A system and method for coal-to-natural gas co-production of methanol

A technology for coal-to-natural gas and natural gas, applied in the field of coal-to-natural gas co-production of methanol, can solve problems such as greenhouse effect and carbon element loss, and achieve the effects of improving utilization rate, reducing emissions, and diversifying product structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

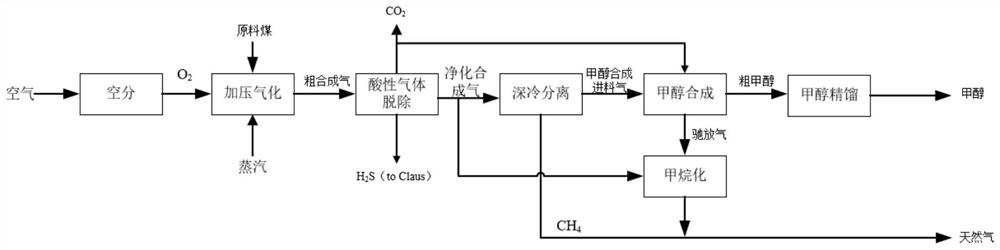

[0055] The air flow rate is 400000Nm 3 / h into the air separation unit, separated to get 85000Nm 3 Oxygen product of / h (O 2 The content is 99.5mol%) and 310000Nm 3 / h nitrogen product (N 2 content of 99.0mol%), the raw material lignite flow rate is 260t / h, together with oxygen and medium-pressure steam, enter the coal gasification unit (gasifier temperature is 1050°C, pressure is 4.0MPaA), the crude synthesis produced by the coal gasification unit The gas volume is 27,760 kmol / h. After the crude synthesis gas enters the acid gas removal unit to remove carbon dioxide and sulfide, the purified synthesis gas (CO 2 The content is 0.05ppm, H 2 The S content is 0.05ppm) and the amount is 18230kmol / h, the hydrogen-carbon ratio of the purified syngas is 2.7,

[0056] The split ratio of the purified syngas at the outlet of the acid gas removal unit is 0.25, a part of the purified syngas (20% of the purified syngas) enters the methanation unit, and the other part (80% of the purif...

Embodiment 2

[0058] The air flow rate is 401500Nm 3 / h into the air separation unit, separated to get 85000Nm 3 Oxygen product of / h (O 2 The content is 99.5mol%) and 316000Nm 3 / h nitrogen product (N 2 content of 99.0mol%), the raw material lignite flow rate is 260t / h, together with oxygen and medium-pressure steam, enter the coal gasification unit (gasifier temperature is 1050°C, pressure is 4.0MPaA), the crude synthesis produced by the coal gasification unit The gas volume is 27,760 kmol / h. After the crude synthesis gas enters the acid gas removal unit to remove carbon dioxide and sulfide, the purified synthesis gas (CO 2 The content is 0.05ppm, H 2 The S content is 0.05ppm) and the amount is 18230kmol / h, the hydrogen-carbon ratio of the purified syngas is 2.7,

[0059] The split ratio of the purified syngas at the outlet of the acid gas removal unit is 0.25, a part of the purified syngas (20% of the purified syngas) enters the methanation unit, and the other part (80% of the purif...

Embodiment 3

[0061] The air flow rate is 400000Nm 3 / h into the air separation unit, separated to get 85000Nm 3 Oxygen product of / h (O 2 The content is 99.5mol%) and 310000Nm 3 / h nitrogen product (N 2 content of 99.0mol%), the raw material lignite flow rate is 260t / h, together with oxygen and medium-pressure steam, enter the coal gasification unit (gasifier temperature is 1050°C, pressure is 4.0MPaA), the crude synthesis produced by the coal gasification unit The gas volume is 27,760 kmol / h. After the crude synthesis gas enters the acid gas removal unit to remove carbon dioxide and sulfide, the purified synthesis gas (CO 2 The content is 0.05ppm, H 2 The S content is 0.05ppm) and the amount is 18230kmol / h, the hydrogen-carbon ratio of the purified syngas is 2.7,

[0062] The split ratio of the purified syngas at the outlet of the acid gas removal unit is 0.43, a part of the purified syngas (30% of the purified syngas) enters the methanation unit, and the other part (70% of the purif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com