Forming method of resin matrix composite reinforcing ribs

A technology of composite materials and molding methods, which is applied in the field of structural molding of carbon fiber reinforced resin-based composite materials, can solve problems such as difficulty in meeting rapid prototyping requirements, and achieve the effect of simple and easy molding methods, simple and easy molding molds, and smooth and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

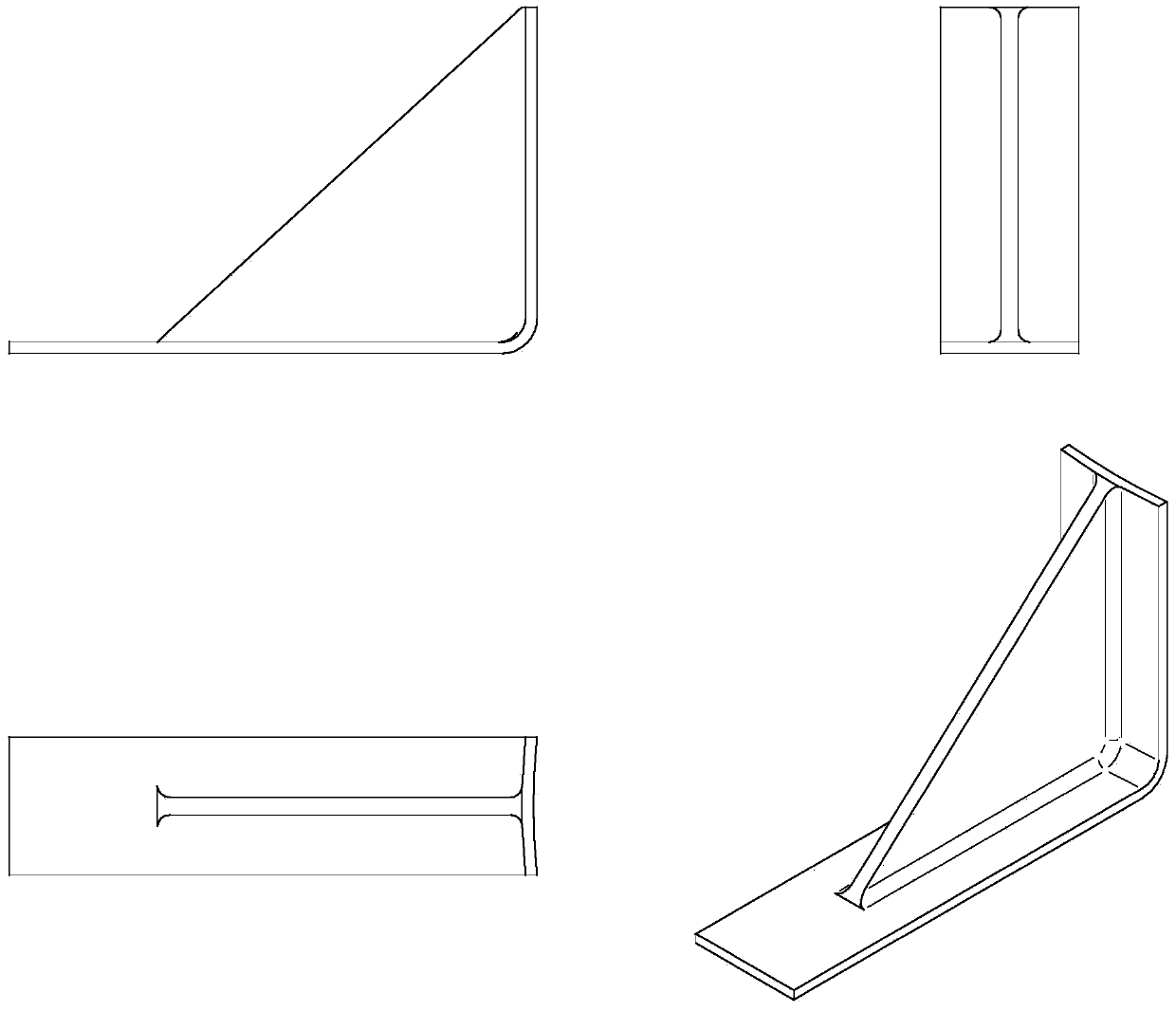

[0044] A method for rapid prototyping of reinforced ribs in resin-based composites, such as figure 1 As shown, the cross-section of the main body of the reinforcement rib to be formed is L-shaped; the vertical rib in the middle is used to further improve the stiffness of the reinforcement rib, and the reinforcement fiber between the main body and the main body is required to be as continuous as possible to fully exert the mechanical effect of the vertical rib; the product The wall thickness is 3mm, and the carbon fiber reinforced epoxy resin pre-impregnated non-weft cloth is used to lay up symmetrically to form quasi-isotropy, and the outer surface of the main body of the product is a circular arc surface.

