Different-shrinkage polyamide 6POY/FDY (Polyester Pre-Oriented Yarn/Fully Drawn Yarn) composite fiber and preparation method thereof

A technology of different shrinkage polyamide and composite fiber, which is applied in fiber treatment, conjugated synthetic polymer artificial filament, melt spinning, etc., to achieve the effect of stable quality, short process and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

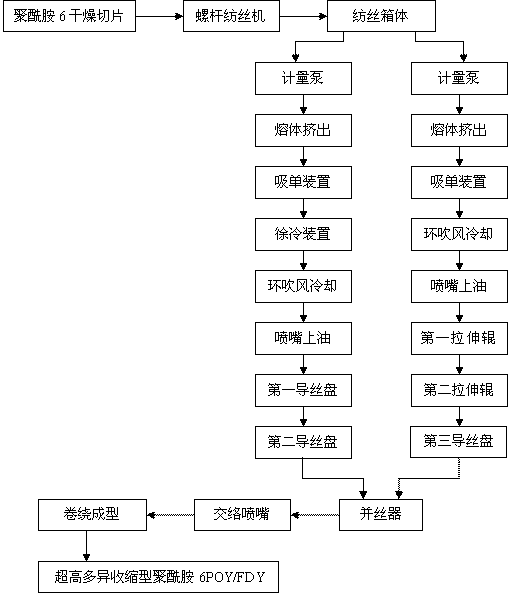

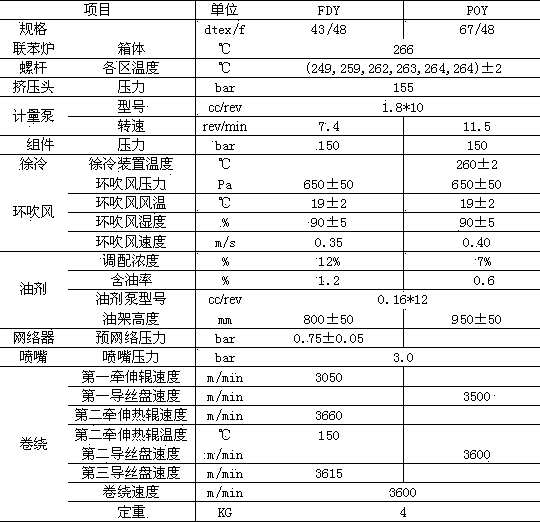

[0021] This example provides a 110dtex / 96f (including: 43dtex / 48f fully drawn yarn, 67dtex / 48f pre-oriented yarn) one-step ultra-high polyisotropic shrinkage polyamide 6POY / FDY composite fiber and its preparation method, and its process flow See attached figure 1 . The production process is as follows:

[0022] The polyamide 6 dry chips that meet the requirements of the spinning process index are input into the screw, heated, melted and filtered, and then enter the spinning box. The spinning melt is extruded from the micropores of two metering pumps, spinning components and two spinnerets. One bundle of filaments is cooled and solidified by surrounding air blowing, oiled on the nozzle, pre-networked, stretched and heat-set between the first drafting roll and the second drafting hot roll, and then fed into the third godet to obtain a poly Amide 6FDY; another bundle of filaments is solidified and formed by slow cooling and ring blowing cooling, nozzle oiling, guide wire windin...

Embodiment 2

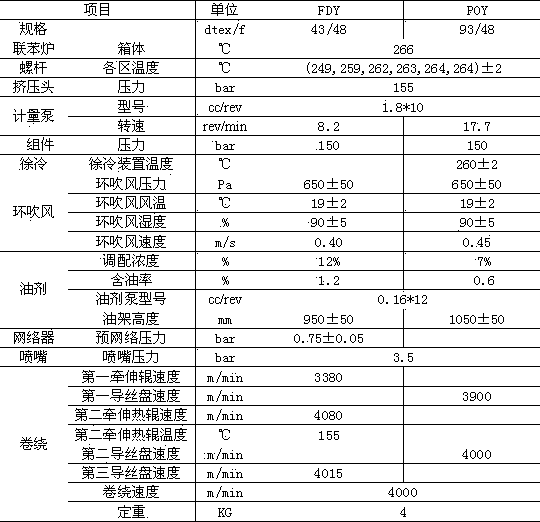

[0028] This example provides a 136dtex / 96f (including: 43dtex / 48f fully drawn yarn, 93dtex / 48f pre-oriented yarn) method for preparing ultra-high polyisotropic shrinkable polyamide 6POY / FDY composite fibers in one step. For the process flow, see attached figure 1 . The production process is as follows:

[0029]The polyamide 6 dry chips that meet the requirements of the spinning process index are input into the screw, heated, melted and filtered, and then enter the spinning box. The spinning melt is extruded from the micropores of two metering pumps, spinning components and two spinnerets. One bundle of filaments is cooled and solidified by circular air blowing, oiled on the nozzle, pre-networked, stretched and heat-set between the first drafting roll and the second drafting hot roll, and then input into the third godet to obtain a poly Amide 6FDY; another bundle of filaments is cooled and solidified by slow cooling and circular air blowing, the nozzle is oiled, and the guide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com