Liquid composite high-intensity sweeter and preparation method thereof

A high-power sweetener and sweetener technology, applied in the field of food additives, can solve problems such as unfavorable enterprises' clean production, difficulty in mixing uniformly, and affecting product quality, so as to improve synergy, ensure food safety, and be free of particles residual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

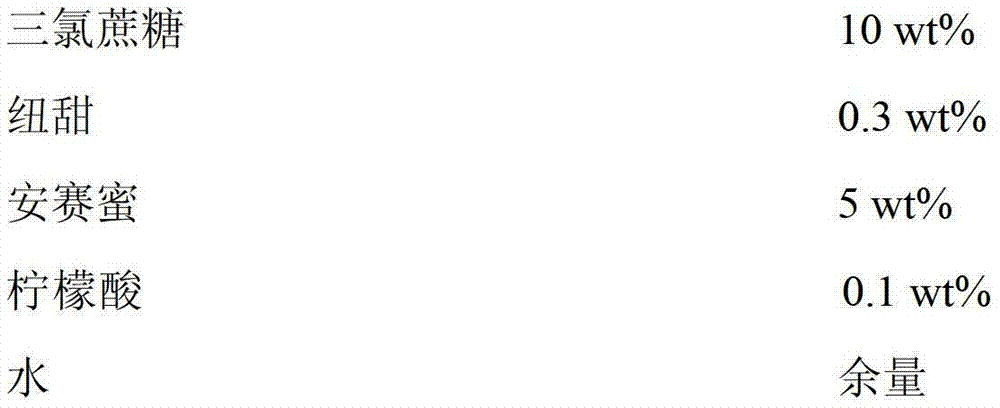

[0025] 1. The composition of the liquid compound high-power sweetener of the present embodiment is as follows:

[0026]

[0027] 2. The preparation method of the liquid compound high-power sweetener in this embodiment is as follows:

[0028] (1) Dissolving and mixing sucralose, neotame and acesulfame K in a solvent composed of citric acid and water to obtain a composite system, the pH of which is 4.2;

[0029] (2) The composite system is subjected to high-temperature sterilization treatment at a temperature of 100°C, and the sterilization time is 10s;

[0030] (3) After the compound system is sterilized at high temperature, lower the temperature to 25° C. for 300 s to obtain a liquid compound high-intensity sweetener product.

Embodiment 2

[0032] 1. The composition of the liquid compound high-power sweetener of the present embodiment is as follows:

[0033]

[0034] 2. The preparation method of the liquid compound high-power sweetener in this embodiment is as follows:

[0035] (1) After mixing neotame and acesulfame potassium, they are dissolved and mixed in a solvent composed of propylene glycol, sorbic acid, potassium sorbate and water to obtain a composite system, the pH value of which is 4.7;

[0036] (2) The composite system is subjected to high-temperature sterilization treatment at a temperature of 130°C, and the sterilization time is 5s;

[0037] (3) After the compound system is sterilized at high temperature, the temperature is lowered to 25° C. and the temperature is lowered for 250 s to obtain a liquid compound high-intensity sweetener product.

Embodiment 3

[0039] 1. The composition of the liquid compound high-power sweetener of the present embodiment is as follows:

[0040]

[0041] 2. The preparation method of the liquid compound high-power sweetener in this embodiment is as follows:

[0042] (1) Dissolving and mixing sucralose and acesulfame potassium in a solvent composed of lactic acid, sodium benzoate and water to obtain a composite system, the pH of which is 5.5;

[0043] (2) The composite system is subjected to high-temperature sterilization treatment at a temperature of 120°C, and the sterilization time is 10s;

[0044] (3) After the compound system is sterilized at high temperature, the temperature is lowered to room temperature for 360 seconds to obtain a liquid compound high-intensity sweetener product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com