Hyperbranched ester compound and nylon fiber-added composite material and preparation method thereof

A technology of ester compounds and composite materials, which is applied in the field of hyperbranched ester compounds and nylon fiber-reinforced composite materials and their preparation, and can solve the problem of high roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

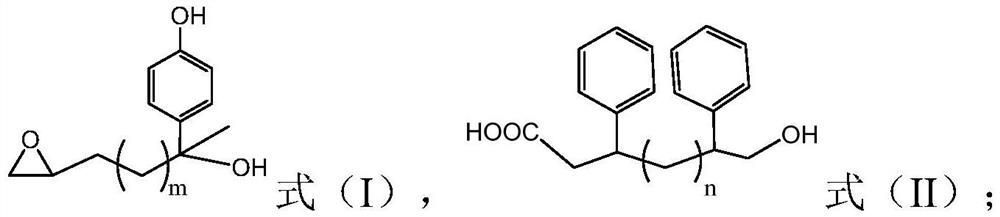

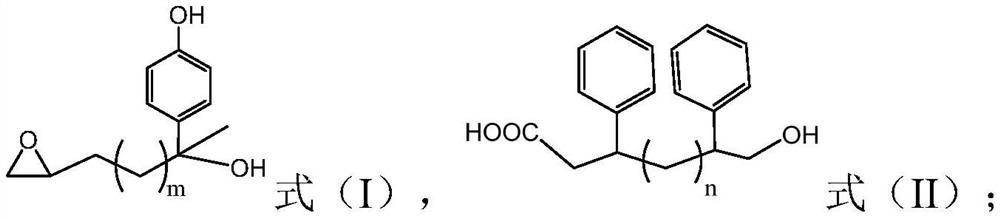

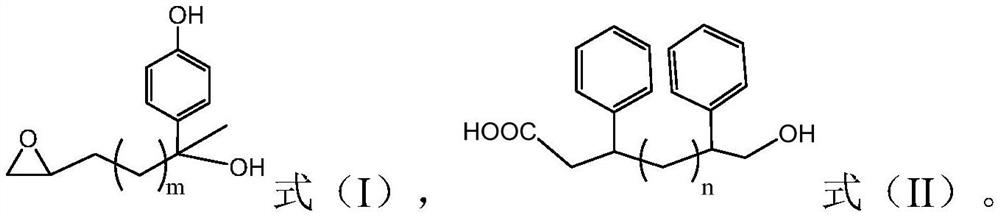

[0034] Among the present invention, the preparation method of described hyperbranched ester compound comprises the following steps:

[0035] (1) carry out ring-opening polymerization reaction with the hydroxy epoxy group phenol compound of structure shown in formula (I) in the presence of initiator, obtain polyhydroxyl hyperbranched precursor;

[0036] (2) Polycondensing polyhydroxy hyperbranched precursors and special hindered carboxylic acids having a structure shown in formula (II) under the catalytic action of an esterification catalyst to obtain hyperbranched ester compounds;

[0037]

[0038] In formula (I), m is an integer of 1-10, such as 1, 2, 3, 4, 5, 6, 7, 8, 9, 10. m is preferably an integer of 1-5, most preferably 1. When m is 1, the hydroxy epoxy phenolic compound is 4-(2-hydroxyl-4-(oxirane-2-alkyl) butyl) phenol, and its structural formula is as shown in formula (III) ;

[0039]

[0040] In formula (II), n is an integer of 0-10, such as 0, 1, 2, 3, 4, ...

preparation example 1

[0067] Preparation Example 1 This preparation example is used to illustrate the preparation of hyperbranched ester compounds

[0068] (1) Take 100 g of 4-(2-hydroxy-4-(oxirane-2-alkyl) butyl) phenol that has been dehydrated and deoxygenated in a Schlenk bottle, add 5 g potassium tert-butoxide, 5 g tert-butoxide Butanol and 50g tetrahydrofuran were reacted for 10h at a temperature of 50°C and a pressure of 0.25MPa under a nitrogen atmosphere to obtain a polyhydroxy hyperbranched precursor;

[0069] (2) Add 100g of polyhydroxy hyperbranched precursor and 600g of 5-hydroxy-3,4-diphenylpentanoic acid into a Schlenk bottle respectively, add 6g of concentrated sulfuric acid, and react at a temperature of 180°C and a pressure of 0.1MPa for 2h, Obtain hyperbranched ester compound, denoted as CZ-1.

preparation example 2

[0070] Preparation Example 2 This preparation example is used to illustrate the preparation of hyperbranched ester compounds

[0071] (1) Take 100 g of 4-(2-hydroxy-4-(oxirane-2-alkyl) butyl) phenol that has been dehydrated and deoxygenated in a Schlenk bottle, add 5 g potassium tert-butoxide, 5 g tert-butoxide Butanol and 50g tetrahydrofuran were reacted for 30h at a temperature of 60°C and a pressure of 0.25MPa under a nitrogen atmosphere to obtain a polyhydroxyl hyperbranched precursor;

[0072] (2) Add 100g of polyhydroxy hyperbranched precursor and 500g of 5-hydroxy-3,4-diphenylpentanoic acid into a Schlenk bottle, add 6g of concentrated sulfuric acid, and react at a temperature of 100°C and a pressure of 0.25MPa for 0.5h , to obtain hyperbranched ester compounds, denoted as CZ-2.

[0073] Preparation Example 3 This preparation example is used to illustrate the preparation of hyperbranched ester compounds

[0074](1) Take 100 g of 4-(2-hydroxy-4-(oxirane-2-alkyl) butyl)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com