A kind of lightweight ski helmet material and preparation method thereof

A helmet and lightweight technology, applied in the field of materials, can solve the problems of high shrinkage, unstable size of molded products, low strength of high-density polyethylene materials, etc., to enhance the adhesion of paint films, improve dimensional stability and durability Thermal property, strong adhesion of paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

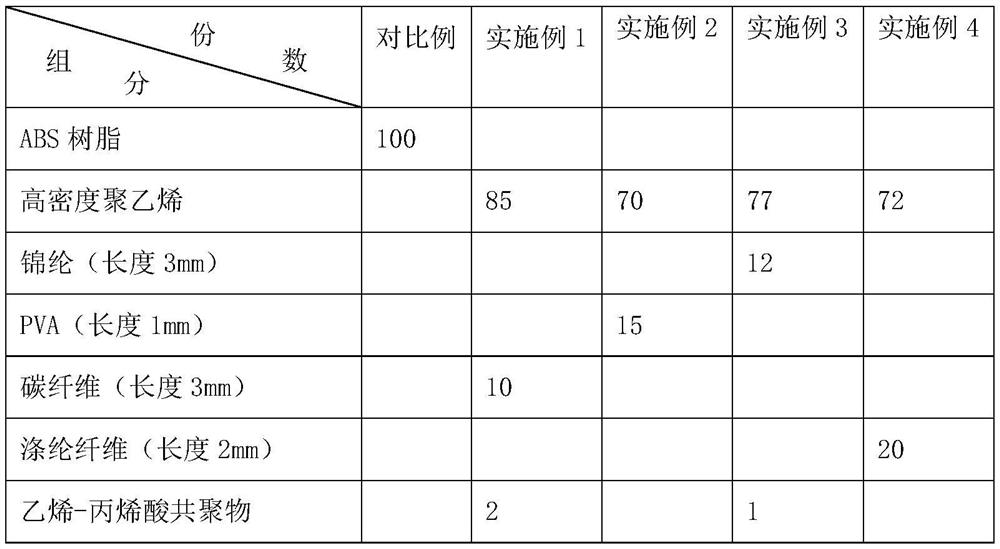

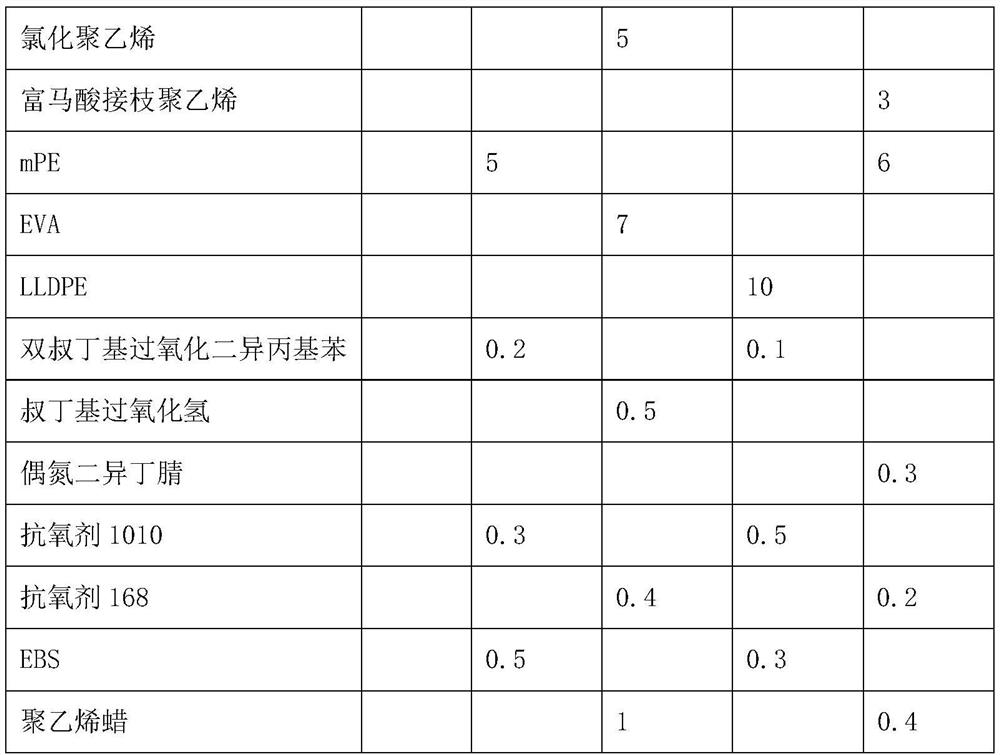

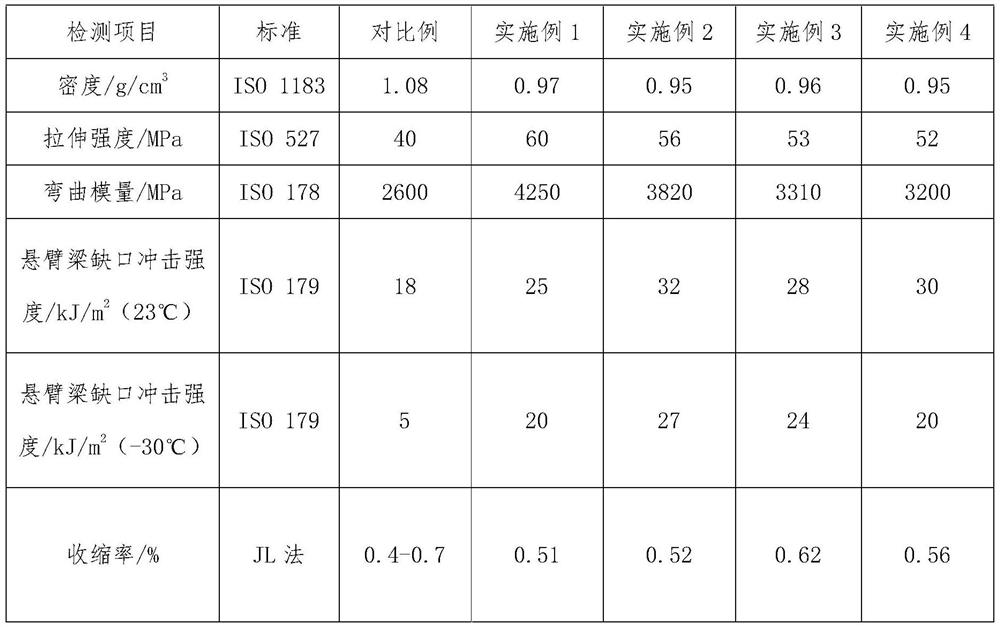

Embodiment 1

[0034] A preparation method for lightweight ski helmet material, comprising the following steps:

[0035] Step 1: 85 parts of high-density polyethylene with a melt index of 1g / 10min, 5 parts of mPE, 2 parts of ethylene-acrylic acid copolymer, 0.2 part of dicumyl peroxide, and 0.3 part of antioxidant 1010 , 0.5 part of EBS was added to the high-speed mixer according to the parts by weight, and pre-mixed for 1-3 minutes to obtain the mixture;

[0036] Step 2: Add the mixture obtained in Step 1 into the twin-screw extruder through the hopper, and add 10 parts of carbon fibers with a fiber length of 3mm into the extruder through the side feeder, and plasticize through meshing, mixing, extrusion, drawing strips, air-dried, and granulated to obtain high-strength, high-heat-resistant polyethylene composite materials; the temperature of the extruder from the first zone to the head: 160-200°C;

[0037] Step 3: Add the composite material obtained in Step 2 to an injection molding machi...

Embodiment 2

[0039] A preparation method for lightweight ski helmet material, comprising the following steps:

