Manufacturing technology of ceramic water tap housing

A faucet shell and manufacturing process technology, applied in the field of manufacturing process of ceramic faucet shells, can solve the problems of low strength of faucet shell materials, affecting service life, domestic water pollution, etc., achieving light weight, light weight, and avoiding pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

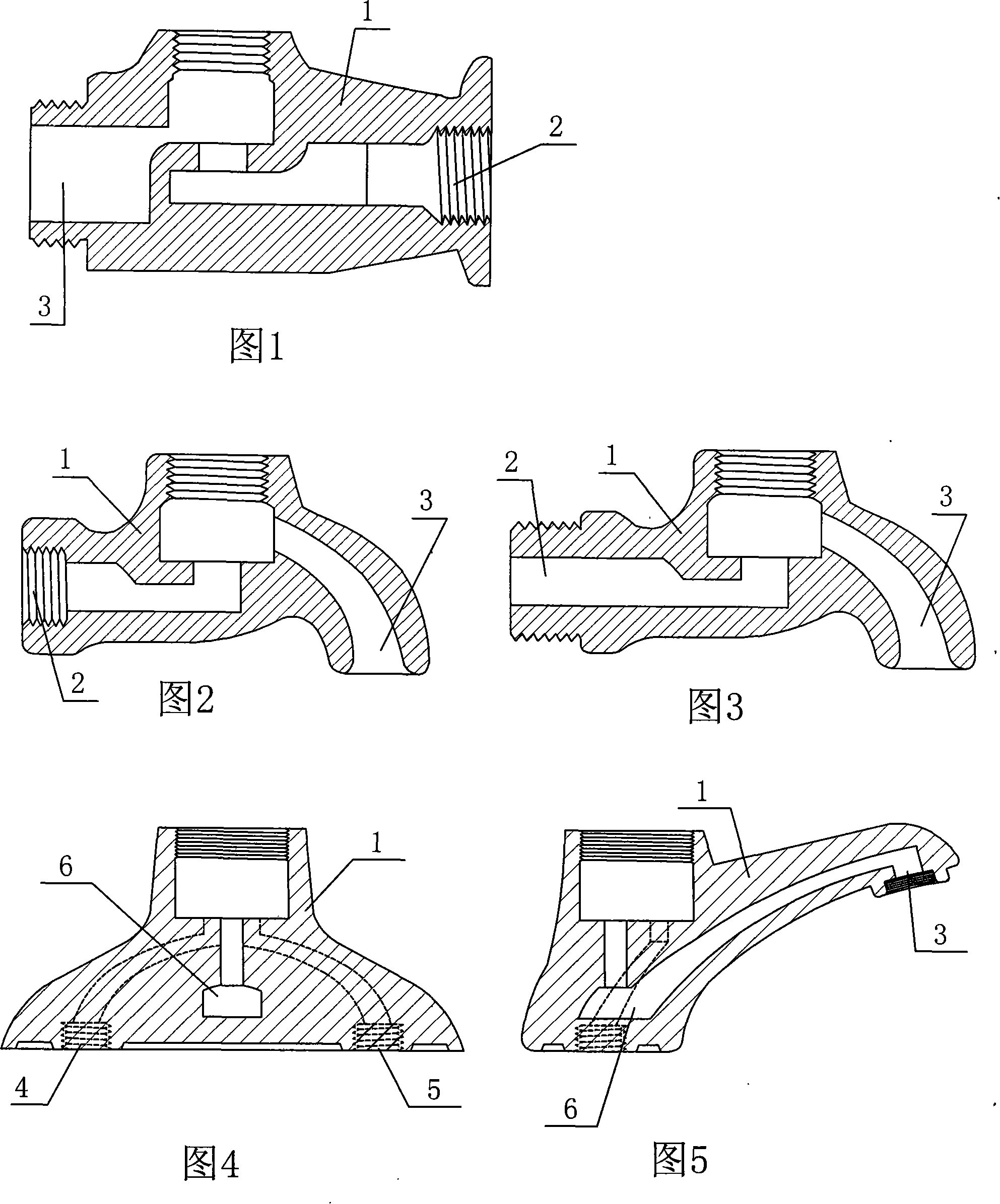

Image

Examples

Embodiment 1

[0034] Prepare the faucet in the following order of steps:

[0035] (1) Select 10 parts of raw talc, 70 parts of calcined cooked talc, 15 parts of clay, and 5 parts of BaCO 3 Additives are mixed (above all are weight and number ratio);

[0036] (2) Calcining the above-mentioned mixed raw materials to 1350° C., then grinding with a ball mill for 30 hours, and sieving to obtain a 270-mesh ultrafine powder;

[0037] (3) Take the paraffin wax with a weight of 18% of the powder weight and heat it to melt the paraffin wax into a liquid, then gradually add the powder to the paraffin wax solution, stir while heating, and mix the two evenly to make a slurry. Control the temperature around 60°C;

[0038] (4) Make the uniformly mixed slurry into a faucet shell blank of a specified shape through a hot die-casting process;

[0039] (5) Calcining and dewaxing the faucet shell blank, then polishing the surface, and finally glazing to make a semi-finished product;

[0040] (6) Finally, th...

Embodiment 2

[0042] Prepare in the following order of steps:

[0043] (1) Select 15 parts of raw talc, 65 parts of calcined cooked talc, 12 parts of clay, and 8 parts of BaCO 3 Additives are mixed (above all are weight and number ratio);

[0044] (2) The above-mentioned mixed raw materials were first calcined to 1330° C., then ground for 32 hours with a ball mill, and sieved to obtain a 280-mesh ultrafine powder;

[0045] (3) Take the paraffin wax with a weight of 19% of the powder weight and heat it to melt the paraffin wax into a liquid, then gradually add the powder to the paraffin wax solution, stir while heating, and mix the two evenly to make a slurry. Control the temperature around 58°C;

[0046] (4) Make the uniformly mixed slurry into a faucet shell blank of a specified shape through a hot die-casting process;

[0047] (5) Calcining and dewaxing the faucet shell blank, then polishing the surface, and finally glazing to make a semi-finished product;

[0048] (6) Finally, the se...

Embodiment 3

[0050] Prepare in the following order of steps:

[0051] (1) Select 18 parts of raw talc, 62 parts of calcined cooked talc, 10 parts of clay, and 10 parts of BaCO 3 Additives are mixed (above all are weight and number ratio);

[0052] (2) The above-mentioned mixed raw materials were first calcined to 1390°C, then ground for 36 hours with a ball mill, and sieved to obtain a 300-mesh ultrafine powder;

[0053] (3) Take paraffin wax with a weight of 20% of the powder weight and heat it to melt the paraffin wax into a liquid, then gradually add the powder to the paraffin wax solution, stir while heating, and mix the two evenly to make a slurry. Control the temperature at 80°C;

[0054] (4) Make the uniformly mixed slurry into a faucet shell blank of a specified shape through a hot die-casting process;

[0055] (5) Calcining and dewaxing the faucet shell blank, then polishing the surface, and finally glazing to make a semi-finished product;

[0056] (6) Finally, the semi-finish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com