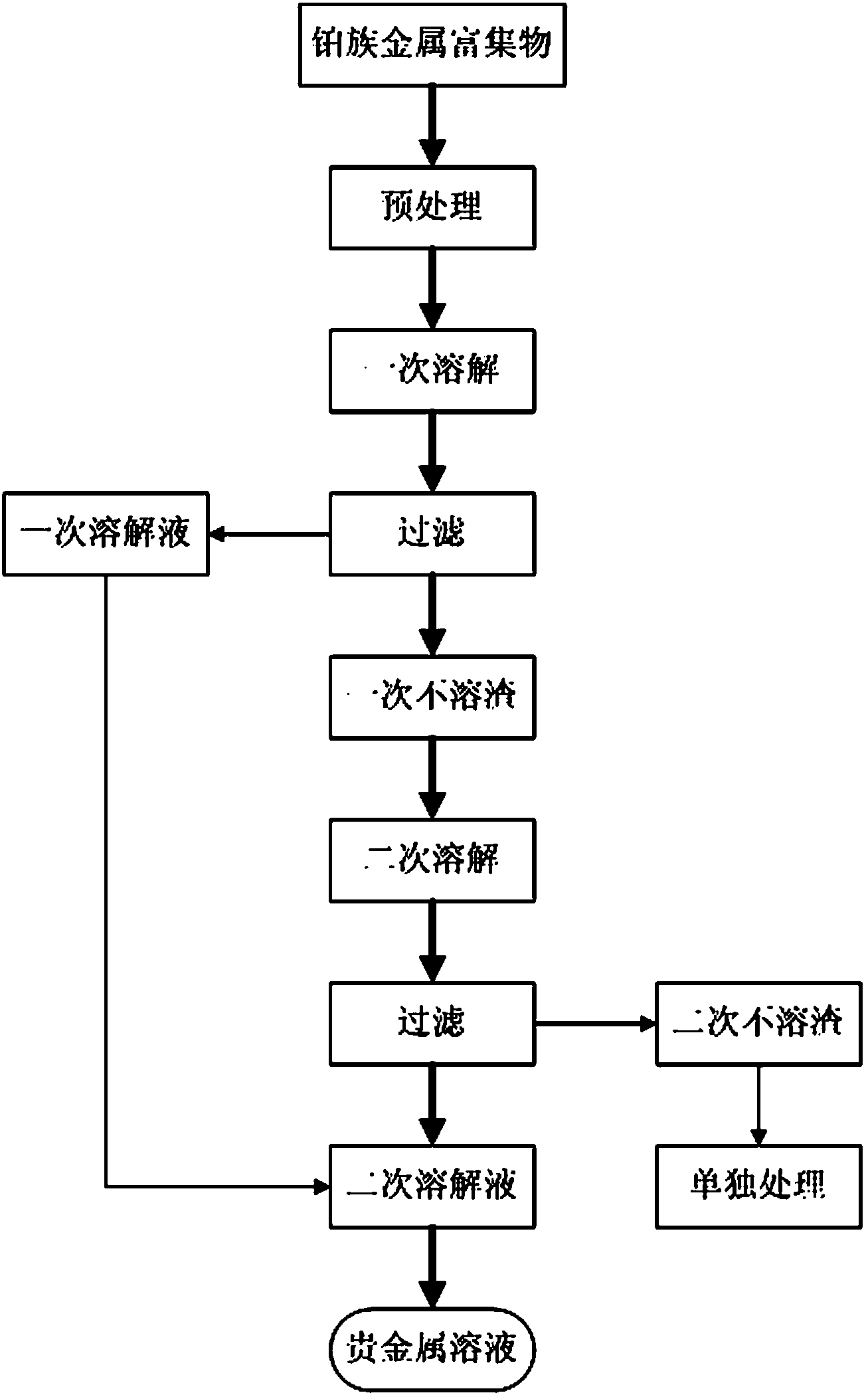

Method for dissolving platinum group metals in automobile spent catalyst enrichment

A technology of invalid catalysts and platinum group metals, which is applied in the direction of improving process efficiency, can solve the problems of low dissolution efficiency of platinum group metals, shorten the process flow, and consume large reagents, achieve significant environmental and economic benefits, and shorten the process flow , the effect of simplifying the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 The contents of platinum group metals in the enrichment of an automobile exhausted catalyst are (g), Pt661.13, Pd2217.63, Rh349.48, ∑PGMs: 3228.23, and the enrichment is calculated according to the solid-liquid ratio (S , L)=1:1~1:4 Add 8mol / L hydrochloric acid, heat to 70~80℃, add 10%~30%H dropwise 2 O 2 solution, control the dropping rate of 7-8L / h, and heat the reaction for 2-3h. After 2 times of dissolution, sampling and analysis: the dissolution rate of platinum is 99.80%, the dissolution rate of palladium is 99.40%, the dissolution rate of rhodium is 98.98%, and the total dissolution rate of platinum group metals is 99.57%.

Embodiment 2

[0022] Example 2 The contents of platinum group metals in the concentrate of an automobile spent catalyst are (g), Pt10109.0, Pd3325.40, Rh475.30, ∑PGMs: 4819.70, respectively. Add 10mol / L hydrochloric acid to the enriched material according to the solid-liquid ratio (S, L)=1:1~1:8, after heating to 80~90℃, add 5%~20% HClO solution dropwise to control the dropping rate 8~10L / h, heating reaction for 4~5h. After 2 times of dissolution sampling and analysis, the dissolution rate of platinum was 99.41%, the dissolution rate of palladium was 99.30%, the dissolution rate of rhodium was 99.08%, and the total dissolution rate of platinum group metals was 99.30%.

Embodiment 3

[0023] Example 3 The contents of platinum group metals in the enrichment of an automobile exhausted catalyst are respectively (g), Pt2585.30, Pd7651.10, Rh1227.10, ∑PGMs11463.50. Add 12mol / L hydrochloric acid to the enriched product according to the solid-liquid ratio (S, L)=1:1~1:10, and after heating to 90~100℃, add 10%~20% HClO dropwise 4 solution, control the dropping rate of 10-20L / h, and heat the reaction for 4-6h. After three times of dissolution, sampling and analysis, the dissolution rate of platinum was 99.50%, the dissolution rate of palladium was 99.86%, the dissolution rate of rhodium was 99.46%, and the total dissolution rate of platinum group metals was 99.74%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com