[0040] Step 1: 70 parts of high-density polyethylene with a melt index of 2g / 10min, 7 parts of EVA, 5 parts of chlorinated polyethylene, 0.5 part of tert-butyl hydroperoxide, 0.4 part of antioxidant 168, and 1 part of polyethylene wax Add it into the high-speed mixer according to the parts by weight, and pre-mix for 1-3 minutes to obtain the mixture;

[0041] Step 2: Add the mixture obtained in Step 1 into the twin-screw extruder through the hopper, and add 15 parts of PVA with a fiber length of 1mm into the extruder through the side feeder, and plasticize through meshing, mixing, extrusion, drawing strips, air-dried, and granulated to obtain high-strength, high-heat-resistant polyethylene composite materials; the temperature of the extruder from the first zone to the head: 160-200°C;

[0042] Step 3: Add the composite material obtained in Step 2 to an injection molding machine,...

Embodiment 3

[0044] A preparation method for lightweight ski helmet material, comprising the following steps:

[0045] Step 1: 77 parts of high-density polyethylene with a melt index of 10g / 10min, 10 parts of LLDPE, 1 part of ethylene-acrylic acid copolymer, 0.1 part of dicumyl peroxide, and 0.5 part of antioxidant 1010, Add 0.3 parts of EBS into the high-speed mixer according to the parts by weight, and pre-mix for 1-3 minutes to obtain the mixture;

[0046] Step 2: Add the mixture obtained in Step 1 into the twin-screw extruder through the hopper, and add 12 parts of nylon with a fiber length of 3 mm into the extruder through the side feeder, and plasticize, mix, extrude, and draw strips, air-dried, and granulated to obtain high-strength, high-heat-resistant polyethylene composite materials; the temperature of the extruder from the first zone to the head: 160-200°C;

[0047]Step 3: Add the composite material obtained in Step 2 to an injection molding machine, and obtain a lightweight sk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com