A fixed-width cutting device for film packaging sticking line production

A technology of film packaging and cutting knives, which is applied in metal processing and other directions, can solve the problems of unsatisfactory fast production and low cutting efficiency, and achieve the effect of fast and automatic adjustment of cutting width, satisfying fast production and improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

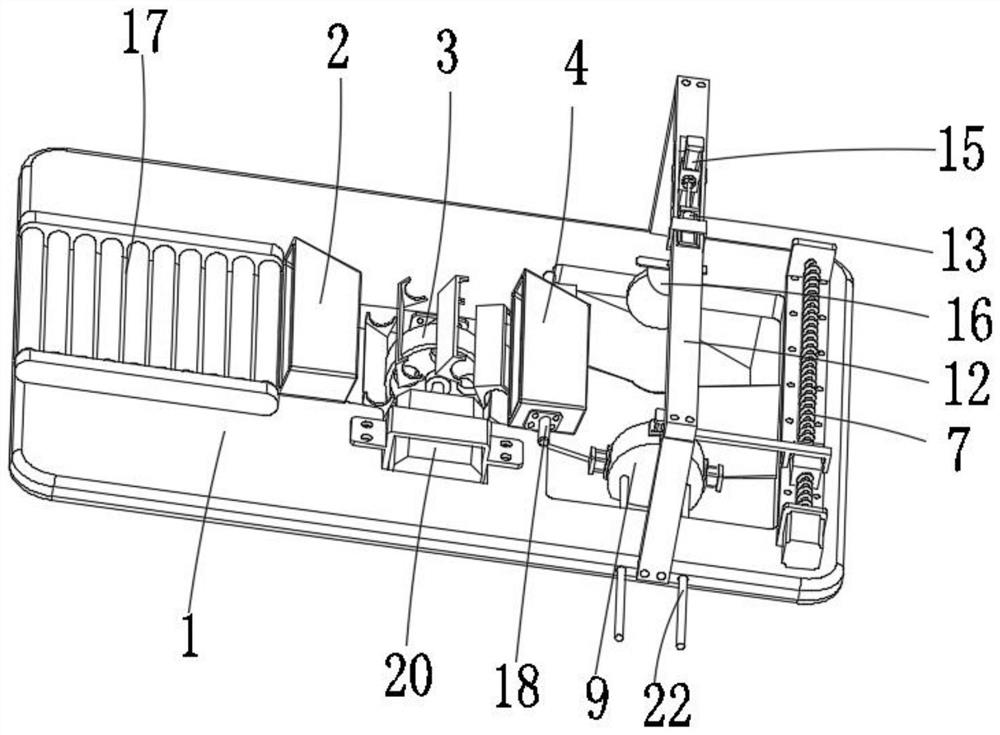

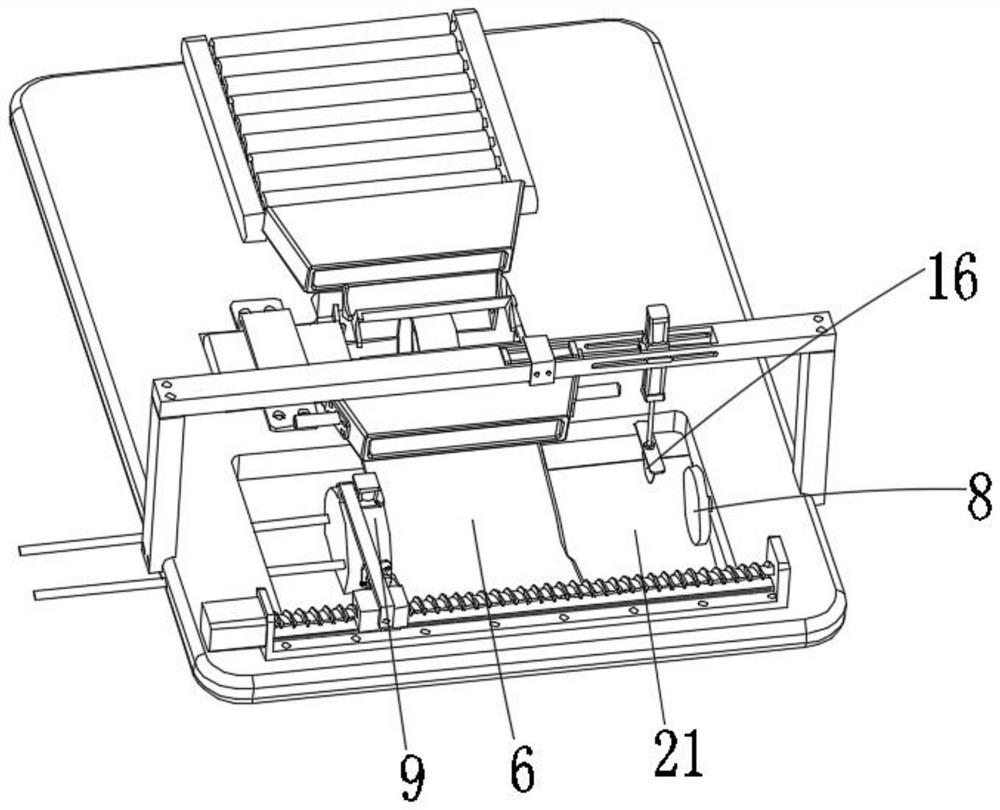

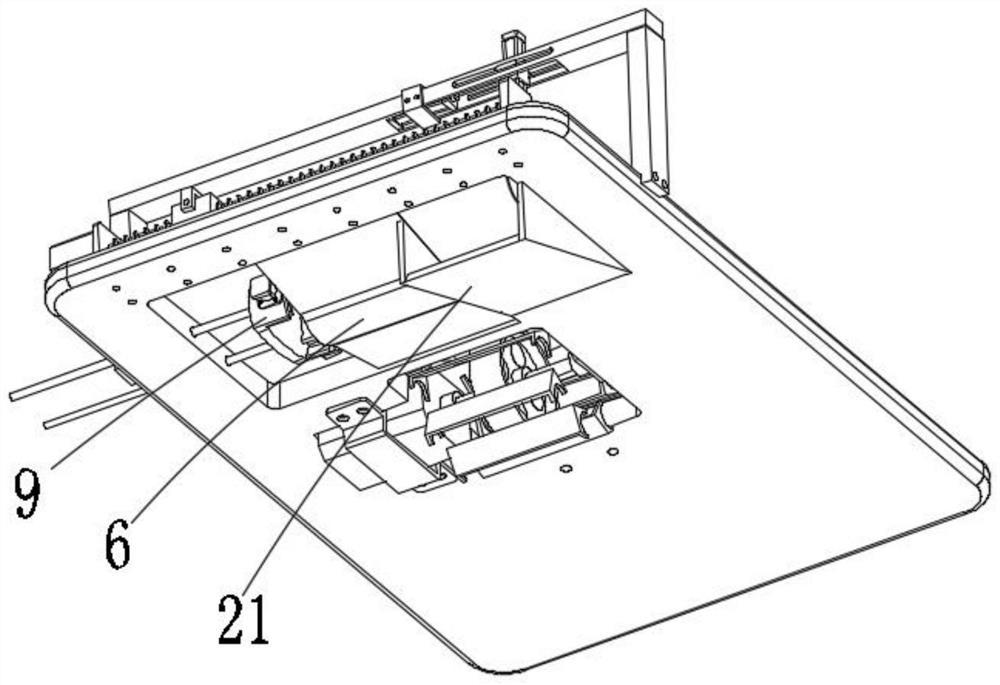

[0036] A kind of fixed-width cutting device for film packaging sticking line production in this embodiment, refer to Figure 1-9 : Including workbench 1, workbench 1 is provided with conveying member, group conveying member and fixed-width cutting member sequentially from left to right, and group conveying member includes the trough that is arranged obliquely on the upper side of workbench 1 and is located on the right side of conveying member Body 2, the runner 3 that rotates in the middle of the workbench 1 and is located on the right side of the inlet body 2, and the outlet body 4 that is obliquely arranged on the upper side of the workbench 1 and is located on the right side of the runner 3, and the outer side of the runner 3 is provided with Several groups of inclined frames 5 protrude from the outer surface of the runner 3 , and several groups of inclined frames 5 form a circular array around the rotation axis of the runner 3 .

[0037] The fixed-width slitting member in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com