Low temperature and impact resistant PC composite material and its preparation and application in air conditioner shell

A composite material and impact-resistant technology, which is applied in the field of low-temperature-resistant and impact-resistant PC composite materials and its preparation and application in air-conditioning shells, can solve the impact of PC resin impact performance, low-temperature impact resistance reduction, unfavorable PC composite materials, etc. problems, to achieve excellent mechanical properties, excellent impact resistance, and comprehensive quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

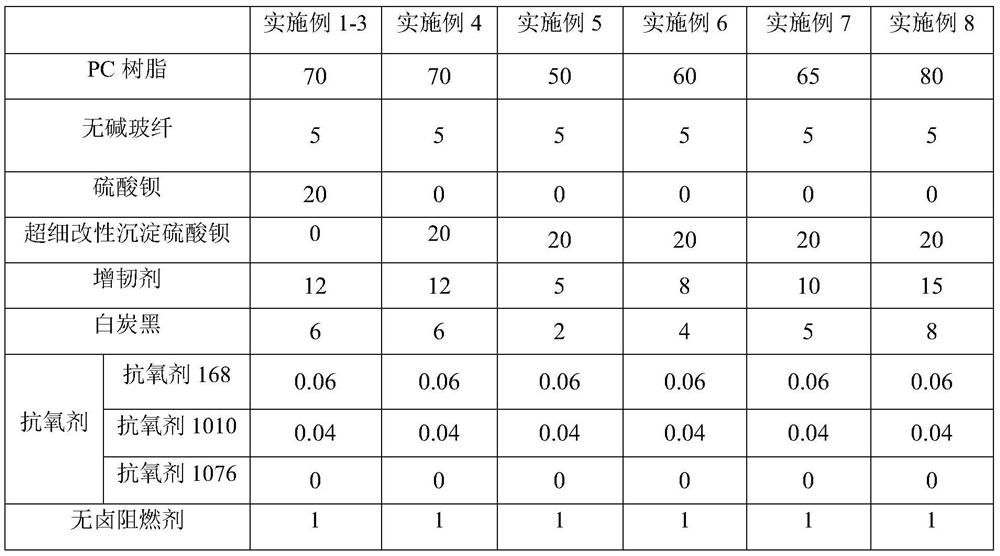

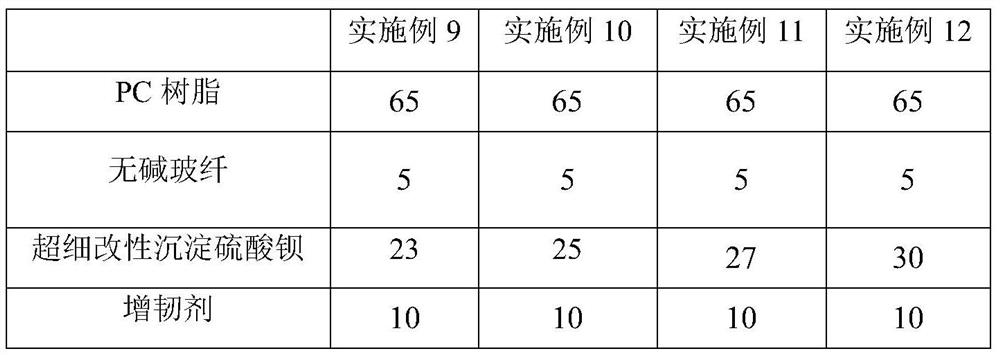

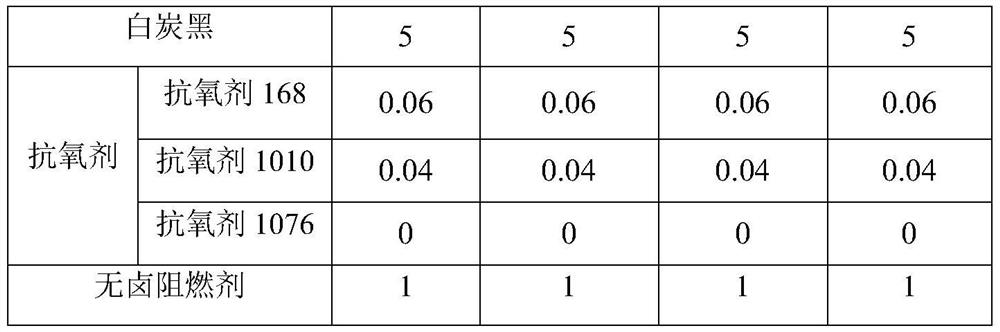

Examples

preparation example

[0043] The toughening agent used in the present invention is obtained through the following processing operations to the metallocene ethylene-octene copolymer:

[0044] Add commercially available metallocene ethylene-octene copolymer into the ozone generator, and control the gas flow in the ozone generator to be 0.1m 3 / h, the ozone concentration was 55 mg / L, the molar ratio of ozone to metallocene ethylene-octene copolymer was 1.3:1, and the treatment was performed for 100 min to obtain the toughening agent metallocene ethylene-octene copolymer after ozonation reaction treatment. Wherein, the molar ratio of ozone to metallocene ethylene-octene copolymer can also be 1:1, 2:1, etc., mainly ensuring that the molar amount of ozone is not less than the molar amount of metallocene ethylene-octene copolymer.

[0045] The white carbon black in the present invention is the pretreated white carbon black, and the concrete processing operation is:

[0046] The commercially available whi...

Embodiment 1

[0050] A low-temperature-resistant and impact-resistant PC composite material is prepared by the following operations:

[0051] (1) According to the dosage shown in Table 1, add PC resin, toughening agent and white carbon black to the mixer and mix, and mix at 225°C for 45min to obtain material A;

[0052] (2) add barium sulfate and alkali-free glass fiber to material A, stir to obtain material B;

[0053] (3) Add antioxidant and halogen-free flame retardant to material B, melt and mix at 230° C. for 5 minutes to obtain material C;

[0054] (4) Add material C into the twin-screw extruder, control the temperature of the front section of the barrel to be 240 °C, the temperature of the middle section to be 230 °C, the temperature of the rear section to be 220 °C, the temperature of the die to be 90 °C, the speed of the main engine to be 350r / min, and the extruder The granulation is carried out to obtain a low temperature and impact resistant PC composite material.

Embodiment 2

[0056] A low-temperature-resistant and impact-resistant PC composite material is prepared by the following operations:

[0057] (1) According to the dosage shown in Table 1, add PC resin, toughening agent and white carbon black to the mixer and mix, and mix at 235°C for 45min to obtain material A;

[0058] (2) adding barium sulfate and alkali-free glass fiber to material A, stirring evenly to obtain material B;

[0059] (3) Add antioxidant and halogen-free flame retardant to material B, melt and mix at 238° C. for 5 minutes to obtain material C;

[0060] (4) Add material C into the twin-screw extruder, control the temperature of the front section of the barrel to be 240 °C, the temperature of the middle section to be 230 °C, the temperature of the rear section to be 220 °C, the temperature of the die to be 90 °C, the speed of the main engine to be 350r / min, and the extruder The granulation is carried out to obtain a low temperature and impact resistant PC composite material. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com