Modified polypropylene material with low molding shrinkage and without buckling deformation and preparation method of modified polypropylene material

A polypropylene material and shrinkage rate technology, applied in the field of modified polypropylene material and its preparation, can solve the problems of small difference in numerical value and small shrinkage rate, and achieve the effects of balanced toughness, excellent rigidity and no floating fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

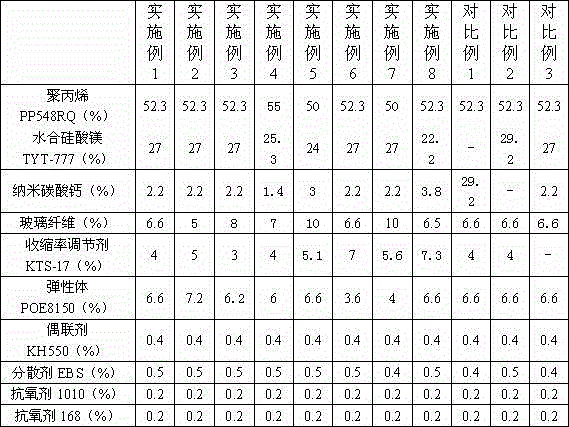

[0029] The present invention will be further described in detail below in conjunction with specific examples. The test methods used in the following examples are conventional methods unless otherwise specified; the raw materials and reagents used, if not otherwise specified, are commercially available raw materials and reagents such as commercially available.

[0030] In the embodiment, the relative density of the polypropylene used is 0.9~0.93g / cm 3 , the melt flow rate is 15~25 g / 10min (190°C, 2.16kg), the horizontal shrinkage rate is 1.3%~1.7%, and the vertical shrinkage rate is 1.4%~1.8%. You can choose PP548RQ produced by Yanshan Petrochemical, which is relatively The density is 0.91g / cm 3 , the melt flow rate is 23 g / 10min (190°C, 2.16kg), and the vertical and horizontal shrinkage rates are 1.46% and 1.50% respectively;

[0031] The filler is a composition of hydrated magnesium silicate and light calcium carbonate;

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com