Preparation method of high-molecular nylon powder material used for 3D printing

A nylon powder and 3D printing technology, applied in the field of 3D printing materials, can solve the problems of low product precision and insufficient surface smoothness, and achieve the effect of uniform thickness distribution, easy rapid promotion, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

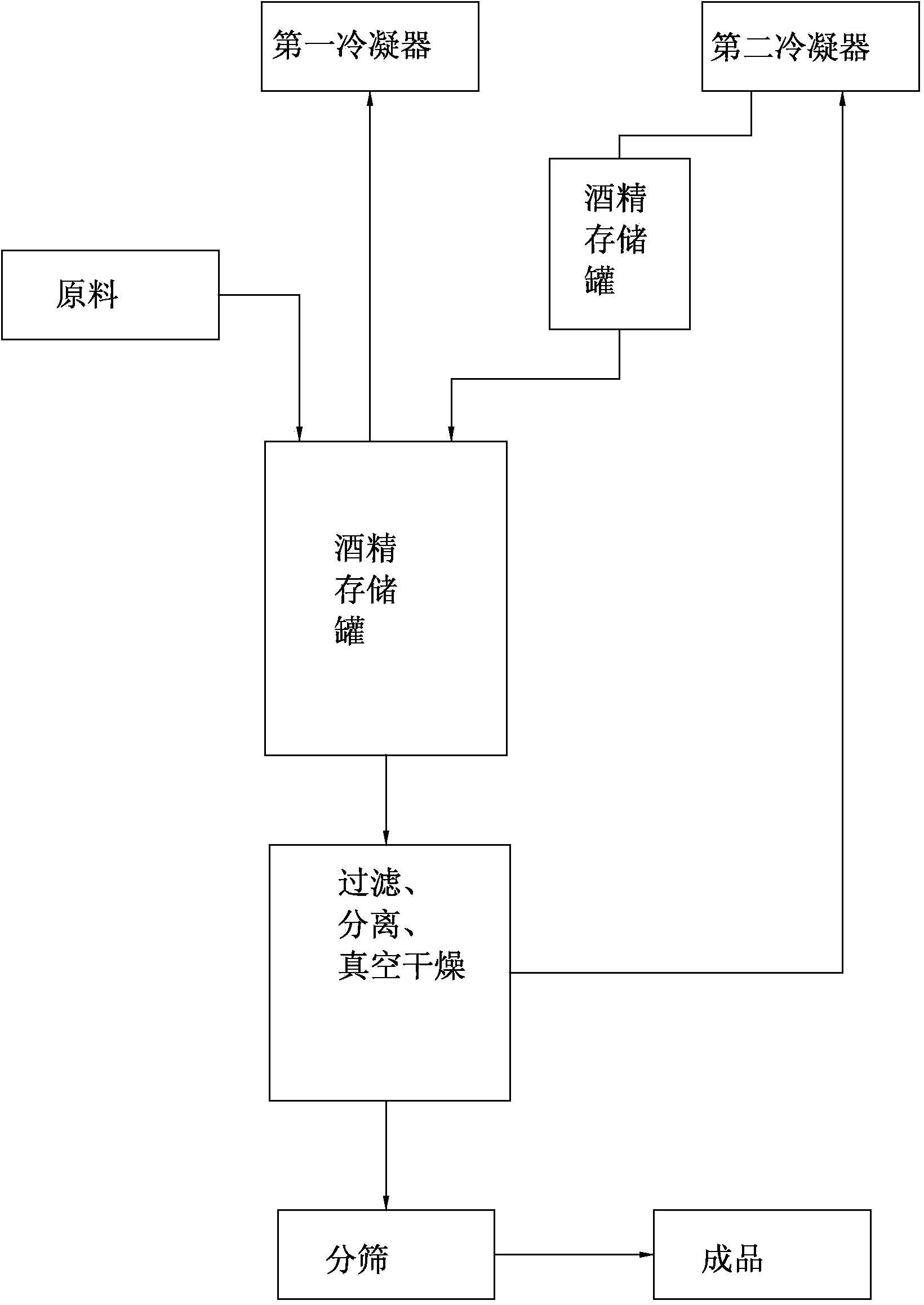

[0022] combine figure 1 As shown, when making the present invention, the first step needs to prepare corresponding raw materials and prepare a high-pressure reactor 1 . The autoclave 1 should have a built-in stirring device, and its volume is 3000 liters. The required raw materials are: nylon material, nucleating agent, antioxidant, alcohol. Among them, the nylon material is nylon 12, its chemical name is: polydodecamide, and its molecular formula is: [NH-(CH 2 ) 11 -CO] N . This nylon material has a low melting point, its appearance is white and translucent, and its relative density is low. Of course, nylon 11 can also be used as the nylon material of the present invention. Put the above-mentioned raw materials into the autoclave. Described alcohol is as the solvent of nylon material, and it adopts the alcohol solution that concentration is greater than 96%; Described nucleating agent is nano-scale silicon dioxide material; The weight specific gravity of alcohol, nylon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com