Weather-resistant matte-type high-strength PA6 and ASA alloy material and preparation method thereof

A technology of alloy materials and weathering matte grade, which is applied in the field of preparation of weathering matte grade high-strength PA6 and ASA alloy materials, can solve the problems of poor weather resistance, general strength, poor wear resistance and scratch resistance, etc., and achieve improved UV resistance Effect of Aging Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

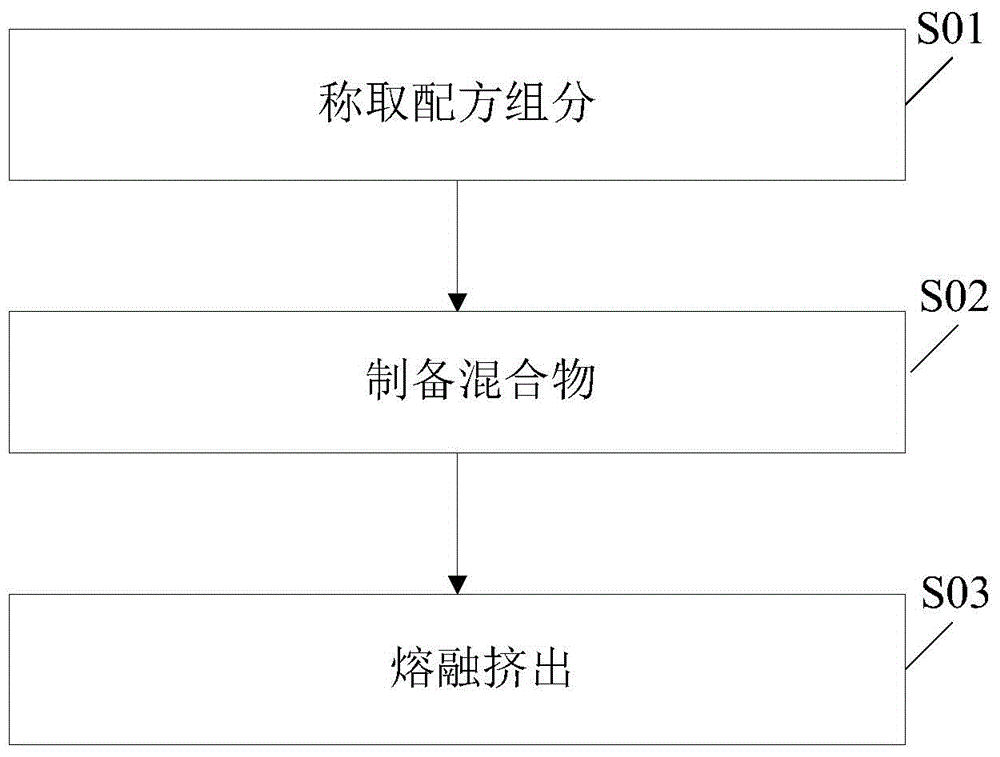

[0045] Correspondingly, the embodiment of the present invention provides a method for preparing weather-resistant matte-grade high-strength PA6 and ASA alloy materials. The flow chart of the preparation method is as follows figure 1 Shown, this preparation method comprises the steps:

[0046] S01, weighing formula components

[0047] Take said PA6 polypropylene, ASA, active nano-montmorillonite, compatibilizer, toughening agent, antioxidant, lubricant and carbon black respectively according to above-mentioned weather-resistant matte grade high-strength PA6 and ASA alloy material formula;

[0048] S02, prepare the mixture

[0049] Mix PA6 polypropylene, ASA, active nano-montmorillonite, compatibilizer, toughening agent, antioxidant, lubricant and carbon black in a medium-speed mixer for 5-10 minutes to obtain a mixture ;

[0050] S03, melt extrusion

[0051] The mixture and carbon fiber obtained in step S02 are blended in a twin-screw extruder, melt-extruded and granulated ...

