Special modified recycled polyethylene material for cables and preparation method of special modified recycled polyethylene material

A technology of recycled polyethylene and special materials, applied in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of high production cost, raw materials and cost pressure, and achieve the effect of reducing production cost, reducing investment and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

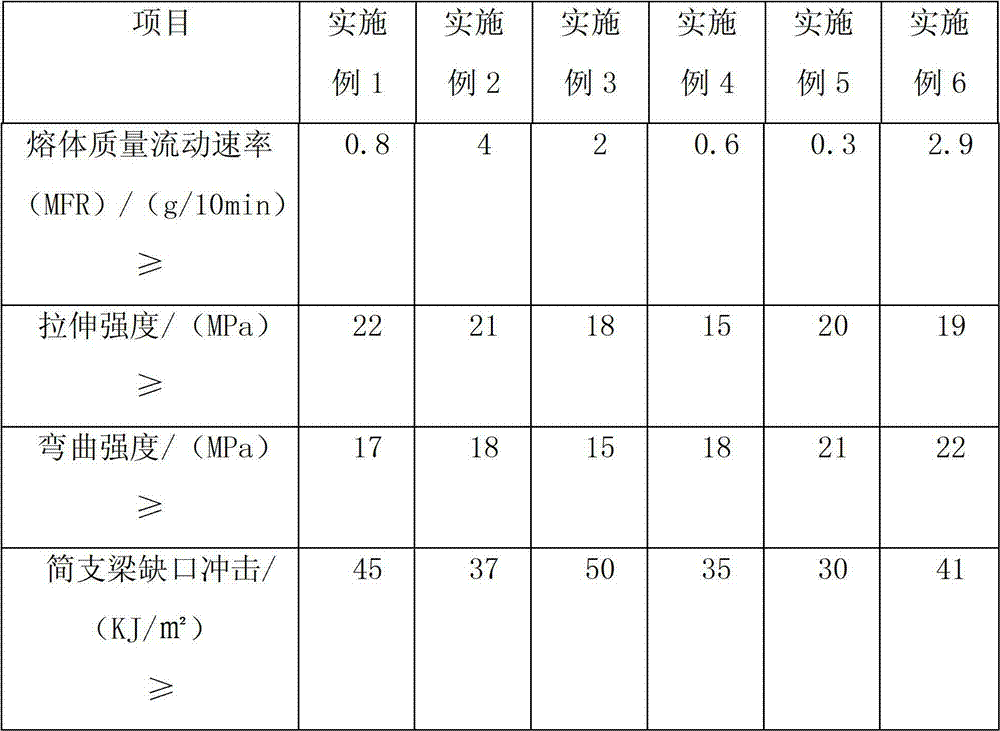

Embodiment 1

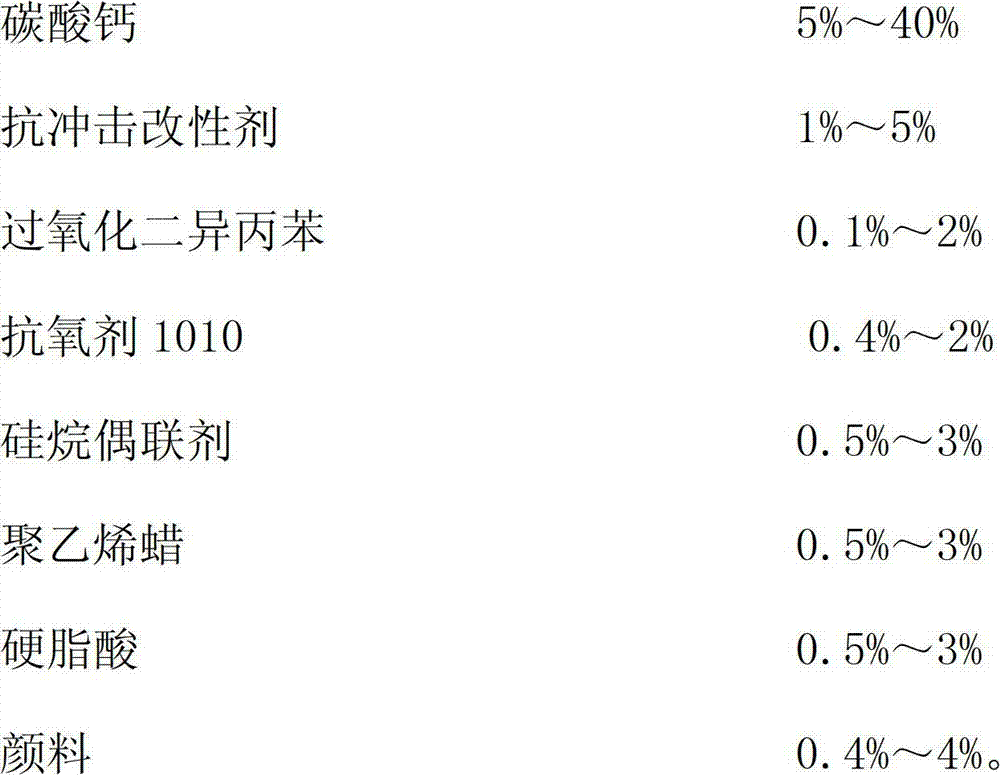

[0025] Special materials for modified recycled polyethylene pipes and pipe fittings, mainly composed of the following substances in weight percentage:

[0026] 7% polyethylene, 33% recycled polyethylene, 10% toughening agent, 20% talc, 2500 mesh 23% calcium carbonate, 1% impact modifier, 0.1% diiso peroxide Propylene, 0.4% antioxidant 1010, 0.5% silane coupling agent, 0.5% polyethylene wax, 2.5% calcium stearate, 2% pigment.

[0027] The specific preparation method is as follows:

[0028] Firstly, the waste polyethylene is crushed, washed, dried, and homogenized to obtain recycled polyethylene. In order to avoid other impurities mixed in the waste polyethylene from affecting it, a blower is also used to blow out other light items mixed in the waste polyethylene during the drying process, and the light items are plastic labels etc.

[0029] The above-mentioned substances are passed into the batching machine at the above-mentioned ratio through the batching machine, and they ...

Embodiment 2

[0031] The difference between this embodiment and Example 1 is that the percentage content of each component is different, and the percentage content of each component is as follows in the present embodiment:

[0032] 25% polyethylene, 15% recycled polyethylene, 20% toughener, 5% talc, 2500 mesh 15% calcium carbonate, 3% impact modifier, 2% diisoperoxide Propylene, 2% antioxidant 1010, 3% silane coupling agent, 3% polyethylene wax, 3% calcium stearate, 4% pigment.

Embodiment 3

[0034] The difference between this embodiment and Example 1 is that the percentage content of each component is different, and the percentage content of each component in the present embodiment is as follows:

[0035] 7% polyethylene, 70% recycled polyethylene, 5% toughening agent, 5% talc, 2500 mesh 5% calcium carbonate, 5% impact modifier, 0.4% diiso peroxide Propylene, 0.6% antioxidant 1010, 0.5% silane coupling agent, 0.6% polyethylene wax, 0.5% calcium stearate, 0.4% pigment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com