Process for making agar biscuits

A production process and technology of seaweed, applied in the processing of dough, baking, baked food, etc., can solve problems such as difficult digestion and absorption, and achieve the effects of easy digestion and absorption, outstanding flavor of seaweed, and delicate taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

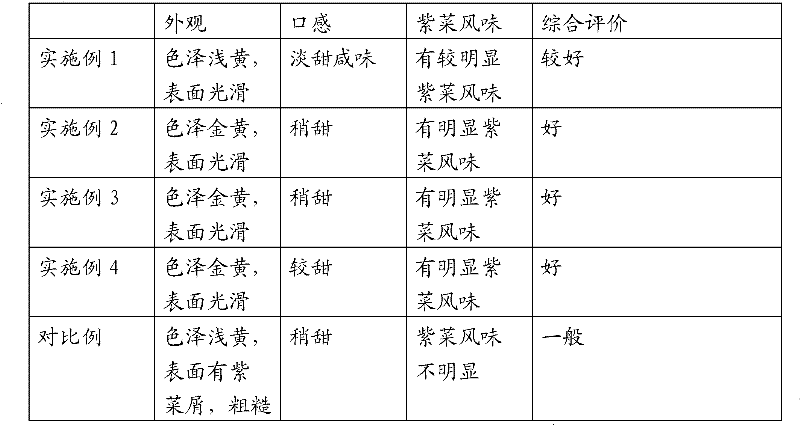

Examples

Embodiment 1

[0025] A kind of manufacture technology of laver biscuit, comprises the steps:

[0026] 1) Minor processing of seaweed

[0027] Remove the dirt, sand, algae and other impurities in the seaweed raw materials, wash them with clean water, dry them in the sun, and turn them frequently during the sun-drying process until the water content is 7%; coarsely crush the dried seaweed until the particle size is 30 mesh, Then use ultrafine pulverizer (jet pulverizer, model is QYF-260) that dry laver granule is further pulverized into particle size and is 150 mesh microparticles;

[0028] 2) Configure raw and auxiliary materials

[0029] The components of the raw and auxiliary materials are as follows in parts by mass: 100 parts of low-gluten flour, 6 parts of seaweed powder, 20 parts of white sugar, 0.5 parts of table salt, 10 parts of margarine, 5 parts of milk powder, 8 parts of eggs, 0.5 parts of baking soda, 0.2 part of potassium hydrogen tartrate, 0.3 part of sucrose fatty acid este...

Embodiment 2

[0035] A kind of manufacture technology of laver biscuit, comprises the steps:

[0036] 1) Minor processing of seaweed

[0037] Remove the dirt, sand, algae and other impurities in the seaweed raw materials, wash them with clean water, dry them in the sun, and turn them frequently during the drying process until the water content is 9%; coarsely crush the dried seaweed until the particle size is 20 mesh, Then use ultrafine pulverizer (jet pulverizer, model is QYF-260) that dry laver granule is further pulverized into particle size and is 120 mesh microparticles;

[0038] 2) Configure raw and auxiliary materials

[0039] The components of the raw and auxiliary materials are as follows in parts by mass: 100 parts of low-gluten flour, 8 parts of seaweed powder, 25 parts of white sugar, 0.6 parts of table salt, 12 parts of margarine, 6 parts of milk powder, 9 parts of eggs, 0.6 parts of baking soda, 0.3 part of potassium hydrogen tartrate, 0.5 part of sucrose fatty acid ester; ...

Embodiment 3

[0045] A kind of manufacture technology of laver biscuit, comprises the steps:

[0046] 1) Minor processing of seaweed

[0047] Remove the dirt, sand, algae and other impurities in the seaweed raw materials, wash them with clean water, dry them in the sun, and turn them frequently during the sun-drying process until the water content reaches 10%; coarsely crush the dried seaweed until the particle size is 20 meshes, Then use ultrafine pulverizer (jet pulverizer, model is QYF-260) that dry laver granule is further pulverized into particle size and is 120 mesh microparticles;

[0048] 2) Configure raw and auxiliary materials

[0049] The components of the raw and auxiliary materials are as follows in parts by mass: 110 parts of low-gluten flour, 9 parts of seaweed powder, 25 parts of white sugar, 0.7 parts of table salt, 14 parts of margarine, 7 parts of milk powder, 10 parts of eggs, 0.8 parts of baking soda, 0.3 part of potassium hydrogen tartrate, 0.6 part of sucrose fatty ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com