Continuous-long-fiber-reinforced/toughened PPS (polyphenylene sulfide) composite material and preparation method thereof

A composite material, strengthening and toughening technology, applied in the field of composite materials, can solve problems such as exposed glass fiber in products, and achieve the effects of stable production process, high surface quality and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Weigh PPS58% according to mass ratio, ethylene-maleic anhydride-glycidyl methacrylate terpolymer 5%, continuous long glass fiber 35%, antioxidant 1%, lubricant 1%, except long glass fiber Other materials are mixed in a high-speed mixer for 6 minutes at a mixing speed of 50r / min, and added from the hopper of the twin-screw extruder, and the long glass fiber is drawn and added at the first exhaust port, and then injection molded after melt extrusion and granulation. Tested according to ASTM standards.

Embodiment 2

[0019] Weigh PPS58% according to mass ratio, ethylene-maleic anhydride-glycidyl methacrylate terpolymer 5%, continuous long carbon fiber 35%, antioxidant 1%, lubricant 1%, other materials except long carbon fiber Mix in a high-speed mixer for 6 minutes at a mixing speed of 50r / min, add it from the hopper of the twin-screw extruder, add the long glass fiber at the first exhaust port after being drawn, and inject it after melt extrusion and granulation, according to ASTM standard test.

Embodiment 3

[0021] Weigh PPS58% by mass ratio, ethylene-maleic anhydride-glycidyl methacrylate terpolymer 5%, continuous long fiber 35% (continuous long carbon fiber 10%, continuous long glass fiber 25%), antioxidant 1%, lubricant 1%, other materials except long fibers were mixed in a high-speed mixer for 6 minutes at a mixing speed of 50r / min, added from the hopper of the twin-screw extruder, and the long fibers were added at the first exhaust port after traction , injection molding after melt extrusion granulation, tested according to ASTM standard.

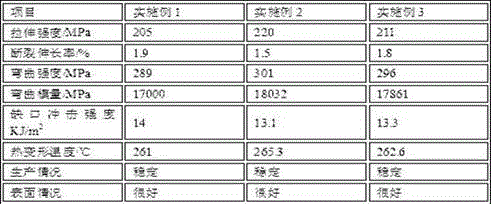

[0022] The product performance is shown in Table 1.

[0023]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com