Lightweight high-strength flame-retardant composite material for high-speed train carriage and preparation method thereof

A technology for flame-retardant composite materials and high-speed trains, applied in the field of high-speed rail-related materials, can solve the problems of material physical properties and surface finish not meeting requirements, decreased compatibility between polyester and glass fiber, and high material costs, etc. Achieve the effect of controllable production process, good compatibility and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

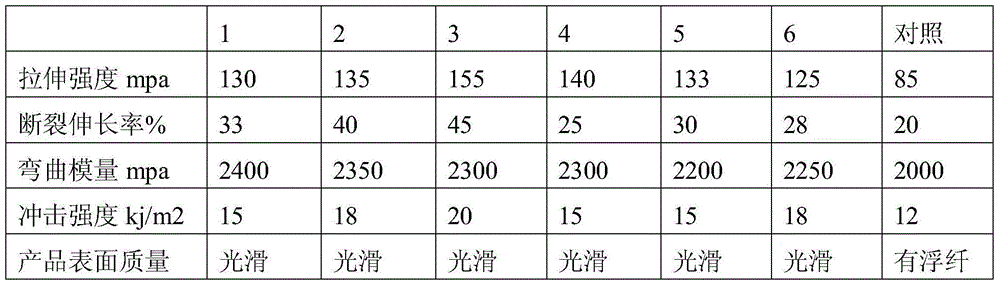

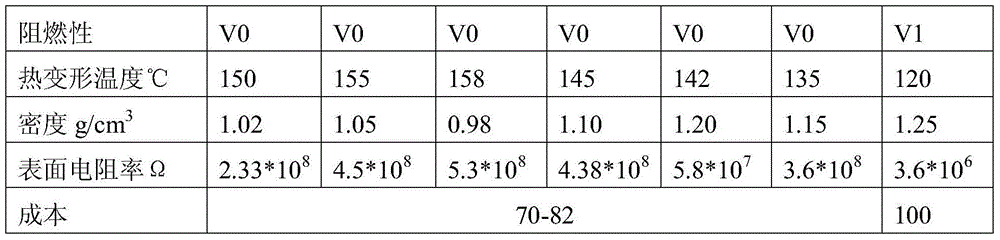

Examples

Embodiment 1

[0014] A light-weight, high-strength flame-retardant composite material for high-speed train carriages, which consists of the following components in parts by weight: glass fiber 30, homopolymer PP resin 55, carbon fiber 10, silane coupling agent 2, Malay Anhydride grafted PP3, phenoxytetrabromobisphenol A polycarbonate oligomer 5, corundum 6, phosphite antioxidant 168 1.0, stearate 1, cerium oxide 0.3, hindered amine light stabilizer 0.2.

[0015] The preparation method of the above-mentioned lightweight high-strength flame-retardant composite material for high-speed train carriages comprises the following steps:

[0016] Step 1: Weigh each component according to the proportioning ratio;

[0017] Step 2: Mix other components except glass fiber in a high-speed mixer for 3-5 minutes.

[0018] Step 3: Put the above homogeneously mixed mixture in a twin-screw extruder, melt and mix and extrude it, and add glass fibers into the twin-screw extruder with a vibrating metering devic...

Embodiment 2

[0020] A light-weight, high-strength flame-retardant composite material used in high-speed train carriages. It consists of the following components in parts by weight: glass fiber 35, homopolymer PP resin 55, carbon fiber 12, silane coupling agent 2, Malay Anhydride grafted PP4, phenoxy tetrabromobisphenol A polycarbonate oligomer 4, corundum 6, phosphite antioxidant 168 0.8, stearate 2, cerium oxide 0.3, hindered amine light stabilizer 0.25.

[0021] The method for preparing the above-mentioned lightweight high-strength flame-retardant composite material for high-speed train carriages is characterized in that,

[0022] Step 1: Weigh each component according to the proportioning ratio;

[0023] Step 2: Mix other components except glass fiber in a high-speed mixer for 3-5 minutes;

[0024] Step 3: Put the above homogeneously mixed mixture in a twin-screw extruder, melt and mix and extrude it, and add glass fibers into the twin-screw extruder with a vibrating metering device. ...

Embodiment 3

[0026] A light-weight, high-strength flame-retardant composite material for high-speed train carriages, which consists of the following components in parts by weight: glass fiber 35, homopolymer PP resin 55, carbon fiber 12, silane coupling agent 3, Malay Anhydride grafted PP3, phenoxytetrabromobisphenol A polycarbonate oligomer 5, corundum 5, phosphite antioxidant 168 1.0, stearate 3, cerium oxide 0.4, hindered amine light stabilizer 0.3.

[0027] The method for preparing the above-mentioned lightweight high-strength flame-retardant composite material for high-speed train carriages is characterized in that,

[0028] Step 1: Weigh each component according to the proportioning ratio;

[0029] Step 2: Mix other components except glass fiber in a high-speed mixer for 3-5 minutes;

[0030] Step 3: Put the above homogeneously mixed mixture in a twin-screw extruder, melt and mix and extrude it, and add glass fibers into the twin-screw extruder with a vibrating metering device. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com