Method for recycling waste emulsion explosive in rock powder emulsion explosive

A technology for powder emulsion explosives and emulsion explosives, which is used in explosives, explosives processing equipment, non-explosive/non-thermal components, etc., can solve the problems of high requirements on the surrounding environment, difficult separation, and difficult implementation, so as to avoid waste of resources and Environmental pollution, simple production technology, stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

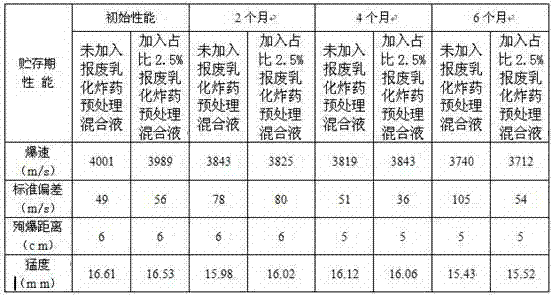

Examples

Embodiment 1

[0041] (1) Preparation of aqueous phase of rock powdery emulsion explosive

[0042] Weigh 86.29kg of ammonium nitrate and 0.19kg of sodium nitrate, dissolve them in 6.51kg of water, then add 0.019kg of sodium methylene bis-naphthalene sulfonate dispersant to the solution, stir to dissolve and heat to control the temperature at 118-125°C for later use.

[0043] (2) Preparation of oil phase for rock powdery emulsion explosives

[0044] Weigh 2.5kg of solid composite oil phase (including puffing agent), melt it, then add it to 2.5kg of liquid composite oil phase, mix evenly, heat and control the temperature at 85-90°C for later use.

[0045] (3) Pretreatment of scrapped emulsion explosives

[0046] a) Weigh 0.34kg of special composite wax for explosives and put it into a melting tank, add 0.06kg of polyisobutylene-infused biological polymer surfactant after melting, heat and stir to raise the temperature and control it between 95°C and 120°C;

[0047] b) Weigh 1.5kg of scrap em...

Embodiment 2

[0054] (1) Preparation of aqueous phase of rock powdery emulsion explosive

[0055] Weigh 88.63kg of ammonium nitrate and 0.094kg of sodium nitrate, dissolve them in 5.26kg of water, then add 0.0094kg of sodium methylene bis-naphthalene sulfonate dispersant to the solution, stir to dissolve and heat to control the temperature at 118-125°C for later use.

[0056] (2) Preparation of oil phase for rock powdery emulsion explosives

[0057] Weigh 1.8kg of solid composite oil phase (including puffing agent), melt it, then add it to 1.2kg of liquid composite oil phase, mix evenly, heat and control the temperature at 85-90°C for later use.

[0058] (3) Pretreatment of scrapped emulsion explosives

[0059] a) Weigh 0.66kg of special composite wax for explosives and put it into the melting tank, add 0.12kg of polyisobutylene-infused biological polymer surfactant after melting, heat and stir to raise the temperature and control it between 95°C and 120°C;

[0060] b) Weigh 2.1kg of scra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com