Thermal aging resistant PET modified material and its preparation method

A modified material and heat-resistant aging technology, which is applied in the field of heat-resistant aging PET modified material and its preparation, can solve the problems of insufficient heat-resistant aging and low heat resistance, and achieve good surface gloss and good physical comprehensive properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

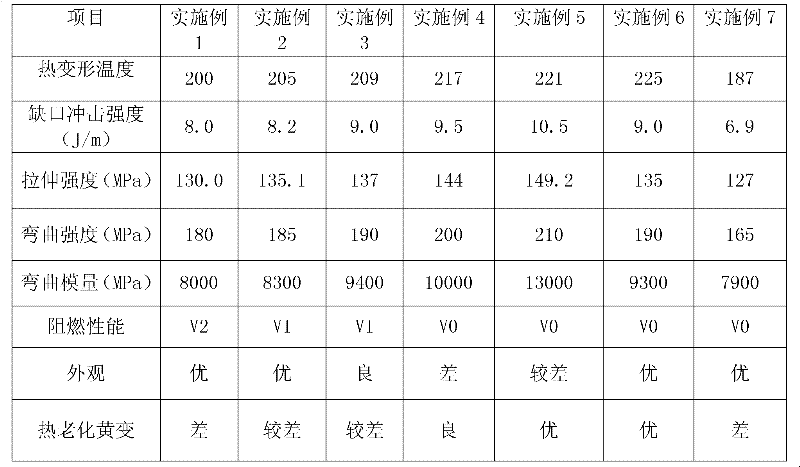

Examples

Embodiment 1

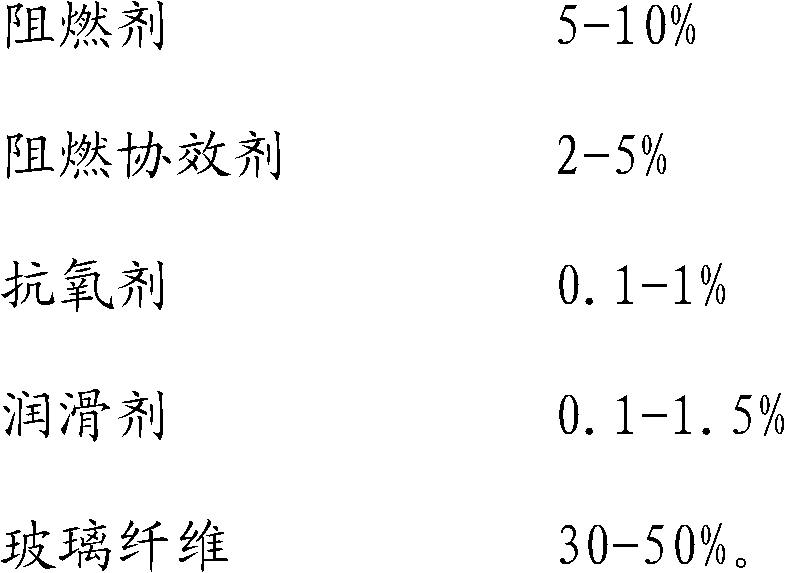

[0020] The heat-resistant aging PET modified material of this embodiment, by weight percentage, is made up of following components:

[0021] PET 62%; nucleating agent 0.3%; flame retardant 5%; flame retardant synergist 2%; antioxidant 0.2%; lubricant 0.5%; glass fiber 30%.

[0022] Its preparation method is as follows:

[0023] Step 1, each component is weighed by the above-mentioned percentage by weight;

[0024] Step 2, mixing the weighed PET, nucleating agent, flame retardant, flame retardant synergist, antioxidant, and lubricant in a medium speed mixer for 3 minutes;

[0025] Step 3. Put the mixed material in step 2 into the twin-screw extruder and mix it with the weighed glass fiber, melt and extrude, and granulate; the production process conditions are: the temperatures in each zone of the twin-screw extruder are respectively : The temperature in the first zone is 200°C, the temperature in the second zone is 240°C, the temperature in the third zone is 255°C, the temper...

Embodiment 2

[0027] The heat-resistant aging PET modified material of this embodiment, by weight percentage, is made up of following components:

[0028] PET 55.1%; nucleating agent 0.4%; flame retardant 6.6%; flame retardant synergist 2.6%; antioxidant 0.2%; lubricant 0.1%; glass fiber 35%.

[0029] Its preparation method is as follows:

[0030] Step 1, each component is weighed by the above-mentioned percentage by weight;

[0031] Step 2, mixing the weighed PET, nucleating agent, flame retardant, flame retardant synergist, antioxidant, and lubricant in a medium speed mixer for 5 minutes;

[0032] Step 3. Put the mixed material in step 2 into the twin-screw extruder and mix it with the weighed glass fiber, melt and extrude, and granulate; the production process conditions are: the temperatures in each zone of the twin-screw extruder are respectively : The temperature in the first zone is 200°C, the temperature in the second zone is 230°C, the temperature in the third zone is 245°C, the ...

Embodiment 3

[0034] The heat-resistant aging PET modified material of this embodiment, by weight percentage, is made up of following components:

[0035] PET 49.2%; nucleating agent 0.5%; flame retardant 6.4%; flame retardant synergist 2.4%; antioxidant 1%; lubricant 1.5%; glass fiber 39%.

[0036] Its preparation method is as follows:

[0037] Step 1, each component is weighed by the above-mentioned percentage by weight;

[0038] Step 2, mixing the weighed PET, nucleating agent, flame retardant, flame retardant synergist, antioxidant, and lubricant in a medium speed mixer for 7 minutes;

[0039] Step 3. Put the mixed material in step 2 into the twin-screw extruder and mix it with the weighed glass fiber, melt and extrude, and granulate; the production process conditions are: the temperatures in each zone of the twin-screw extruder are respectively : The temperature in the first zone is 205°C, the temperature in the second zone is 240°C, the temperature in the third zone is 245°C, the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com