Elastomer modified asphalt waterproof coiled material as well as production technology and equipment thereof

A kind of asphalt waterproof membrane and production process technology, applied in the direction of asphalt layered products, layered products, building insulation materials, etc., can solve the problems of cumbersome process, complex composition, low performance, etc., and achieve simple process and simple composition , high performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

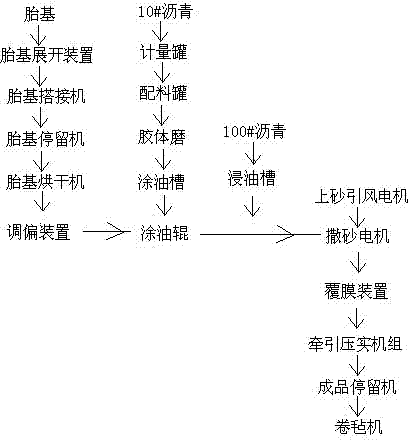

Method used

Image

Examples

Embodiment 1

[0020] An elastomer (SBS) modified asphalt waterproof membrane is prepared from the following raw materials in parts by weight:

[0021] 20 parts of 10# asphalt, 40 parts of 100# asphalt, 11 parts of engine oil, 12 parts of SBS (elastomer), 17 parts of talcum powder.

Embodiment 2

[0023] A kind of production technology of elastomer modified asphalt waterproof coiled material described in embodiment 1, comprises the following steps:

[0024] (1) Stirring of ingredients

[0025] 1. Prepare and weigh the raw materials used according to the above formula, and the raw materials should be classified and arranged neatly;

[0026] 2. After measuring 10# asphalt through the metering tank, put it into the batching tank, add engine oil when the temperature rises to 160±5°C, add elastomer SBS when the temperature rises to 180±5°C, and start the colloid mill while stirring 2. -3 times, when stirring for 80 minutes to 100 minutes, the temperature is controlled at 180-190°C. When the temperature rises to 200°C-210°C, add talcum powder and stir for half an hour. After checking that the mixing ingredients are sufficient, the temperature is controlled at this time Between 170-180 ℃, and take samples for semi-finished product testing;

[0027] In addition, after heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com