Vacuum perfusion forming method of p-aramid fiber composite material workpiece

A technology of vacuum infusion and composite materials, which is applied in the field of vacuum infusion molding of para-aramid fiber composite materials, can solve the problems that para-aramid fiber composite materials have not been used, and is rare, and achieves good performance and control of content. The effect of high glue quantity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

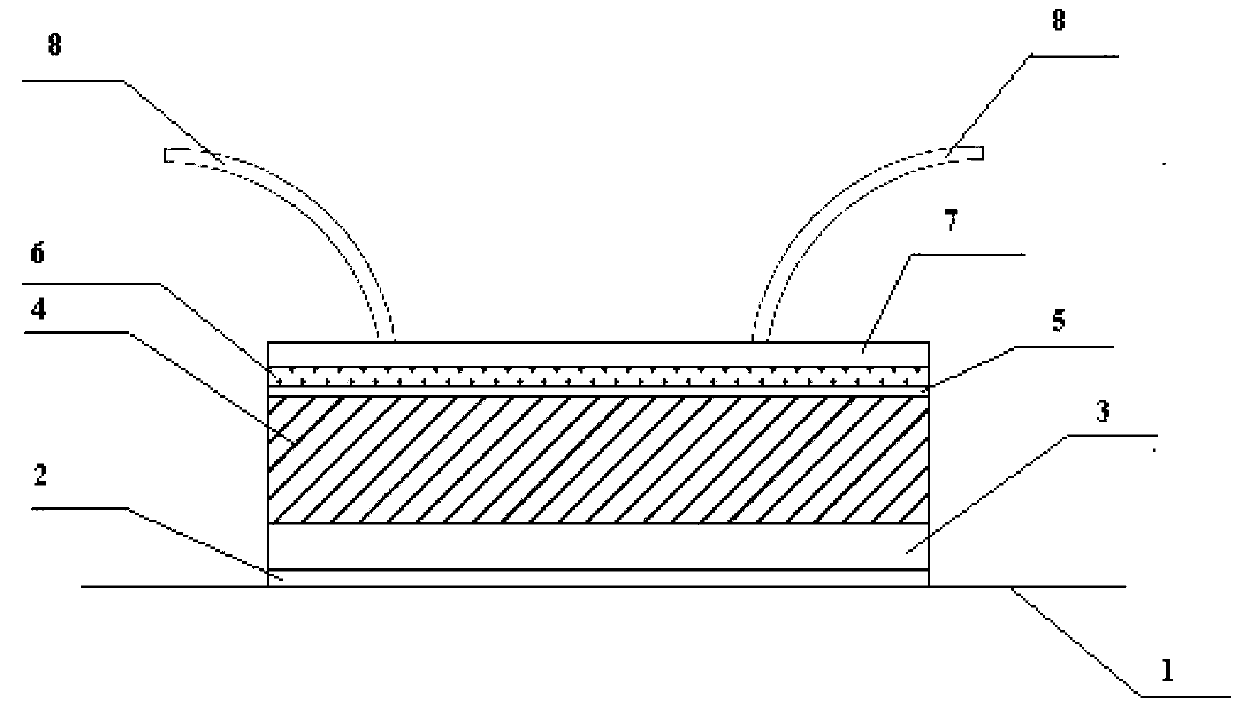

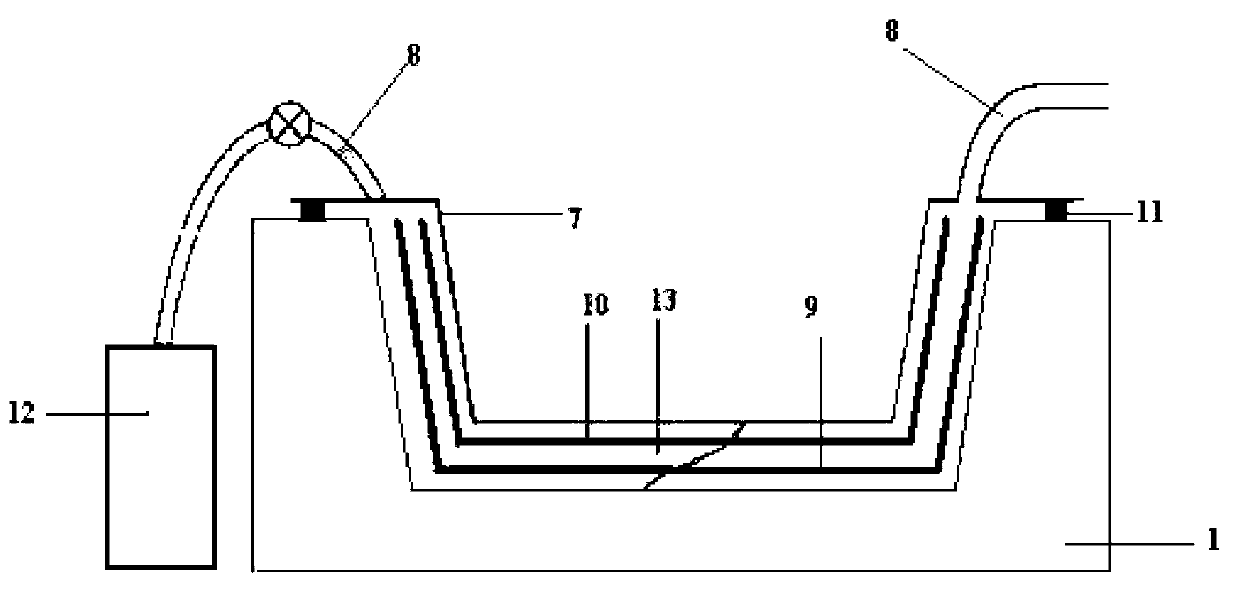

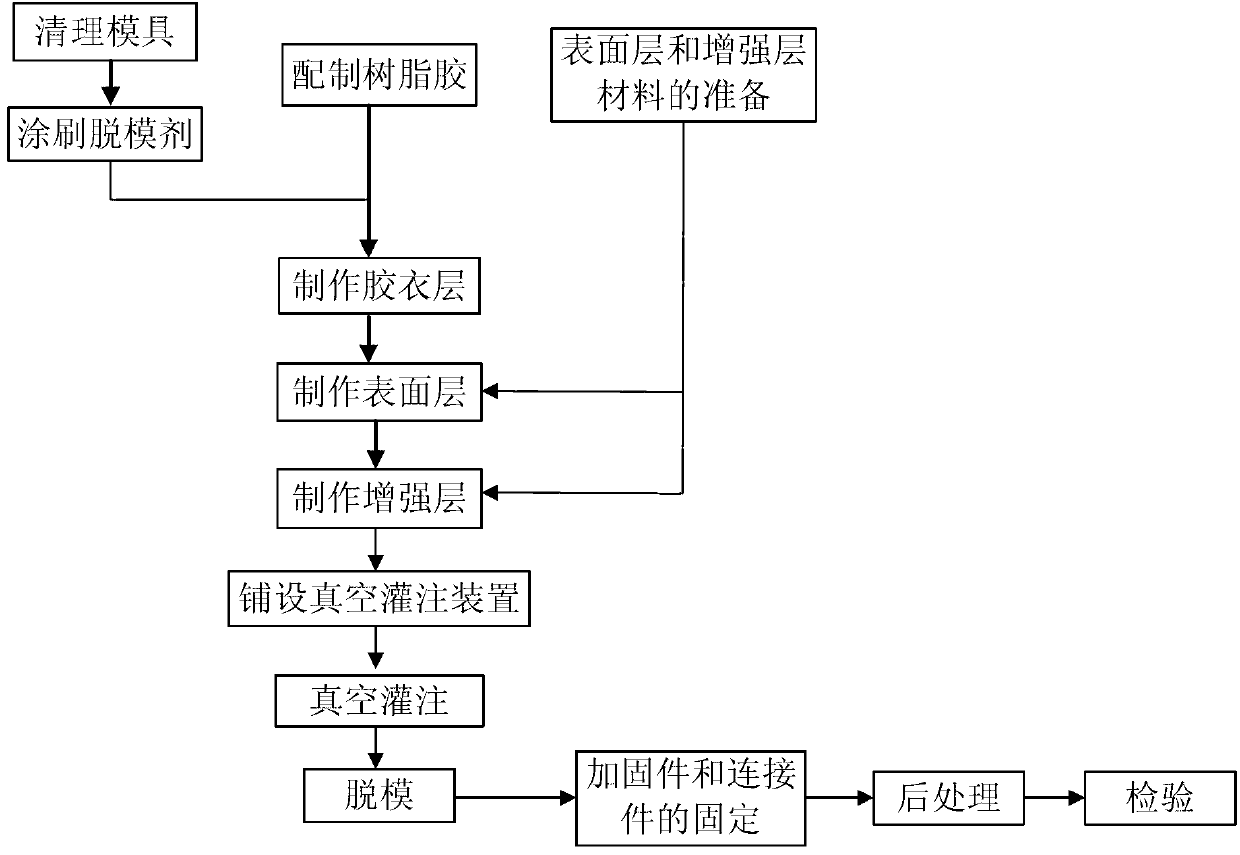

[0125] A vacuum infusion molding method for para-aramid composite parts, figure 1 with figure 2 It is a schematic diagram of the layered structure of the para-aramid composite material during the vacuum infusion process of the present invention, such as image 3 As shown, the method includes the following steps:

[0126] 1. Clean the mold 1

[0127] The combined mold 1 made of stainless steel material includes opposite female molds and male molds, and the prepared para-aramid composite material is a rectangular plate-shaped part. Use a flat spatula to carefully remove the residual glue left over from the last demolding on the mold 1 without damaging the surface; rinse the mold release agent with water and wipe it dry for later use.

[0128] 2. Brush release agent

[0129] Heat 45 parts of water to 60~70℃, add 5 parts of polyvinyl alcohol (low molecular powder, average molecular weight of 16000~20000), keep warm and stir until it is completely dissolved, then cool to room temperature,...

Embodiment 2

[0171] A vacuum infusion molding method for para-aramid composite parts, figure 1 with figure 2 It is a schematic diagram of the layered structure of the para-aramid composite material during the vacuum infusion process of the present invention, such as image 3 As shown, the method includes the following steps:

[0172] 1. Clean the mold 1

[0173] A combined mold 1 made of stainless steel is used, including opposite female molds and male molds, and the prepared para-aramid composite parts are rectangular parts. Stick the residual glue left over from the last demolding to the mold, use a flat spatula to carefully remove it, and not damage the surface; wash the mold release agent with water, and wipe it dry for later use.

[0174] 2. Brush release agent

[0175] Heat 45 parts of water to 60~70℃, add 5 parts of polyvinyl alcohol (low molecular powder, average molecular weight of 16000~20000), keep warm and stir until it is completely dissolved, then cool to room temperature, then stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com