Profiled steel sheet composite board as well as roofing board, floor board or wall panel with composite boards

A technology of profiled steel plate and composite plate, which is applied in the direction of roof, roof and roof covering layer using flat/curved plate, can solve the problems of complex production process, limitation and use, etc., and achieves easy popularization and application, strong applicability, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

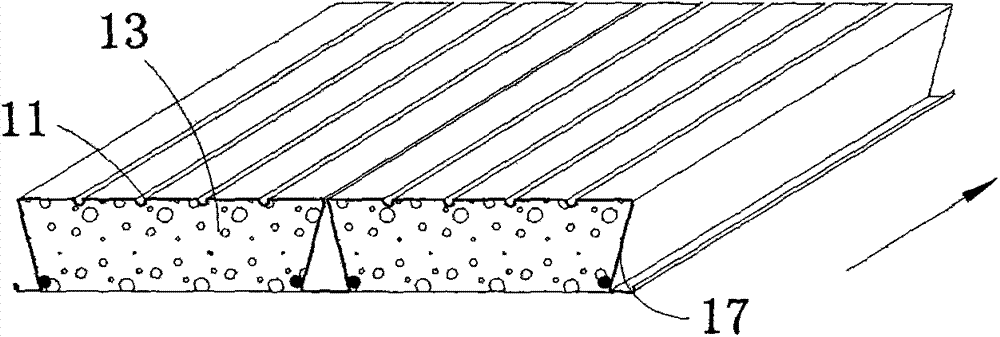

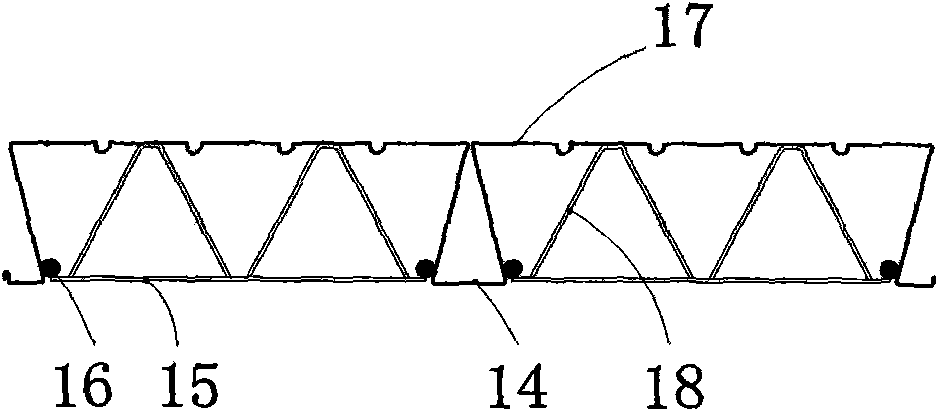

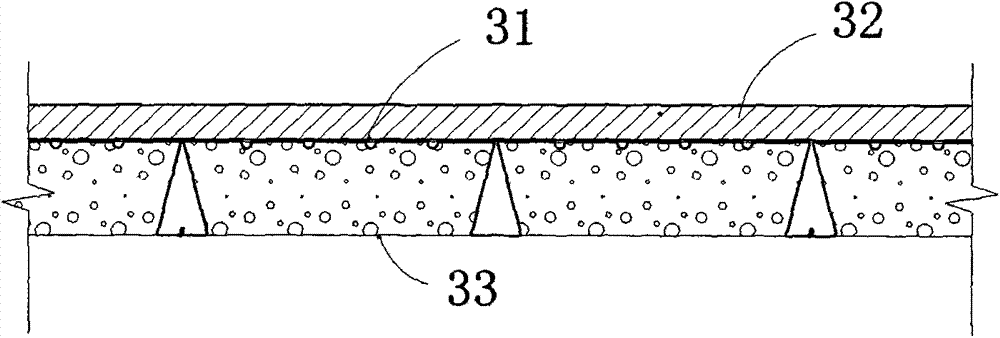

[0026] see figure 1 and 2 As shown, it is a structural schematic diagram of the novel profiled steel plate composite plate of the present invention and its cross-section. The composite plate of the present invention includes a profiled steel plate 17 and a foam concrete 13, wherein the profiled steel plate 17 is a rib plate, which is used as a composite plate The main body of the force; the foam concrete 13 is filled in the lower cavity of the profiled steel plate 17 to meet the requirements of functions such as heat preservation, sound insulation, fire prevention, and sound absorption.

[0027] In the present invention, the foamed concrete 13 can be composited with other lightweight materials.

[0028] In the present invention, the profiled steel plate 17 is pressed and formed by special equipment, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com