Device for producing polyamide 6POY/FDY composite fiber according to high-speed spinning and confounding one-step method

A high-speed spinning and composite fiber technology, applied in the field of spinning equipment, can solve the problems of high production cost, shortened process flow, and long technical process flow, and achieve the effects of short production process, stable quality, and good melt uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

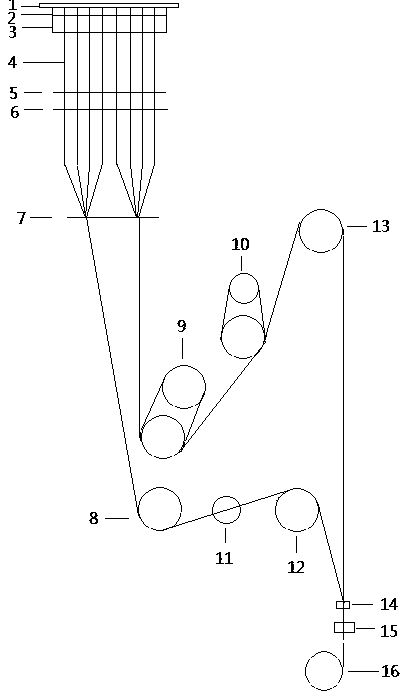

[0017] The equipment provided in this example for producing polyamide 6POY / FDY composite fibers in one-step method of high-speed spinning and interlacing, the spinning box is mainly composed of metering pump, spinning assembly, spinneret and box shell, its main function The polyamide melt is extruded through the metering pump, spinning assembly and spinneret in the spinning box to form a thin stream of melt, which plays the role of uniform temperature and heat preservation. see figure 1 , which is a structural schematic diagram of the equipment for producing polyamide 6POY / FDY composite fibers by the one-step method of interlacing. The main devices include spinneret 1, slow cooling device 2, ring air cooling device 3, oil injection device 5, and the first stretching roller Group 9, second drawing heat roll group 10, first godet 8, tension regulator 11, second godet 12, third godet 13, doubling device 14, interlacing nozzle 15 and winding device 16.

[0018] Slow cooling devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com