be provided outside the dust collection box for the convenience of pulling. The surface of the base 1 is respectively provided with a cutting piece incision 3 and an extinguishing shield 4 . The bottom 1 of the base is provided with wheels 5 . In the present invention, the base 1 is provided with a pair of wheels on one side of the dust box 2 , and the other side is provided with legs 6 . This design is convenient and fast to move through the wheels and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com