[0045] The steps of the molding method are:

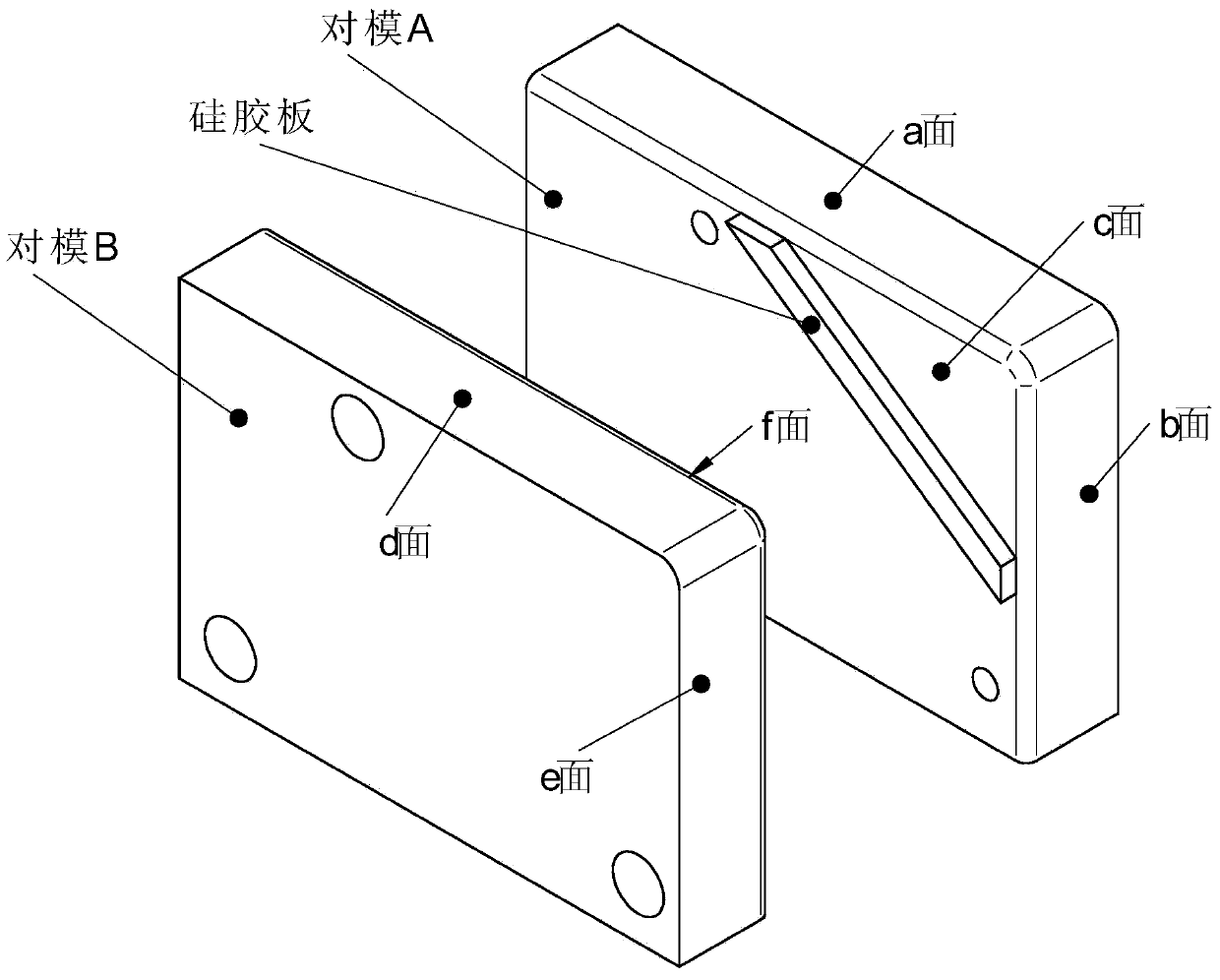

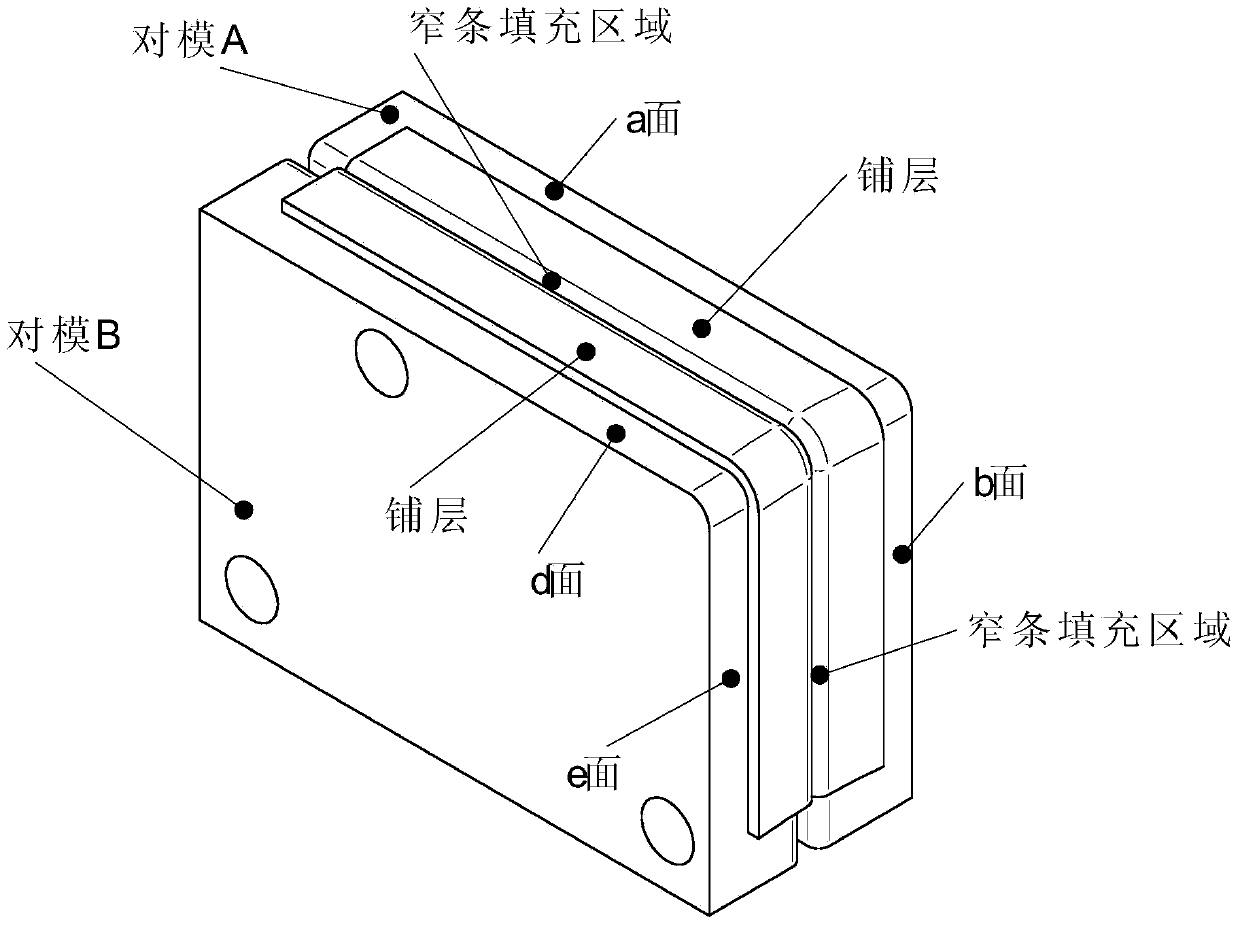

[0046] 1) Prepare the forming mold: such as figure 2 , the forming mold includes counter-die A, counter-die B and positioning pins; the sides of counter-die A and counter-die B are used to form the reinforcement rib main body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com