Continuous fiber bundle reinforced composite material as well as preparation method and application thereof

A technology for reinforcing composite materials and continuous fibers, which is applied in the field of composite materials to achieve good compatibility, good weather resistance and aging resistance, and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

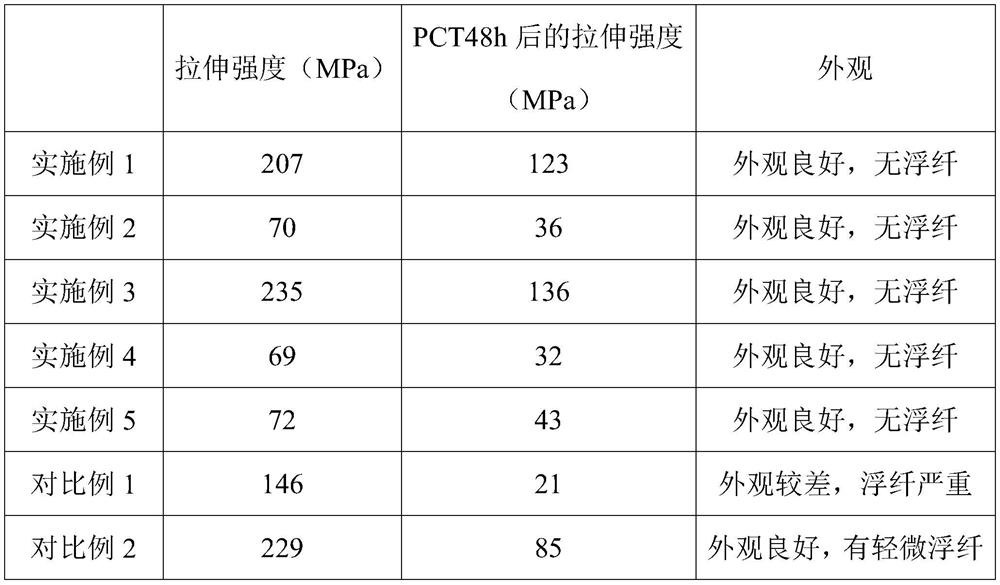

Examples

Embodiment 1

[0034] The continuous fiber bundle reinforced composite material in this embodiment includes a tape layer, and an upper film layer and a lower film layer arranged on the upper and lower sides of the tape layer, the tape layer contains continuous fiber bundles, and the upper film layer and the The lower film layer does not contain continuous fiber bundles.

[0035] In parts by weight, the tape layer contains 60 parts of PET (manufacturer Sinopec Yizheng Chemical Fiber Model FG600) and 40 parts of continuous glass fiber bundles.

[0036] The upper film is the same as the lower film, and in parts by weight, the upper film comprises the following components:

[0037] 90 pieces of PET

[0038] Titanium dioxide 9 parts

[0039] Anti-aging additive 1 part.

[0040] Among them, the matrix resin is the FG600 model of Sinopec Yizheng Chemical Fiber Factory, the titanium dioxide is the R-XXX of Kemu Company, and the anti-aging additive is tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl...

Embodiment 2

[0046] The continuous fiber bundle reinforced composite material of this embodiment includes a tape layer, and an upper film layer and a lower film layer arranged on the upper and lower sides of the tape layer, the tape layer contains continuous fiber bundles, and the upper film layer and the The lower film layer does not contain continuous fiber bundles.

[0047] In parts by weight, the tape layer contains 40 parts of PP (manufacturer Formosa Plastics model 3084H) and 60 parts of glass fiber bundles, and the tape layer is 3 layers.

[0048] The upper film is the same as the lower film, and in parts by weight, the upper film comprises the following components:

[0049] PP 89 parts

[0050] Titanium dioxide 10 parts

[0051] Anti-aging additive 1 part.

[0052] Among them, the matrix resin is polypropylene 3084H from Formosa Plastics, the titanium dioxide is R-105 from Kemu Company, and the anti-aging additive is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid ...

Embodiment 3

[0054] The continuous fiber bundle reinforced composite material of this embodiment includes a tape layer, and an upper film layer and a lower film layer arranged on the upper and lower sides of the tape layer, the tape layer contains continuous fiber bundles, and the upper film layer and the The lower film layer does not contain continuous fiber bundles.

[0055] In parts by weight, the tape layer contains 80 parts of PC (manufacturer Teijin Model L1250Y) and 20 parts of glass fiber bundles, and the tape layer is 4 layers.

[0056] The upper film is the same as the lower film, and in parts by weight, the upper film comprises the following components:

[0057] PC 95 copies

[0058] Titanium dioxide 4 parts

[0059] Anti-aging additive 1 part.

[0060] Among them, the matrix resin is Teijin's PC resin L-1250Y, the titanium dioxide is Kemu's R-350, and the anti-aging additive is polysuccinic acid (4-hydroxy-2,2,6,6-tetramethyl -1-piperidine ethanol) ester.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com