Sponge cutting device for massage chair production

A massage chair and sponge technology, applied in metal processing and other directions, can solve the problems of inability to meet the rapid production and low efficiency of enterprises, and achieve the effect of improving cutting efficiency, reducing labor intensity and continuous cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

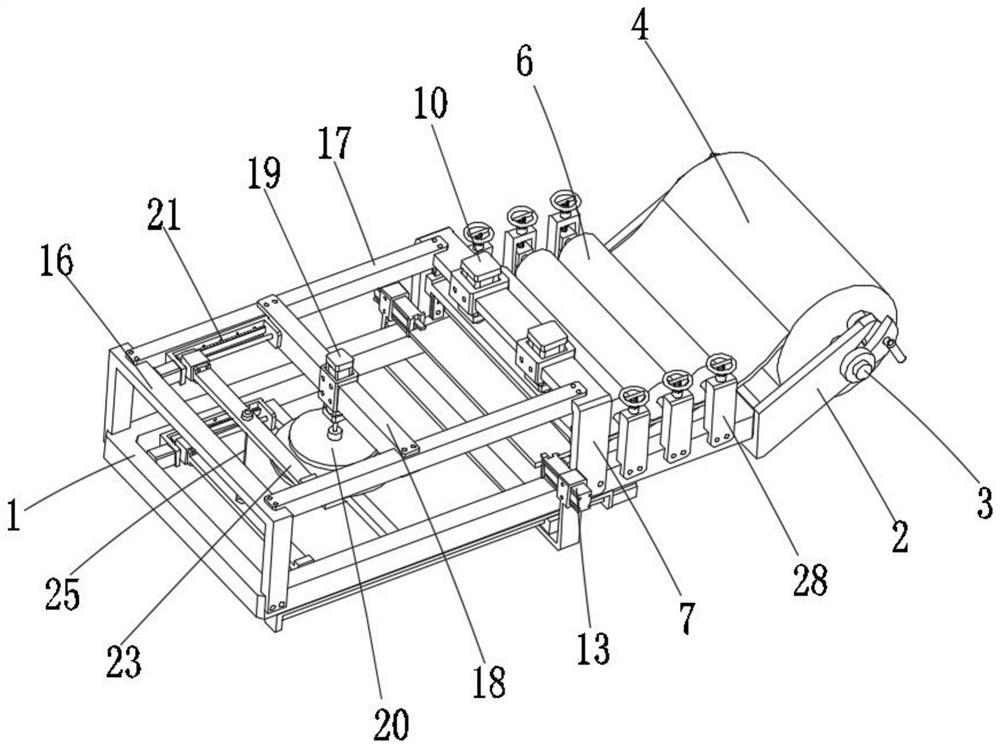

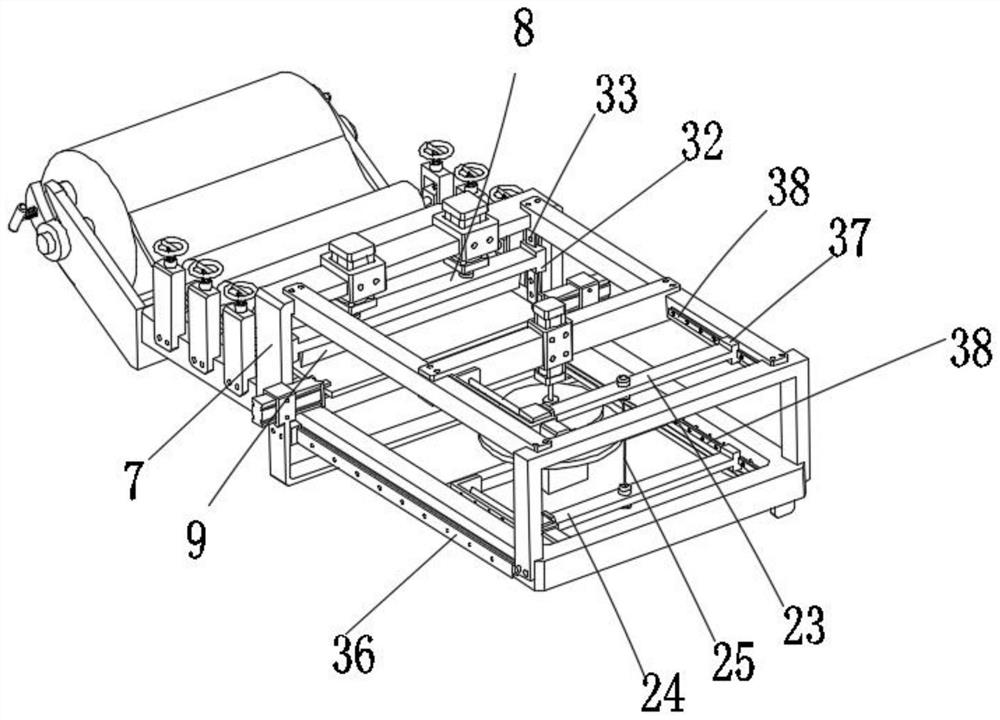

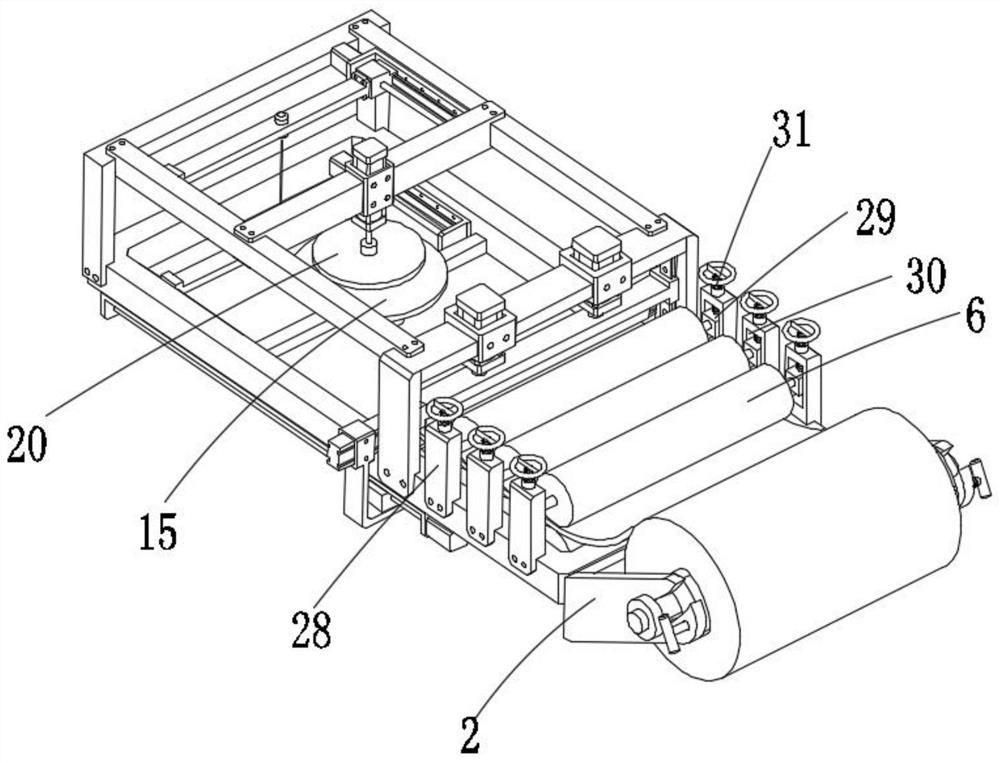

[0034] A kind of sponge cutting device for massaging chair production of the present embodiment, refer to Figure 1-7: Including a rectangular working frame 1, the right side of the rectangular working frame 1 is fixedly connected with an unwinding frame 2, and the unwinding frame 2 is equipped with a sponge roll 4 wound by a reel 3, and the right part of the rectangular working frame 1 is provided with several groups through the lower The lower pressing wheel 5 connected by the rotation of the wheel shaft, the upper side of the right part of the rectangular working frame 1 is provided with several groups of upper pressing wheels 6 connected by the rotation of the adjusting member, and the middle part of the rectangular working frame 1 is provided with a cutter member, which includes a fixed connection The right concave frame 7 on the upper side of the middle part of the rectangular working frame 1, the cutting knife frame 8 sliding in the right concave frame 7, the cutting kni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com