Easy-to-disperse carbon nanotube master batch as well as preparation method and application thereof

A carbon nanotube and easy-dispersion technology, applied in the field of carbon nanotubes, can solve the problems of destroying the mechanical properties of polyolefins, low carbon nanotube content concentration, harsh processing conditions, etc. Green environmental protection, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

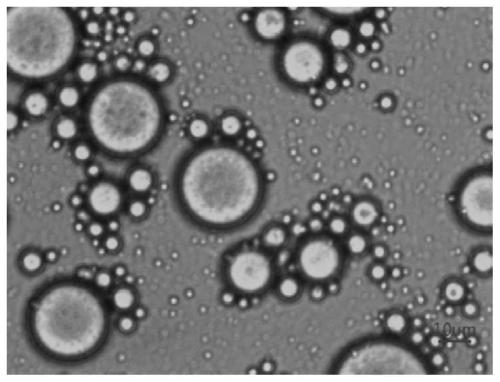

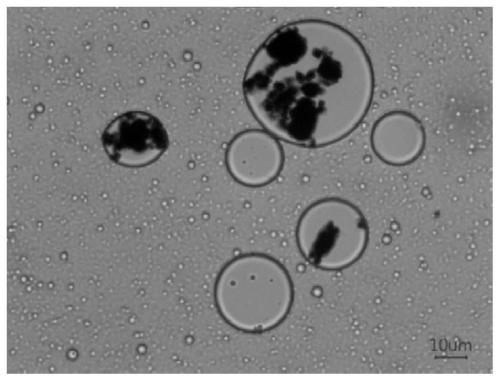

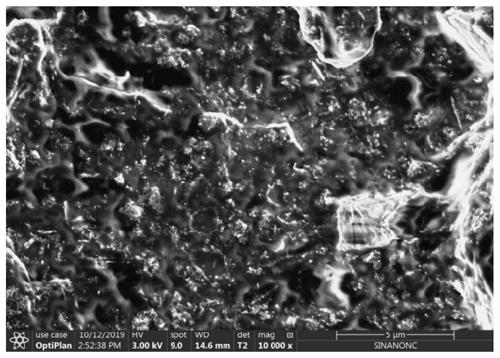

[0055] Mix 720g of 3# white oil with 80g of polyether silicone emulsifier, stir gently, then transfer to the emulsification pump for strong emulsification and mixing for 3 minutes. After mixing, it was poured into a 50L container filled with 8000g of deionized water to form a coarse dispersion emulsion. Start the high-speed disperser, maintain the rotating speed at 1500r / min, utilize the high-speed stirring paddle to disperse the emulsion at high speed for 10min, obtain the micro-nano emulsion (such as figure 1 shown). After reaching the predetermined stirring time, stop stirring and add 800g to the emulsion GT300, 10g antioxidant 1010, continue stirring at high speed to disperse for 20 minutes, then stop stirring again (such as figure 2 shown). Add 6400g polyethylene powder into the container and stir at a low speed of 300r / min. After stirring at a low speed for 20 minutes, transfer the material in the container to an oven at 110°C and bake for 8 hours. After the fully...

Embodiment 2

[0057] Mix 720g of 32# white oil with 720g of emulsifier triton, stir slightly, then transfer to emulsification pump for strong emulsification and mixing for 15 minutes. After mixing, it was poured into a 50L container filled with 8000g of deionized water to form a coarse dispersion emulsion. Start the high-speed disperser, maintain the rotating speed at 3000r / min, and use the high-speed stirring paddle to disperse the coarsely dispersed emulsion at high speed for 15 minutes to obtain a micro-nano emulsion. After reaching the predetermined stirring time, stop stirring, add 400g multi-walled carbon nanotubes in the emulsion NC7000, 5g antioxidant 168, continue stirring at high speed to disperse for 15 minutes, then stop stirring again. Add 160g of polyethylene powder into the container and stir at a low speed of 150r / min. After stirring at a low speed for 15 minutes, transfer the material in the container to an oven at 130°C and bake for 10 hours. After the fully dried mate...

Embodiment 3

[0059] Mix 360g of 150# white oil with 40g of polyether silicone emulsifier, stir gently, transfer to emulsification pump for strong emulsification and mixing for 30min. After mixing, it was poured into a 50L container filled with 4000g of deionized water to form a coarsely dispersed emulsion. Start the high-speed disperser, maintain the rotating speed at 500r / min, and use the high-speed stirring paddle to disperse the coarsely dispersed emulsion at high speed for 30 minutes to obtain a micro-nano emulsion. After reaching the predetermined stirring time, stop stirring and add 800g to the emulsion GT300, 4g of antioxidant 1010 and 4g of antioxidant 168 were dispersed under high-speed stirring for 30 minutes, and then the stirring was stopped again. Add 400g of polyethylene powder into the container and stir at a low speed of 300r / min. After stirring at a low speed for 30 minutes, transfer the material in the container to a 90°C oven and bake for 12 hours. After the fully dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com