UV adhesive for sealing quantum dot material, and preparation method thereof

A technology of quantum dot material and parts by weight, which is applied in the field of sealants, can solve the problems of low bond strength and poor water and oxygen barrier performance of sealants, and achieve the effects of comprehensive performance improvement, low shrinkage adhesion, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

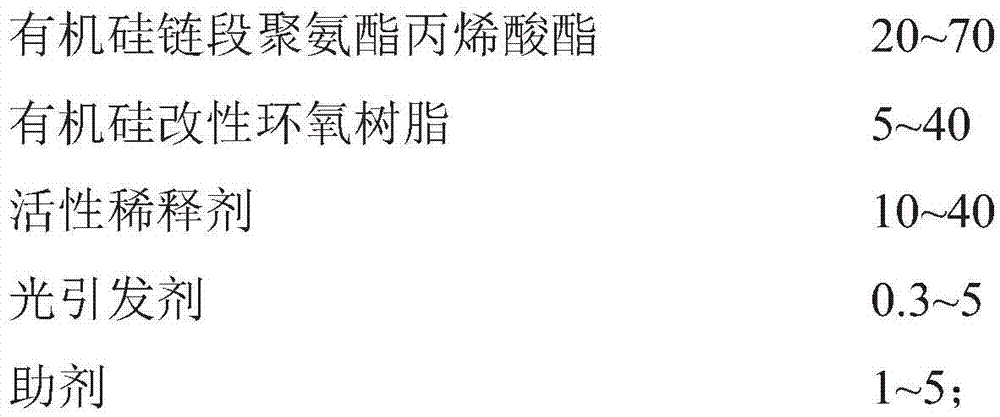

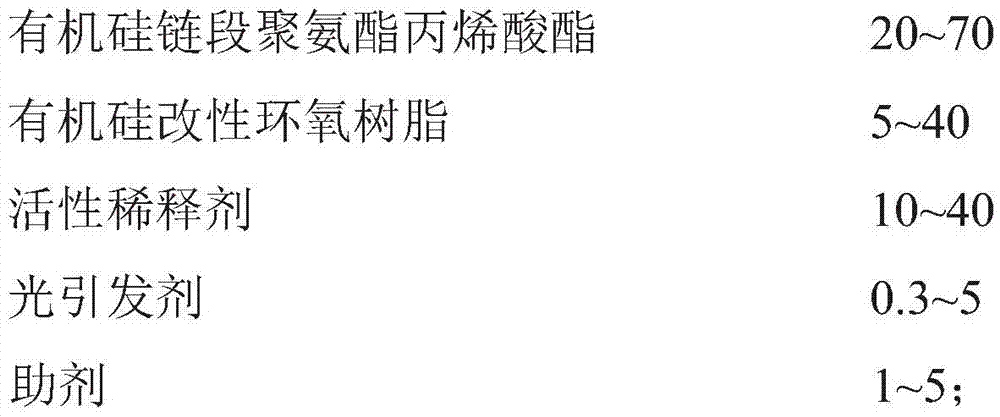

[0035] Embodiment 1: The UV glue used for quantum dot material sealing provided by the present embodiment is prepared by the following components in parts by weight:

[0036]

[0037]

[0038] Wherein, the organosilicon segmented urethane acrylate is a modified polyurethane resin with a polysiloxane segment as the main chain and a methacrylate double bond functional group as an end group; the organosilicon-modified epoxy resin is The polysiloxane segment is the main chain, and the epoxy functional group is the modified silicone resin.

[0039] The polysiloxane is phenyl silicone oil containing active hydrogen end groups, methyl vinyl silicone oil, methyl ethoxy silicone oil, methyl silicone oil or ethyl silicone oil.

[0040]The reactive diluent contains a monofunctional or bifunctional monomer of methacrylate double bond functional group, wherein: the monofunctional group containing methacrylate double bond functional group is isooctyl acrylate, lauryl methacrylate, met...

Embodiment 2

[0053] Embodiment 2: the UV glue used for quantum dot material sealing provided by this embodiment, and the preparation method of this UV glue, its components and steps are basically the same as Example 1, and its difference is:

[0054] A kind of UV glue that is used for quantum dot material sealing, it is prepared by mixing the following components by weight:

[0055]

[0056]

[0057] A kind of preparation method of the UV glue that is used for quantum dot material sealing, it comprises the following steps:

[0058] (1) preparing organosilicon segmented urethane acrylate;

[0059] (2) prepare organosilicon modified epoxy resin;

[0060] (3) prepare each component by following parts by weight:

[0061]

[0062] (4) prepare a planetary vacuum mixer, the organosilicon segment polyurethane acrylate prepared in step (3), organosilicon modified epoxy resin, isobornyl acrylate, hydroxyethyl acrylate, 1-hydroxycyclohexyl Phenyl ketone, TEGO Airex931, 2,6-bis(octadecyl)-...

Embodiment 3

[0066] Embodiment 3: the UV glue used for quantum dot material sealing provided by this embodiment, and the preparation method of this UV glue, its components and steps are basically the same as those in Examples 1 and 2, except that:

[0067] A kind of UV glue that is used for quantum dot material sealing, it is prepared by mixing the following components by weight:

[0068]

[0069] A kind of preparation method of the UV glue that is used for quantum dot material sealing, it comprises the following steps:

[0070] (1) preparing organosilicon segmented urethane acrylate;

[0071] (2) prepare organosilicon modified epoxy resin;

[0072] (3) prepare each component by following parts by weight:

[0073]

[0074] (4) prepare a planetary vacuum mixer, the organosilicon segment polyurethane acrylate prepared in the step (3), organosilicon modified epoxy resin, lauryl methacrylate, methacrylate hydroxypropyl ester, 2 , 4,6-trimethylbenzoyl-diphenylphosphine oxide, BYK-320, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com