PLA (polylactic acid) modified material for 3D (three-dimensional) printing and preparation method thereof

A modified material, 3D printing technology, applied in the field of 3D printing materials, can solve the problem of high product price, achieve the effect of smooth product surface, increased compatibility, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

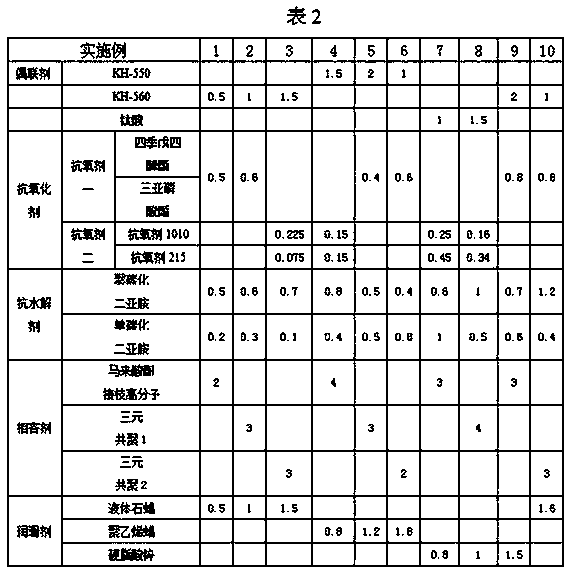

[0023] According to the amount of PLA modified material prepared, according to the component distribution ratio of Example 1 in Table 1, weigh the raw materials of each component of the preparation, wherein, other additives are used according to the ratio of Example 1 in Table 2, and then press The PLA modified material of this embodiment is prepared respectively in steps:

[0024] a. Dry raw materials: Dry the polylactic acid resin with a molecular weight of 50,000-60,000 and a melt flow index of not more than 10-11g / 10min (190°C, 2.16kgf) at 100°C for 4.5h, and set aside;

[0025]b. Treatment of inorganic fillers and coupling agents: Make the coupling agent into an aqueous solution, then add acetic acid to adjust the pH value to 4.5, add the solution to the inorganic filler with a particle size of 2500 mesh in the form of spray, and then use a high-speed mixer to mix evenly and place Half an hour, dry at 50°C for 1 hour, then raise the temperature to 80°C and dry for 1 hou...

Embodiment 2

[0029] According to the amount of the prepared PLA modified material, according to the component distribution ratio of Example 2 in Table 1, weigh the raw materials of each component of the preparation, wherein, other additives are used according to the ratio of Example 2 in Table 2, and then press The PLA modified material of this embodiment is prepared respectively in steps:

[0030] a. Dry raw materials: Dry the polylactic acid resin with a molecular weight of 70,000-80,000 and a melt flow index of 12-13g / 10min (190°C, 2.16kgf) at 80°C for 6h, and set aside;

[0031] b. Inorganic filler and coupling agent treatment: Make the coupling agent into an aqueous solution, then add acetic acid to adjust the pH value to 5, add the solution to the inorganic filler with a particle size of 3000 mesh in the form of spray, and then use a high-speed mixer to mix evenly, place Half an hour, dry at 60°C for 0.5 hours, then raise the temperature to 100°C and dry for 0.5 hours, set aside; ...

Embodiment 3

[0035] According to the amount of the prepared PLA modified material, according to the component distribution ratio of Example 3 in Table 1, weigh the raw materials of each component of the preparation, wherein, other additives are used according to the ratio of Example 3 in Table 2, and then press The PLA modified material of this embodiment is prepared respectively in steps:

[0036] a. Dry raw materials: dry polylactic acid resin with a molecular weight of 90,000-100,000 and a melt flow index of not more than 13-14g / 10min (190°C, 2.16kgf) at 90°C for 65 hours, and set aside;

[0037] b. Treatment of inorganic fillers and coupling agents: Make the coupling agent into an aqueous solution, then add acetic acid to adjust the pH value to 5, add the solution to the inorganic filler with a particle size of 3500 mesh in the form of spray, and then use a high-speed mixer to mix evenly and place Half an hour, dry at 55°C for 0.7 hours, then raise the temperature to 90°C and dry for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com