High heat resistance and wear resistance glass fiber enhanced nylon material for engine and preparation method

A high heat resistance, engine technology, applied in wear-resistant glass fiber reinforced nylon material and preparation, high heat resistance field, can only be used for engine decorative cover, limit the application of glass fiber reinforced nylon, can not be used for oil pan and Intake pipe and other problems to achieve the effect of improving compatibility, convenient operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

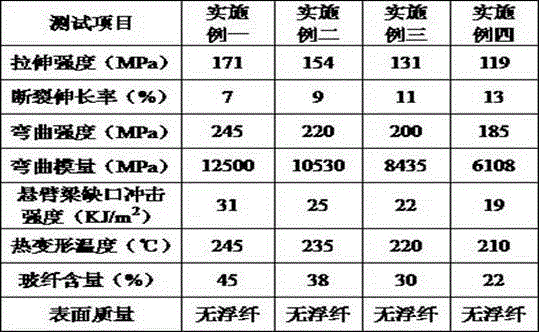

Embodiment 1

[0024] A glass fiber reinforced nylon material, weighed by mass percentage, 45 parts of high temperature nylon 6 (viscosity 2.6), 45 parts of glass fiber, 0.5 part of antioxidant, 0.5 part of heat stabilizer, 9 parts of maleic anhydride copolymer, 0.5 part 1 part anti-glass fiber exposure agent, 1% silicone masterbatch.

[0025] Its preparation method: accurately weigh the high-temperature nylon resin, antioxidant, heat stabilizer, glass fiber exposure prevention agent, and maleic anhydride copolymer in the formula according to the mass percentage, add it to a mixing pot at room temperature for blending, Take it out after blending evenly, and feed it into the extruder at a certain speed through the main feed port of the twin-screw extruder for mixing, and at the same time, pass the glass fiber into the extruder through the glass fiber feed port of the twin-screw extruder It can be extruded, cooled and pelletized, and the temperature of the extruder is 230~300°C.

Embodiment 2

[0027] A glass fiber reinforced nylon material, weighed by mass percentage, 53.4 parts of high temperature resistant nylon 6 (viscosity 2.6), 38 parts of glass fiber, 0.5 part of antioxidant, 0.5 part of heat stabilizer, 7.6 parts of maleic anhydride copolymer, 0.5 parts anti-glass fiber exposure agent, 1% silicone masterbatch.

[0028] Its preparation method: accurately weigh the high-temperature nylon resin, antioxidant, heat stabilizer, glass fiber exposure prevention agent, and maleic anhydride copolymer in the formula according to the mass percentage, add it to a mixing pot at room temperature for blending, Take it out after blending evenly, and feed it into the extruder at a certain speed through the main feed port of the twin-screw extruder for mixing, and at the same time, pass the glass fiber into the extruder through the glass fiber feed port of the twin-screw extruder It can be extruded, cooled and pelletized, and the temperature of the extruder is 230~300°C.

Embodiment 3

[0030] A glass fiber reinforced nylon material, weighed by mass percentage, 63 parts of high temperature resistant nylon 6 (viscosity 2.6), 30 parts of glass fiber, 0.5 part of antioxidant, 0.5 part of heat stabilizer, 6 parts of maleic anhydride copolymer, 0.5 parts anti-glass fiber exposure agent, 1% silicone masterbatch.

[0031] Its preparation method: accurately weigh the high-temperature nylon resin, antioxidant, heat stabilizer, glass fiber exposure prevention agent, and maleic anhydride copolymer in the formula according to the mass percentage, add it to a mixing pot at room temperature for blending, Take it out after blending evenly, and feed it into the extruder at a certain speed through the main feed port of the twin-screw extruder for mixing, and at the same time, pass the glass fiber into the extruder through the glass fiber feed port of the twin-screw extruder It can be extruded, cooled and pelletized, and the temperature of the extruder is 230~300°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com