Embodiment 1

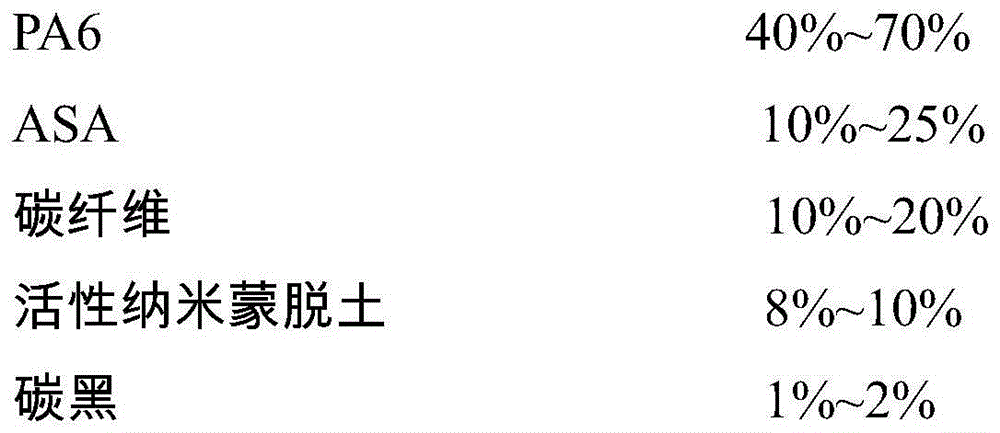

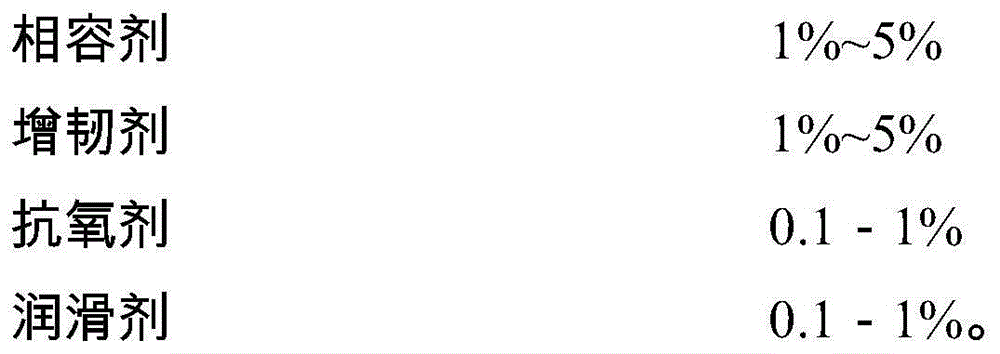

[0056] The weather-resistant matte grade high-strength PA6 and ASA alloy material of this embodiment, by weight, consist of the following components:

[0057] PA657%, ASA 15%, carbon fiber 10%, nano-montmorillonite 10%, carbon black 2%, compatibilizer 2%, toughening agent 3%, antioxidant 0.4%, lubricant 0.6%.

[0058] Its preparation method is as follows:

[0059] (1) take each component by above-mentioned parts by weight;

[0060] (2) PA6 polypropylene, ASA, active nanometer montmorillonite taken in step (1), compatibilizer, toughening agent, antioxidant, lubricant and carbon black are mixed in medium speed mixer for 5 -10 minutes to get the mixture;

[0061] (3) Blend the mixture obtained in step (2) and carbon fiber in a twin-screw extruder, then extrude and pelletize through a twin-screw extruder with a melting temperature of 220-250°C to obtain a weather-resistant matte grade High-strength PA6 and ASA alloy materials, in which carbon fiber is added through the side fib...

Embodiment 2

[0063] The weather-resistant matte grade high-strength PA6 and ASA alloy material of this embodiment, by weight, consist of the following components:

[0064] PA652%, ASA 15%, carbon fiber 15%, nano-montmorillonite 10%, carbon black 2%, compatibilizer 2%, toughening agent 3%, antioxidant 0.4%, lubricant 0.6%.

[0065] Its preparation method is as follows:

[0066] (1) take each component by above-mentioned parts by weight;

[0067] (2) PA6 polypropylene, ASA, active nanometer montmorillonite taken in step (1), compatibilizer, toughening agent, antioxidant, lubricant and carbon black are mixed in medium speed mixer for 5 -10 minutes to get the mixture;

[0068] (3) Blend the mixture obtained in step (2) and carbon fiber in a twin-screw extruder, then extrude and pelletize through a twin-screw extruder with a melting temperature of 220-250°C to obtain a weather-resistant matte grade High-strength PA6 and ASA alloy materials, in which carbon fiber is added through the side fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com